Low-temperature plasma generating device

A technology of low-temperature plasma and generating device, applied in the direction of plasma, electrical components, etc., can solve the problems of poor corona discharge safety, and achieve the effect of increasing the reaction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

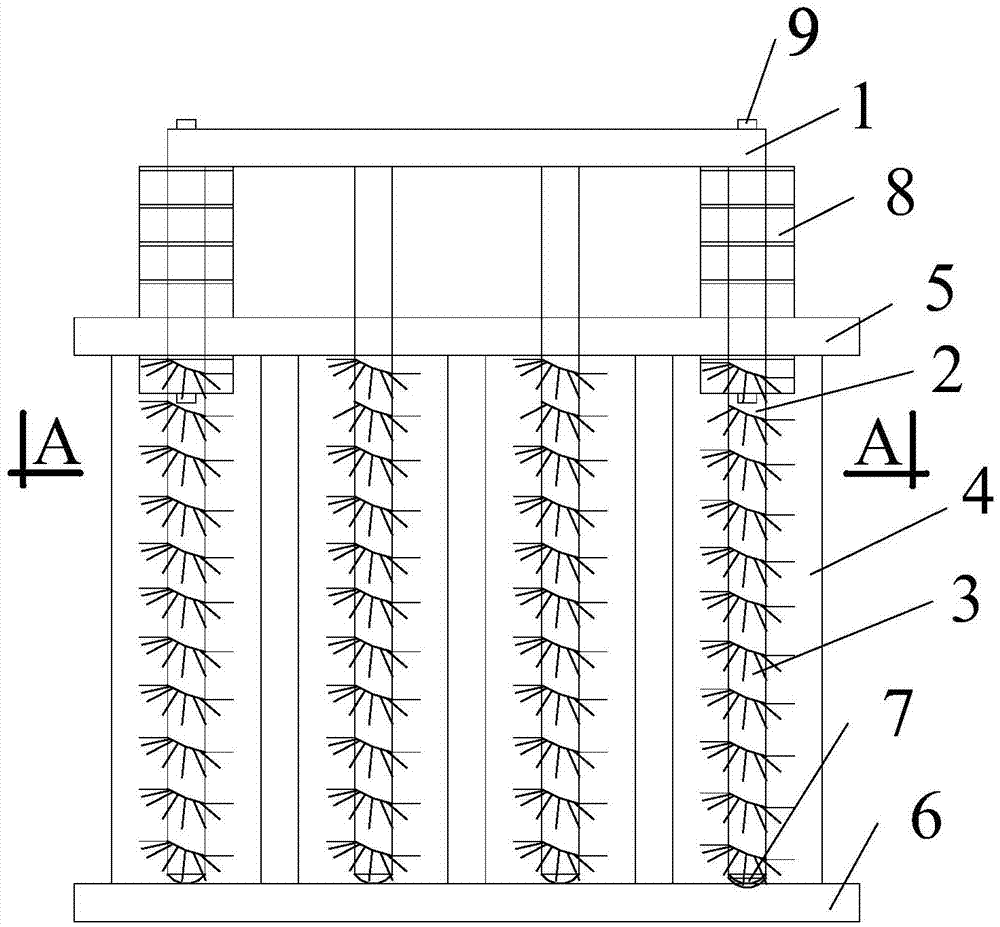

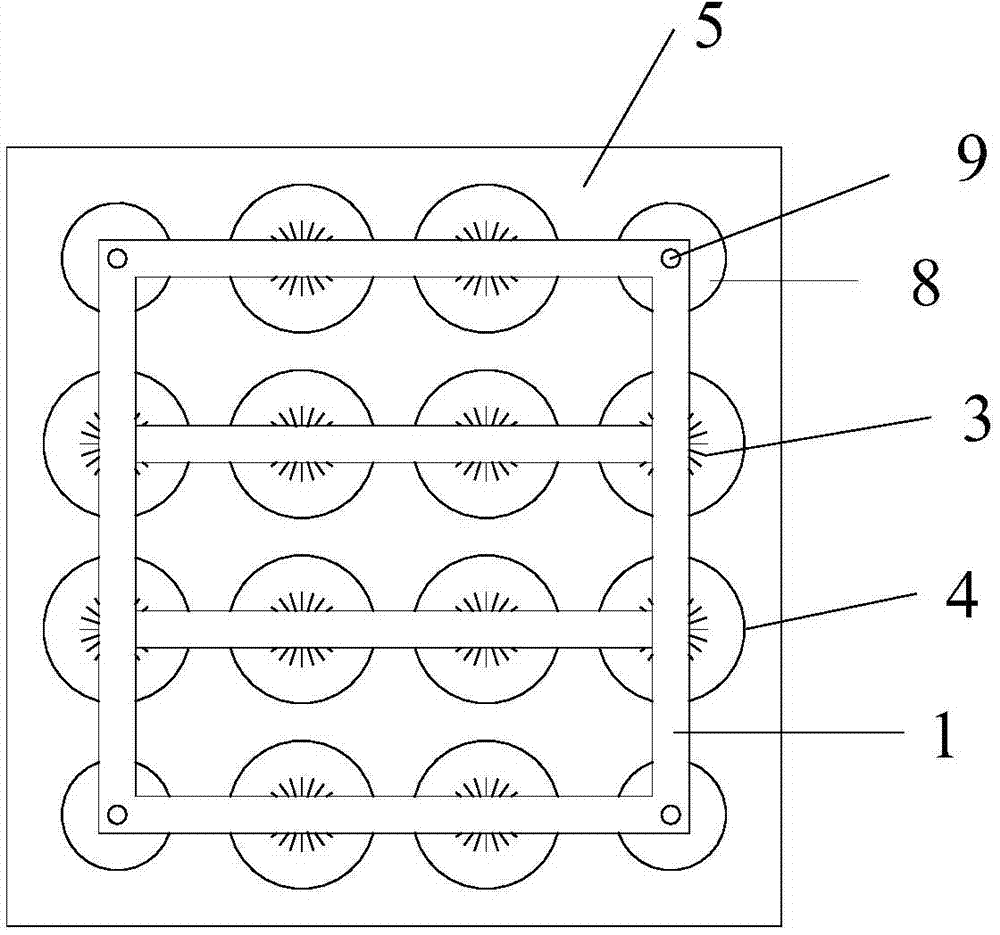

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] The low-temperature plasma generating device in the present invention includes a reactor and a power supply; the reactor includes a corotron support 1, an insulator 8, an upper baffle 5, a plasma reaction chamber and a lower baffle 6 connected in