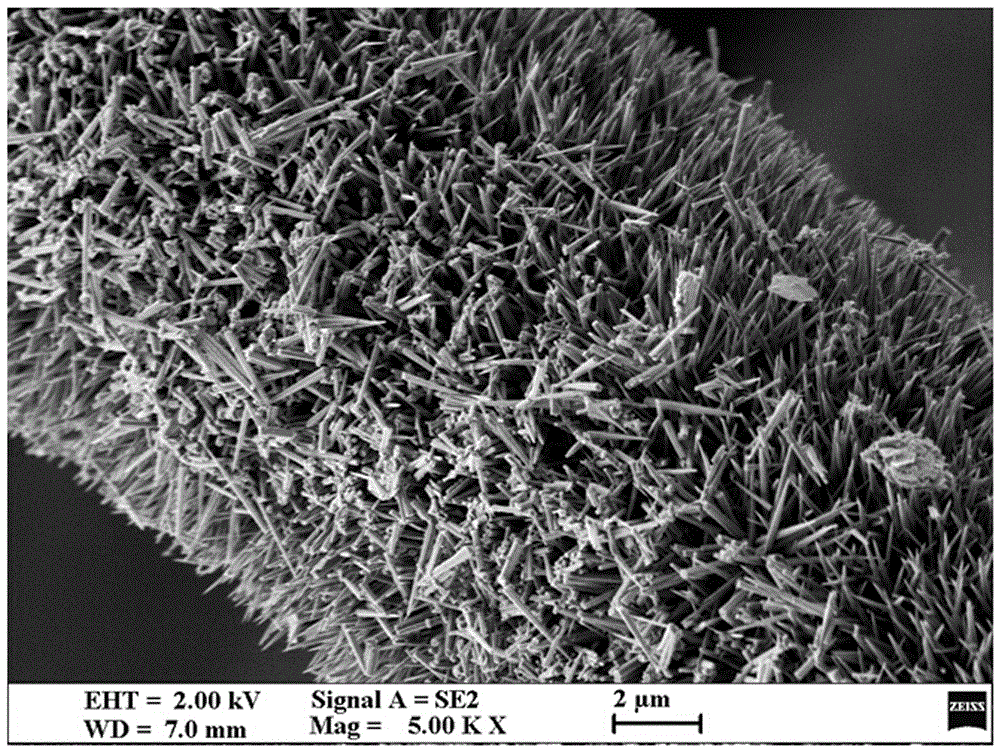

Preparation method and application of NiCo2S4/graphite felt composition electrode material

A composite electrode and graphite felt technology, applied in the field of nanomaterials and electrochemistry, can solve the problems of rare metal sulfide research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

