Composite Circulation fluidized dry desulfurization process for flue gas and desalfurizing reaction tower

A technology of dry flue gas desulfurization and combined cycle, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, which can solve the problems of reducing the effective space utilization rate of the reaction tower, poor surface activity of desulfurizing agent particles, and clean flue gas carryover. Problems such as excessive water volume, to achieve the effect of improving space utilization, prolonging space and time, and reducing water consumption requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

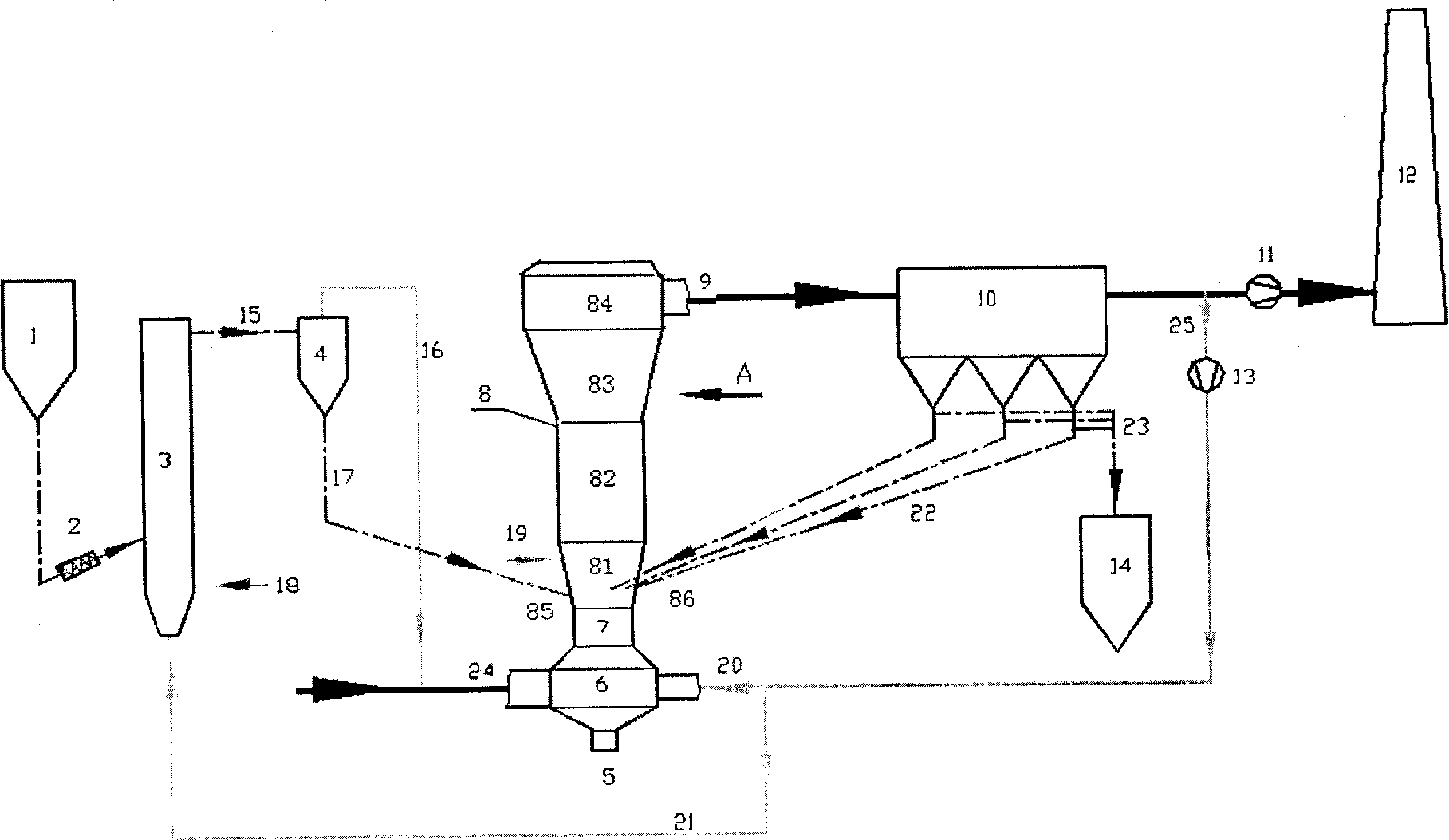

[0026] First, the present invention simultaneously adopts three recycling methods to form a composite circulating fluidized desulfurization system:

[0027]1) Recirculation technology of desulfurizer particles in the desulfurization reaction tower is adopted.