sequence, and the plasma There are n reaction chambers arranged in parallel, and n is a natural number greater than 2;

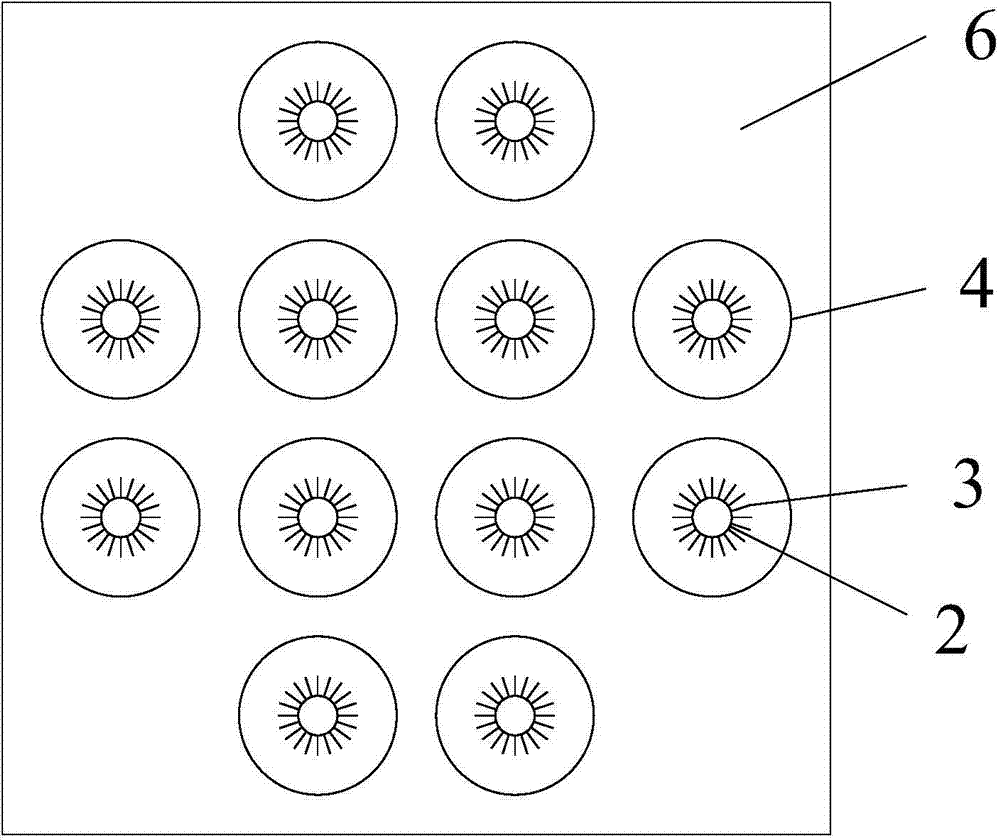

[0034] The plasma reaction chamber includes a corona tube 2 and a reaction chamber shell 4, both of which are made of corrosion-resistant metal; the reaction chamber shell 4 is in the shape of a hollow cylinder, the outer edge of the upper end is seamlessly connected with the upper baffle plate 5, and the outer edge of the lower end is connected with the lower The baffle plate 6 is seamlessly connected;

[0035] The corona tube 2 is coaxial with the reaction chamber shell 4, and the cavity between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com