Method for recycling valuable metal from cobalt white alloy

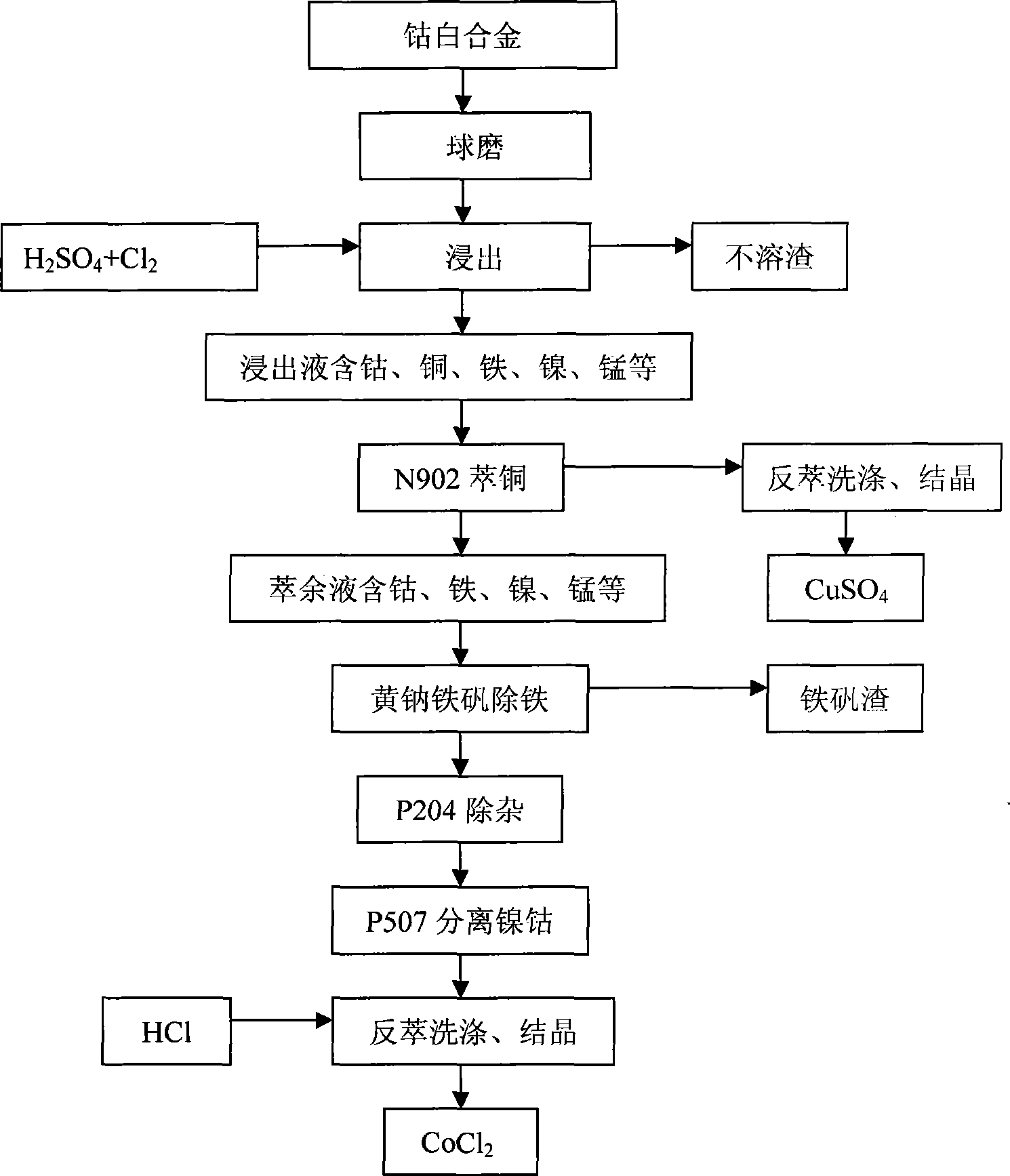

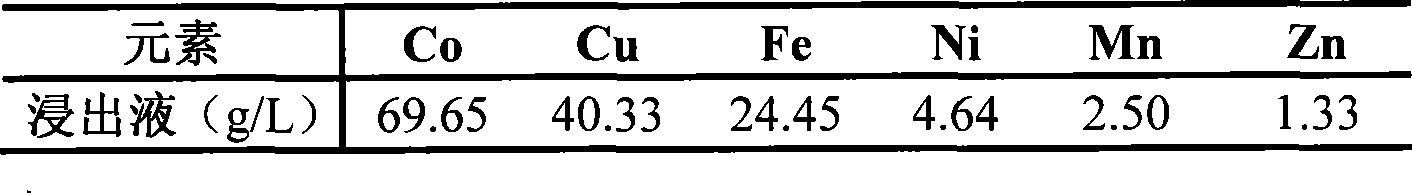

A cobalt white alloy and valuable metal technology, applied in the direction of improving process efficiency, can solve the problems of unformed processing technology, low metal leaching rate, only 90%, etc., and achieve high added value of products, high recovery rate, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

