Automatic machining equipment for five-star feet

An automatic processing, five-star technology, applied in metal processing equipment, drilling/drilling equipment, metal processing machinery parts, etc., can solve problems such as surface darkening, reduce labor intensity, ensure safety, ensure processing quality and The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention will be further described below in conjunction with the embodiments in the accompanying drawings.

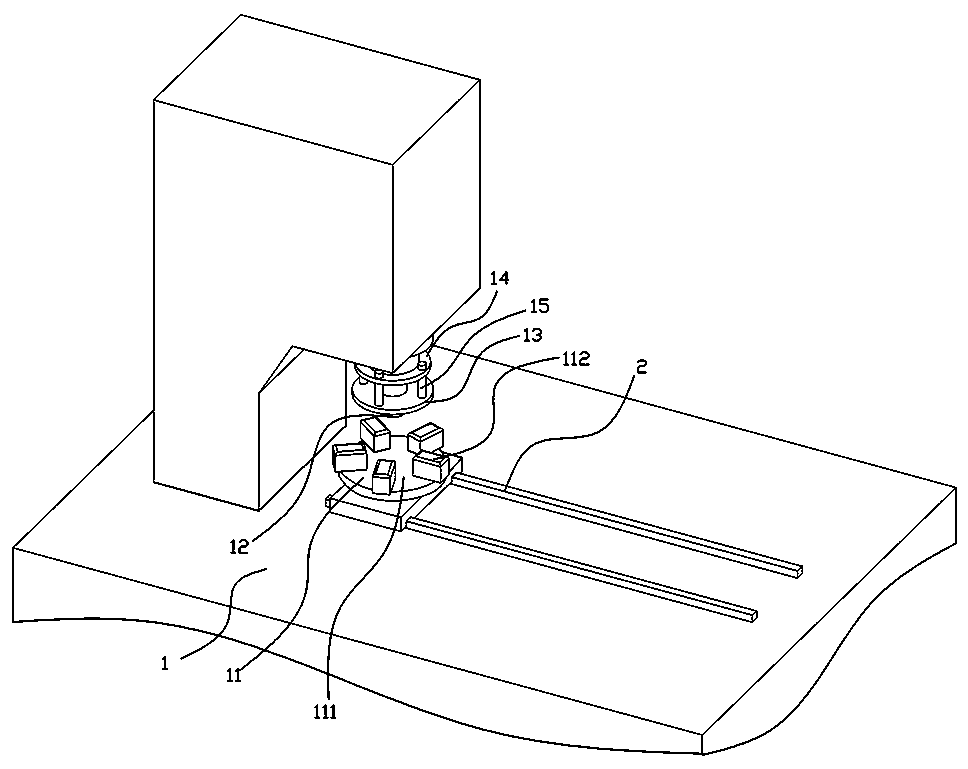

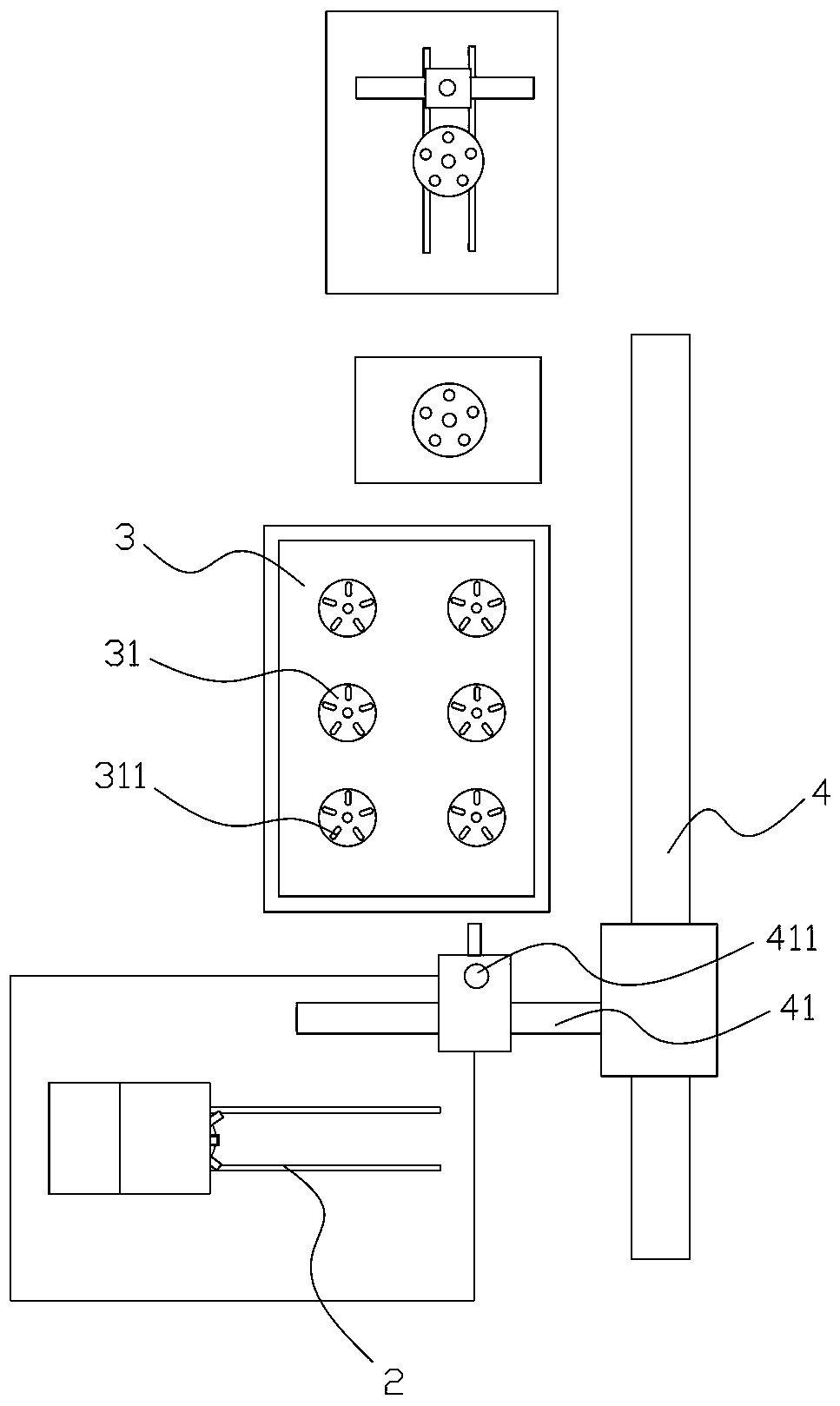

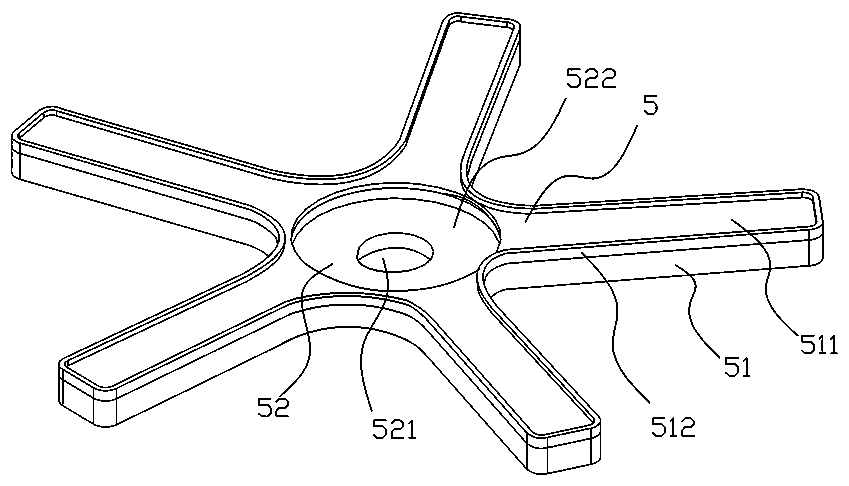

[0023] like Figure 1 to Figure 4 The five-star base automatic processing equipment shown includes a drilling machine 1. The drilling machine 1 includes a base 11 and a drill 12 that is movable relative to the base 11 at the upper end of the base 11. The base 11 includes a body 111 and a uniform The position-limiting protrusion 112 arranged on the body 111, the first position-limiting body 13 is provided with an opening and is set on the outside of the drill bit 12, the first position-limiting body 13 and the second position-limiting body 14 are provided with bolts 15, and the bolts 15 is arranged parallel to the translational direction of the drill bit 12, and a compression spring is sleeved on the bolt 15 between the first limiting body 13 and the second limiting body 14. During the processing, the drill bit 12 is inserted into the center body of the five...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com