Liquid phase reaction vessel with uniform reaction function

A container-response and uniform technology, applied in the field of liquid-phase reaction vessels, can solve the problems of poor uniformity of material composition and temperature, and achieve the effects of uniform material composition and temperature, ensuring uniformity and uniformity of temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

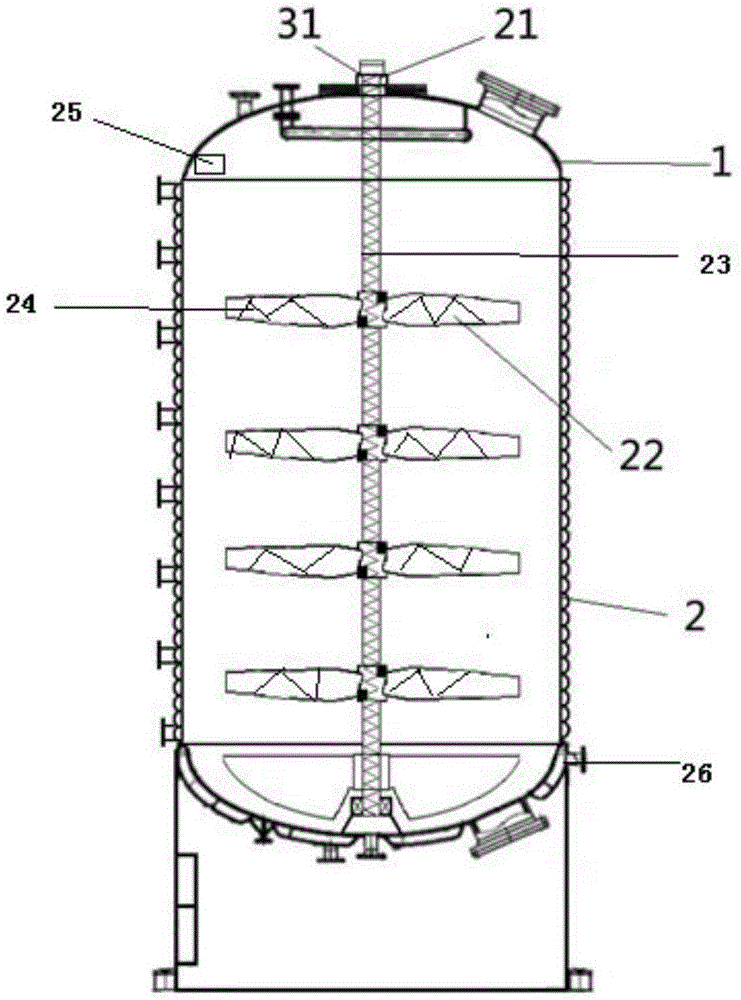

[0039] This embodiment provides a liquid phase reaction vessel, such as figure 1 ,include,

[0040] The tank body 1 has an accommodating space;

[0041] An external heating device is arranged around the outer wall of the tank body 1;

[0042] Stirring device, including the rotating shaft 21 that is arranged in the central position of the tank body 1 along the vertical direction and can be driven by the power device to rotate, and a number of paddles 22 arranged on the rotating shaft 21, the rotating shaft 21 and the paddles 22 are made of heat-conducting materials, and both the rotating shaft 21 and the paddle 22 have cavities;

[0043] The internal heating device includes a first heating wire 23 insulated in the cavity of the rotating shaft 21 and a second heating wire 24 insulated in the cavity of the paddle 22, which can generate heat when energized, through Control the electric control button 31 to control the first heating wire 23 to energize and generate heat;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com