Wooden club head

a wood-based club head and golf club technology, applied in the field of golf clubs, can solve the problems of adversely affecting the sound quality, low assembling tolerance, high manufacturing cost, etc., and achieve the effect of increasing the volume of the overall club head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

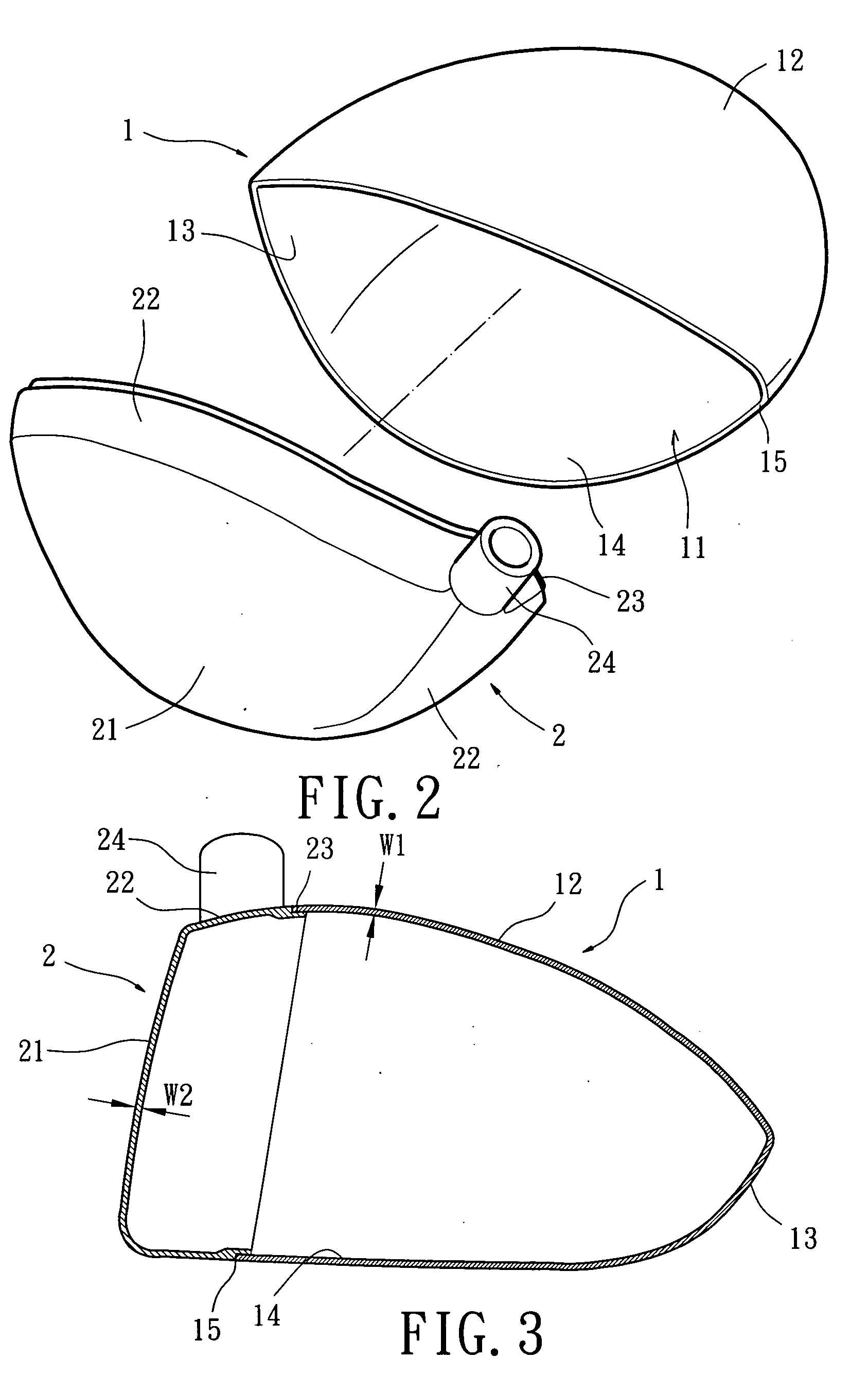

[0018]Referring to FIGS. 2 and 3, a wooden club head of a first embodiment in accordance with the present invention includes a thin body component 1 and a thin faceplate component 2 coupled to a front side of the thin body component 1 to form a two-piece type golf club head. The thin body component 1 and the thin faceplate component 2 are made of steel alloy such as stainless steel (e.g., 17-4PH stainless steel), martensite steel, carbon steel, low-carbon steel, alloy steel, low-alloy steel, structural steel, super alloy steel or a combination thereof. The thickness W1 of the thin body component 1 is preferably between 0.25 mm and 0.8 mm. The thickness W2 of the thin faceplate component 2 is preferably between 1.5 mm and 3.0 mm.