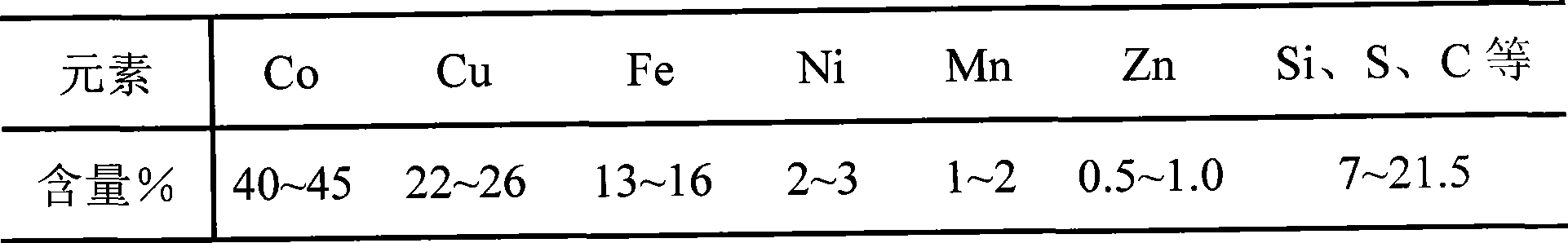

[0022] After the cobalt white alloy is ball-milled, weigh 300g of the 80-mesh sieve and add it into a three-necked flask with a volume of 3L; configure 1.8L of 2mol / L sulfuric acid and pour it into the same flask. Put the beaker into a constant temperature water bath, adjust the temperature to 90°C, keep mechanical stirring, and adjust the speed to 800 rpm. Then feed chlorine gas into the three-necked bottle at a flow rate of 1L / min. After the unreacted chlorine gas overflows, it can be absorbed by lye or recycled. After reacting for 5 hours, after filtering, the filtrate was settled to 2.0L, and adopted EDTA complexometric titration, flame atomic absorption spectrometry and plasma emission spectrometry (ICP) to detect metal element content in the leachate as follows:

[0023]

[0024] After calculation, the leaching rates of cobalt, copper and iron are 99.5%, 99.6% and 99.8% in sequence.

Embodiment 2

[0026] Take 1 L of the filtrate of Example 2, configure 1 L of organic phase (the composition is 20% N902 + 80% 260# solvent oil), perform two-stage countercurrent extraction, and control the extraction equilibrium pH value to 2.0. After the extraction and separation, the remaining aqueous solution was settled to the original volume, and the metal element content was detected by EDTA complexometric titration, flame atomic absorption spectrometry and plasma emission spectrometry (ICP) as follows:

[0027]

[0028] That is, the copper in the solution is basically extracted into the organic phase, and the nickel, cobalt and manganese are slightly lost. The extraction rate of copper is calculated to be 99.5%.

[0029] The organic phase is back-extracted with sulfuric acid to obtain a copper sulfate solution of about 40g / l, and the copper sulfate product is obtained after crystallization. The quality analysis of the product is as follows:

[0030]

[0031] It meets the requ...

Embodiment 3

[0033] Get 500ml of the raffinate in Example 2 and put it into a three-necked flask, add 2.40g of oxidant sodium chlorate, and add an appropriate amount of NaOH to adjust the pH value of the system to 1.5; put the flask into a constant temperature water bath, and adjust the temperature to 90 ℃, keep mechanical stirring, the stirring intensity is 500 rpm, after the yellow precipitate precipitates, add NaOH appropriately, keep the pH value of the system between 2.0 and 2.5, react for 2 hours, filter and wash the solution for several times Capacity to 1L, adopt EDTA complexometric titration, flame atomic absorption spectrometry and plasma emission spectrometry (ICP) to detect its metal element content as follows:

[0034]

[0035] That is, only a small amount of iron remains in the solution, and cobalt is slightly lost. After calculation, the iron removal rate is 98.5%, and the iron removal effect is better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com