Oat enzyme deactivation treatment method and oat

A treatment method, oat technology, applied in food heat treatment, seed preservation by radiation/electrical treatment, heat preservation of seeds, etc., can solve the conflict between the effect of enzyme inactivation and oat quality, and achieve the maintenance of quality stability and flavor And the effect of good texture and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

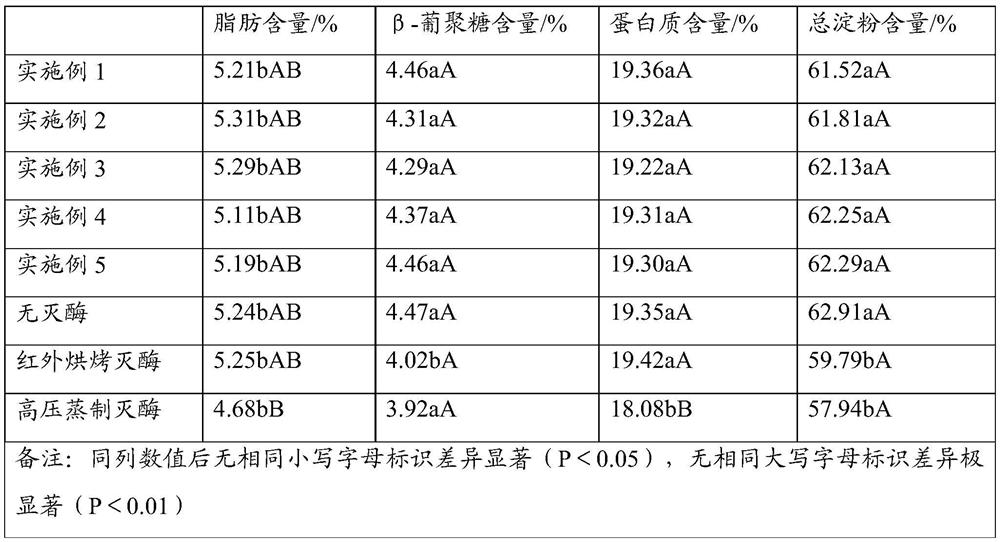

Examples

Embodiment 1

[0032] Carry out moistening treatment to 2kg of oat grains, control the water content to 27%; tile the oat grains after moistening treatment for electron beam radiation treatment, control the dose of electron beam radiation to 0.5kGy, and the radiation time is 6s; The final oat grains are subjected to two-stage ultrasonic steam treatment to inactivate enzymes; among them, the temperature of the first stage steam treatment is controlled at 130°C, the treatment time is 10s, and the steam flow rate is 10m 3 / h; the temperature of the second steam treatment is controlled at 180°C, the treatment time is 25s, and the steam flow rate is 30m 3 / h, and combined with ultrasonic treatment in the second steam treatment process; the ultrasonic power is controlled to 600W, and the ultrasonic action is controlled to be every ultrasonic action 4s intermittent 6s; the oat grains after the enzyme removal are cooled to normal temperature at room temperature Store in vacuum.

Embodiment 2

[0034] Carry out moistening treatment to 2kg of oat grains, and control the water content to 32%; spread the oat grains after moistening treatment for electron beam radiation treatment, control the dose of electron beam radiation to 3kGy, and the radiation time is 2s; The oat grains were subjected to two-stage ultrasonic steam treatment to inactivate enzymes; among them, the temperature of the first steam treatment was controlled at 160°C, the treatment time was 5s, and the steam flow rate was 5m 3 / h; the second steam treatment temperature is controlled at 200°C, the treatment time is 15s, and the steam flow rate is 20m 3 / h, and combined with ultrasonic treatment in the second steam treatment process; the ultrasonic power is controlled to 700W, and the ultrasonic action is controlled to be 4s and 6s for each ultrasonic action; the oat grains after the enzyme removal are cooled to normal temperature and stored in a vacuum .

Embodiment 3

[0036] Carry out moistening treatment to 2kg of oat grains, and control the water content to 30%; spread the oat grains after moistening treatment for electron beam radiation treatment, control the dose of electron beam radiation to 1.5kGy, and the radiation time is 5s; The final oat grains are subjected to two-stage ultrasonic steam treatment to inactivate enzymes; among them, the temperature of the first stage steam treatment is controlled at 150°C, the treatment time is 8s, and the steam flow rate is 8m 3 / h; the temperature of the second steam treatment is controlled at 190°C, the treatment time is 20s, and the steam flow rate is 25m 3 / h, and combined with ultrasonic treatment in the second steam treatment process; the ultrasonic power is controlled to 700W, and the ultrasonic action is controlled to be 4s and 6s for each ultrasonic action; the oat grains after the enzyme removal are cooled to normal temperature and stored in a vacuum .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com