Preparation method of flue gas desulfurization and denitrification absorbent for rice hull ash/carbide slag system

A desulfurization and denitrification, calcium carbide slag technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problem that the denitrification efficiency is less than 40%, achieve large specific surface area, improve denitrification efficiency, and improve desulfurization activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

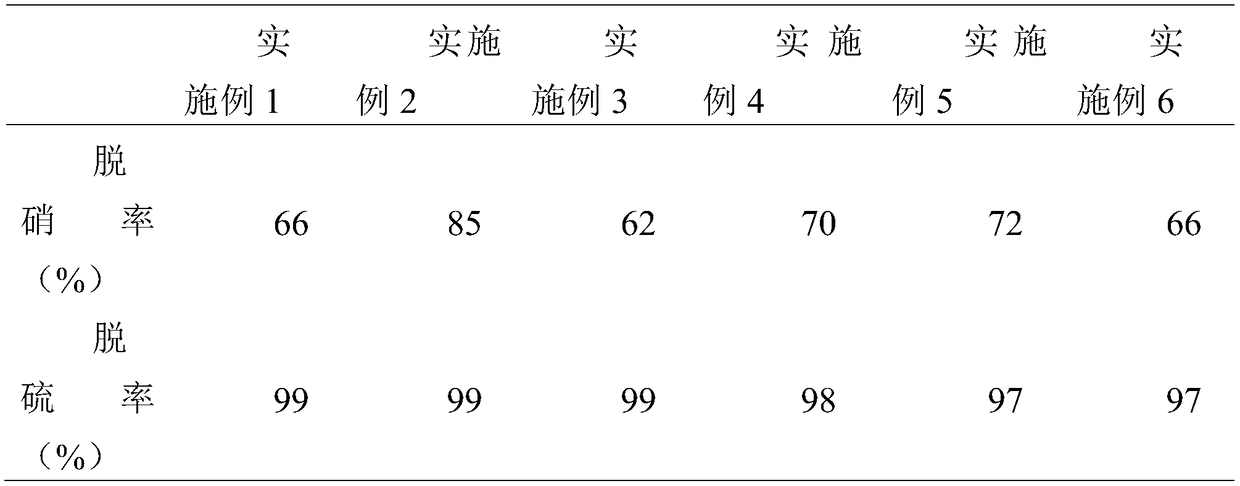

[0019] Heat 100mL of deionized water to 70°C and put in 5g of calcium carbide slag, while stirring continuously, heat up to 85°C after mixing evenly, and add 5g of rice husk ash into the slurry, stir evenly, heat up to 100°C, and heat at constant temperature for 11 hours And keep magnetic stirring at 300r / min, filter the obtained slurry and dry at 150°C for 2h, and grind the dry powder. The absorbent of the rice husk ash / calcium carbide slag system was mixed with 90% cement raw meal at a mass ratio of 10%. Under simulated flue gas conditions, a simultaneous desulfurization and denitrification test was carried out. The denitrification rate reached 66% at 700°C, and the desulfurization The rate reaches 99%.

Embodiment 2

[0021] Heat 200mL of deionized water to 70°C and put in 5g of calcium carbide slag, while stirring continuously, mix evenly and then raise the temperature to 85°C, and add 5g of rice husk ash to the slurry, stir evenly, raise the temperature to 130°C, and heat at constant temperature for 8h And keep magnetic stirring at 300r / min, filter the obtained slurry and dry at 150°C for 2h, and grind the dry powder. The absorbent of the rice husk ash / calcium carbide slag system was mixed with 90% cement raw meal at a mass ratio of 10%. Under simulated flue gas conditions, a simultaneous desulfurization and denitrification test was carried out. The denitrification rate reached 85% at 700°C, and the desulfurization The rate reaches 99%.

Embodiment 3

[0023] Heat 50mL of deionized water to 60°C, put in 5g of carbide slag, stir continuously, mix well, then heat up to 70°C, add 5g of rice husk ash to the slurry, heat at 70°C for 5h and keep at 300r / min The obtained slurry was filtered and dried at 150° C. for 2 h, and the dry powder was ground. The absorbent of the rice husk ash / carbide slag system was mixed with 90% cement raw meal at a mass ratio of 10%. Under simulated flue gas conditions, a simultaneous desulfurization and denitrification test was carried out. The denitrification rate reached 62% at 700°C, and the desulfurization The rate reaches 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com