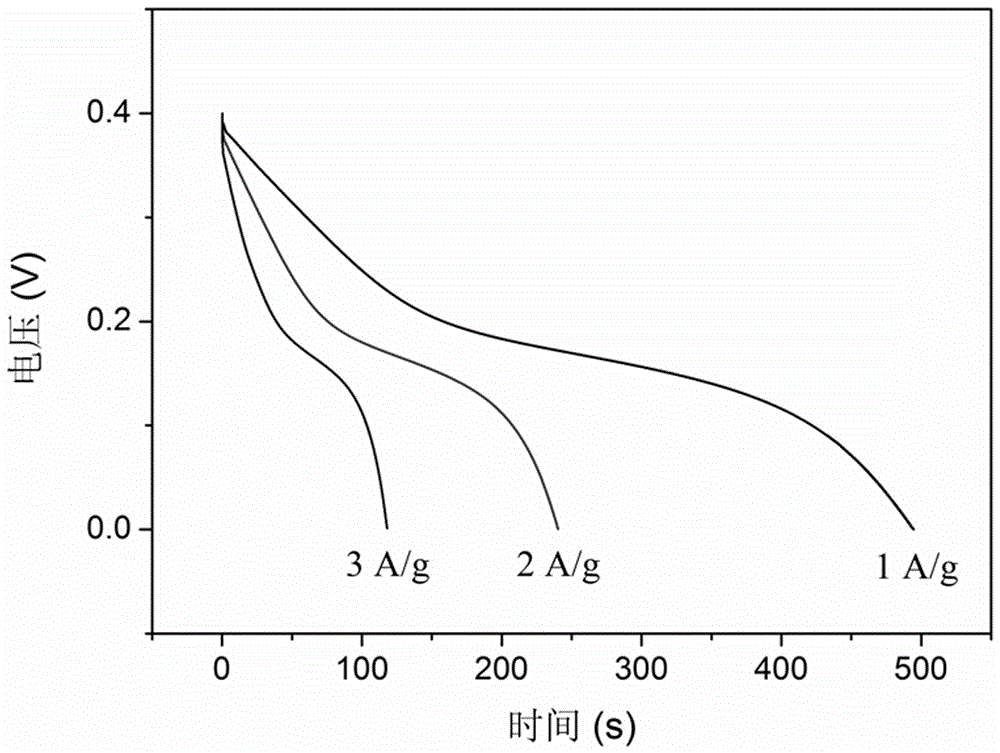

[0024] A kind of NiCo 2 S 4 / The preparation method of graphite felt composite electrode material, concrete process is as follows:

[0025] (1) Pre-oxidation treatment of graphite felt

[0026] The graphite felt was cut into a rectangle of 2 cm x 2 cm, ultrasonically cleaned with acetone, ethanol, and deionized water for 3 hours, and dried in vacuum at 60 °C for 24 h.

[0027] Prepare 40mL of aqua regia according to the volume ratio of concentrated hydrochloric acid and concentrated nitric acid 3:1, put the cleaned graphite felt into aqua regia, and oxidize at 80°C for 24h, and control the heating rate to 2°C / min. After natural cooling, the graphite felt was washed with deionized water until the pH was neutral, and dried at 60° C. to obtain a pretreated graphite felt.

[0028] (2) Loaded nickel-cobalt precursor

[0029] Configure 60ml mixed solution according to the volume ratio of deionized water and ethanol as 1:1, add nickel chloride and cobalt chloride in the ratio of ...

Embodiment 2

[0035] A kind of NiCo 2 S 4 / The preparation method of graphite felt composite electrode material, concrete process is as follows:

[0036] (1) Pre-oxidation treatment of graphite felt

[0037] The graphite felt was cut into a rectangle of 2 cm x 2 cm, ultrasonically cleaned with acetone, ethanol, and deionized water for 3 hours, and dried in vacuum at 60 °C for 24 h.

[0038] Prepare 40mL of aqua regia according to the volume ratio of concentrated hydrochloric acid and concentrated nitric acid 3:1, put the cleaned graphite felt into aqua regia, and oxidize at 80°C for 24h, and control the heating rate to 2°C / min. After natural cooling, the graphite felt was washed with deionized water until the pH was neutral, and dried at 60° C. to obtain a pretreated graphite felt.

[0039] (2) Loaded nickel-cobalt precursor

[0040]Configure 60ml mixed solution according to the volume ratio of deionized water and ethanol as 1:1, add nickel chloride and cobalt chloride in the ratio of 1...

Embodiment 3

[0046] A kind of NiCo 2 S 4 / The preparation method of graphite felt composite electrode material, concrete process is as follows:

[0047] (1) Pre-oxidation treatment of graphite felt

[0048] The graphite felt was cut into a rectangle of 2 cm x 2 cm, ultrasonically cleaned with acetone, ethanol, and deionized water for 3 hours, and dried in vacuum at 60 °C for 24 h.

[0049] Prepare 40mL of aqua regia according to the volume ratio of concentrated hydrochloric acid and concentrated nitric acid 3:1, put the cleaned graphite felt into aqua regia, and oxidize at 80°C for 24h, and control the heating rate to 2°C / min. After natural cooling, the graphite felt was washed with deionized water until the pH was neutral, and dried at 60° C. to obtain a pretreated graphite felt.

[0050] (2) Loaded nickel-cobalt precursor

[0051] Configure 60ml mixed solution according to the volume ratio of deionized water and ethanol as 1:1, add nickel chloride and cobalt chloride in the ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com