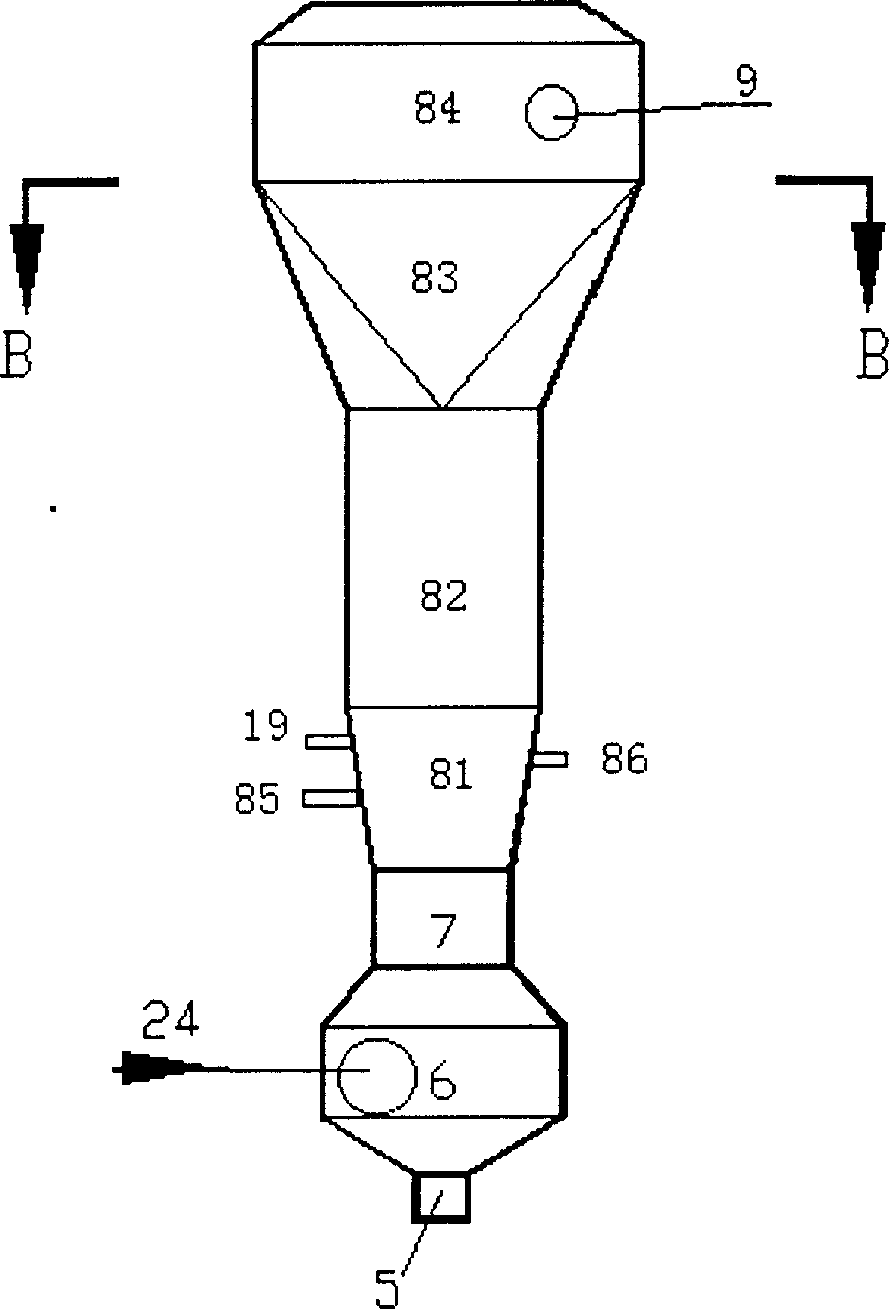

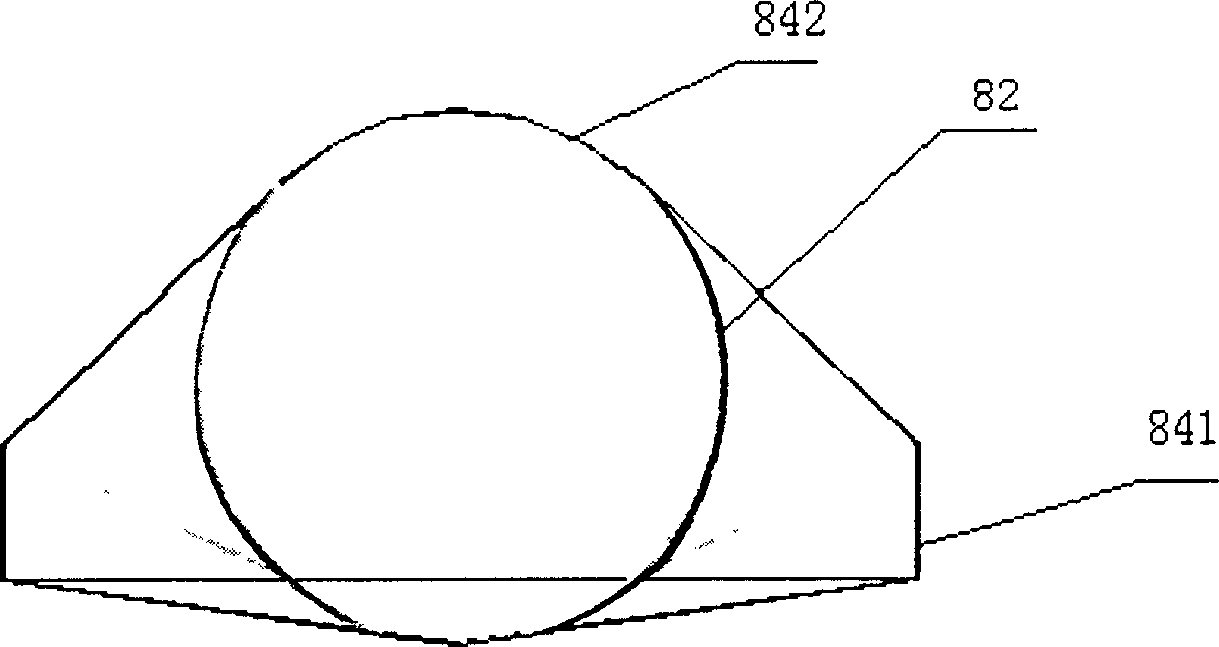

[0028] This technology strengthens the internal circulation characteristics of the particles in the desulfurization reaction tower 8. Through a variety of layout and variable cross-section desulfurization tower design, the flow rate of flue gas in the tower changes step by step along with its rising process. On the one hand, it can reduce and adjust the particle drag force at the top of the absorption tower, and on the other hand, on the inner wall of the tower A local vortex zone is formed at the mutation point, which strengthens the internal circulation of the desulfurizing agent particles in the tower, and the internal circulation of the particles can reach between 40% and 80%. In the case of reducing the abrasion of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com