[0019]The thin body component 1 includes a front engaging opening 11, a crown 12, a sidewall 13, a sole 14, and a front abutting face 15. The front engaging opening 11 is formed on the front side of the thin body component 1 for coupling with the thin facepla...

second embodiment

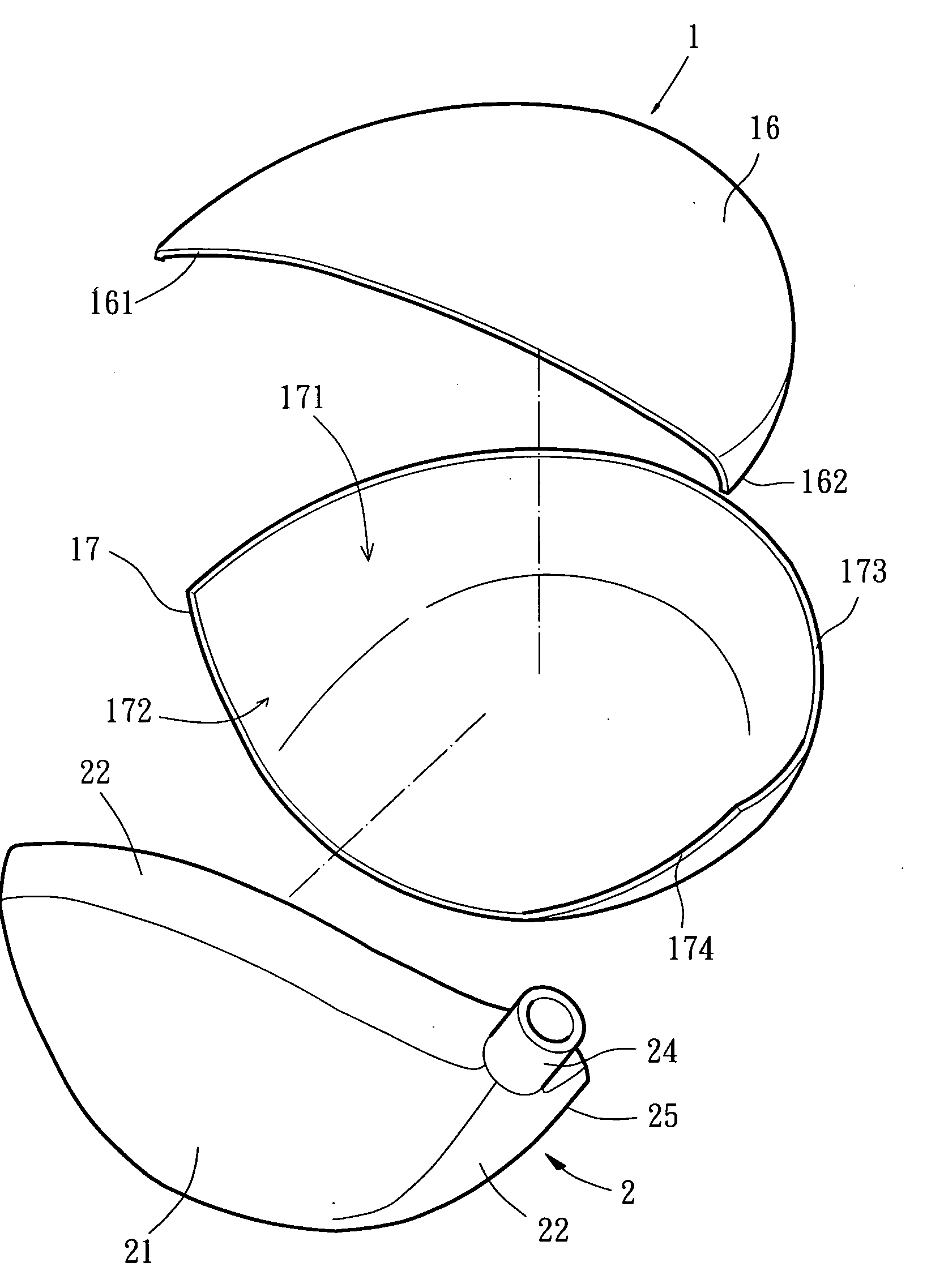

[0022]FIGS. 4 and 5 show a wooden club head of the present invention. Compared to the first embodiment, the thin body component 1 of the second embodiment is comprised of a thin crown component 16 and a thin sole component 17. The thin crown component 16 is coupled to a top side of the thin sole component 17 and forming the crown 12, which is shown in FIG. 1, of the thin body component 1. And the thin sole component 17 below the thin crown component 16 forms the sidewall 13 and the sole 14, which are also shown in FIG. 1, of the thin body component 1. Furthermore, the thin crown component 16 includes a front engaging face 161 and a coupling skirt 162. The front engaging face 161 is formed on a front edge of the thin crown component 16, and the coupling skirt 162 extends along a bottom edge of the thin crown component 16. Further, the thin faceplate component 2 in the second embodiment has no stepped portion 23 but has a rear coupling face 25.

[0023]The thin sole component 17 includes...

third embodiment

[0025]FIGS. 6 and 7 show a wooden club head of the present invention. Compared to the second embodiment, most part of the bend 22 of the thin faceplate component 2 is omitted in the third embodiment. In particular, only a portion of the bend 22 adjacent to the neck 24 is kept to reinforce the structural strength of the neck 24. Furthermore, the thin crown component 16 includes an opening 163 on a side corresponding to the neck24 of the thin faceplate component 2 for receiving the neck 24 when the thin faceplate component 2 is coupled with the thin body component 1. Thus, the overall volume of the golf club head can be increased under the preset overall weight limitation while the assembling tolerances of the golf club head is increased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com