Air purification composite catalyst material and preparation method thereof

A composite catalyst and air purification technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of difficult-to-apply purification components for indoor and outdoor air, no multi-function, single purification and degradation of harmful gases and other problems, to achieve excellent catalytic performance, good purification effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

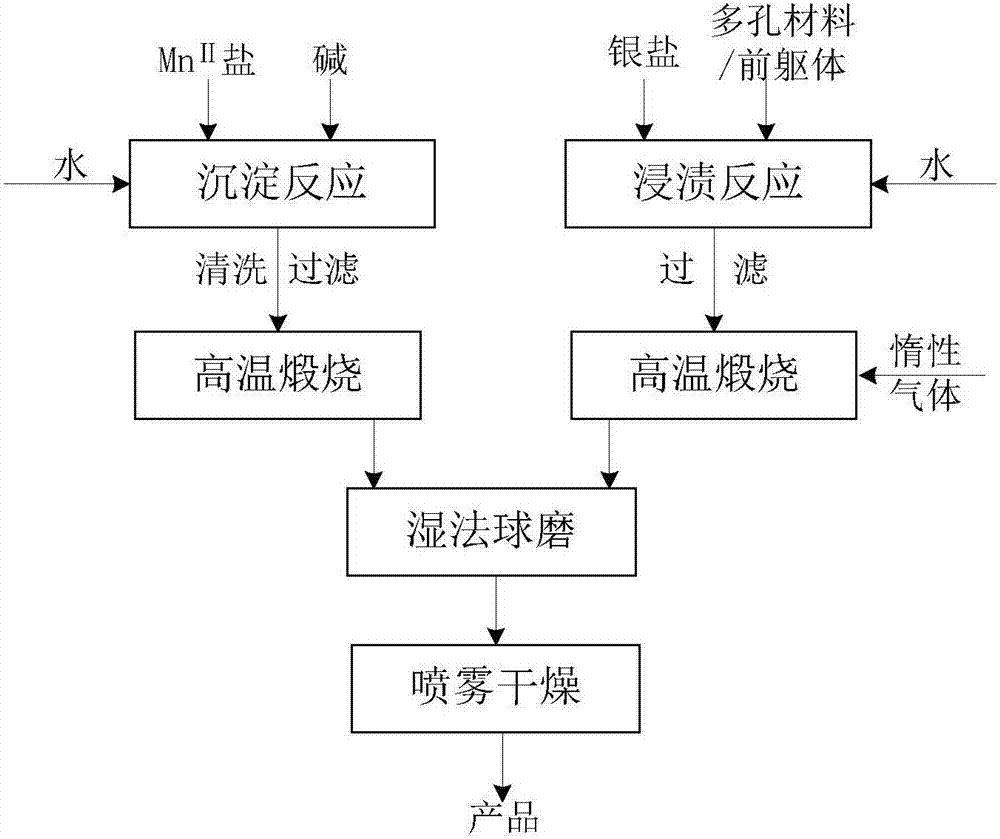

Method used

Image

Examples

Embodiment 1

[0040] Add 15.8g of potassium permanganate and 22.3g of manganese sulfate tetrahydrate in sequence to 305g of pure water, stir well until completely dissolved, react at 95°C for 1 hour, then transfer the solution to a closed reaction kettle at 100°C and 2 MPa After reacting for 20 hours, take it out, wash it, and filter to obtain the catalyst filter residue for use. The dried coconut shell of 41.4g (according to reports, the carbon content of dry coconut shell is 21%) is broken and immersed in the silver nitrate solution of 500mL5mol / L, takes out after soaking 30h under the condition of 0 ℃, puts into In a high-temperature furnace at 440°C, under the protection of a nitrogen (0.2 L / min) atmosphere, the activated carbon with silver was obtained by calcining for 20 hours. Mix the manganese dioxide catalyst filter residue prepared above with silver-attached biomass activated carbon and add 32.6g of water, then put it into a ball mill, add 1mm zirconia balls and ball mill for 10h ...

Embodiment 2

[0043] Add 14.2g of sodium permanganate and 14.35g of manganese sulfate hexahydrate in sequence to 571g of pure water, stir well until completely dissolved, react at 50°C for 10h, and then transfer the solution to a closed reaction kettle at 150°C and 1.5 MPa After reacting for 10 hours, take it out, wash it, and filter to obtain the catalyst filter residue for use. Immerse 47.2g of porous silica powder into 500mL of 3mol / L silver sulfate solution, take it out after immersion at 50°C for 12h, put it into a high-temperature furnace at 800°C, The silver-attached porous silica material was obtained after calcining for 6 hours under the protection of atmosphere. Mix the manganese dioxide catalyst filter residue prepared above with silver-coated porous silica and add 413.3g of water, then put it into a ball mill, add 5mm zirconia balls and ball mill for 1h under the condition of 1000r / min to obtain a solid The content is 5% of the mixed suspension; then the above suspension is dri...

Embodiment 3

[0046] Add 22.05g of lithium permanganate and 9.9g of manganese chloride tetrahydrate in turn to 1600g of pure water, stir well until completely dissolved, react at 0°C for 30h, and then transfer the solution to a closed reaction kettle at 200°C and 0.5 MPa After 1 hour of reaction in the middle, take it out, wash it, and filter to obtain the catalyst filter residue for later use. Immerse 80.24g of porous alumina into 500mL of 1mol / L silver sulfate solution, take it out after immersing at 70°C for 6h, put it into a high-temperature furnace at 1200°C, and protect it under the atmosphere of helium (gas flow of 3L / min) After calcining for 1 hour, a silver-attached porous alumina material was obtained. Mix the above-prepared manganese dioxide catalyst filter residue with silver-coated porous alumina and add 110.7g of water, then put it into a ball mill, add 3mm zirconia balls and ball mill for 15 hours under the condition of 1200r / min to obtain the solid content It is a 20% mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com