Preparation method of tritium multiplication ceramic pellet in fusion reactor solid blanket

A technology for tritium breeding and fusion reactors, which is applied in fusion reactors, thermonuclear fusion reactors, nuclear reactors, etc., can solve the problems of high technological requirements for small spheroid transfer technology, high porosity of small spherules, and difficulty in large-scale production. Achieve the effect of easy industrial production, uniform particle size and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

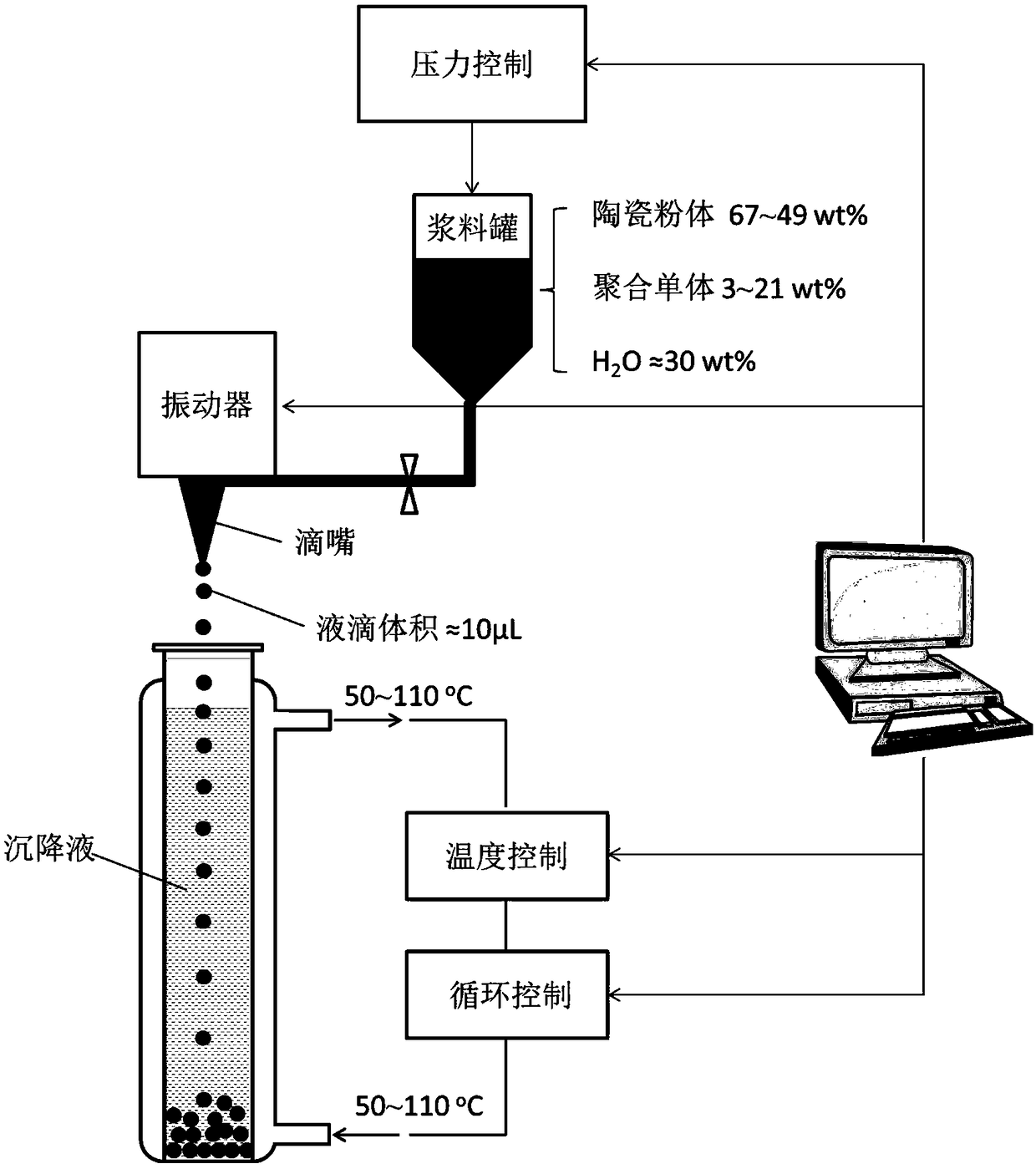

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0028] 1. Raw material preparation.

[0029] Propagate ceramic powder with micron lithium oxide tritium (including Li 2 TiO 3 , Li 4 SiO 4 , Li 2 be 2 o 3 , LiAlO 2 and Li 8 ZrO 6 ) as the raw material, and the raw material is passed through a 200-mesh sieve after ball milling, so that the particle size of the powder is less than 100 μm.

[0030] 2. Slurry preparation.

[0031] The ceramic powder, deionized water and organic monomers were evenly mixed, and ball milled at a rate of 1000 rpm for 2 hours to prepare a ceramic slurry. The added organic monomers that can undergo polymerization reactions include one or more of acrylamide, N,N-methylenebisacrylamide, acrylate, polyvinyl alcohol, citric acid, ethylene glycol, glycerol, etc., The addition amount is 5-30% of the mass of the ceramic powder.

[0032] 3. Settling polymerization....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com