Processing method of waste nitric acid fume and device thereof

A treatment method and exhaust gas technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as difficult and complete reactions, large gas and liquid, low fan energy consumption, etc., to increase reaction space and time, and equipment The effect of simple structure and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

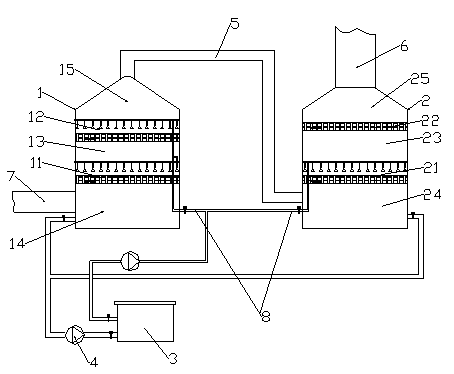

[0017] A treatment method for nitric acid mist waste gas, comprising the following steps:

[0018] 1) Introduce the nitric acid mist waste gas into a main absorption tower, and at the same time, the first comprehensive reaction occurs between the nitric acid mist waste gas and the medicament introduced into the main absorption tower. The movement direction of the nitric acid mist exhaust gas is sprayed against the opposite direction, and in the first comprehensive reaction, the packing layer is used to slow down the exhaust gas and make the spraying agent evenly distributed and fully reacted;

[0019] 2) A hollow layer is set in the main absorption tower to decelerate the exhaust gas, increase the reaction space and time, and prevent the exhaust gas from turbulent flow. After the first comprehensive reaction, the nitric acid mist exhaust gas passes through the hollow layer without installing spray equipment and the packing layer, and then have a second comprehensive reaction w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com