Opening type micro-fluidic chip, as well as manufacture method and operation method of micro-fluidic chip

A microfluidic chip and manufacturing method technology, applied in the field of microfluidics, can solve the problems of high manufacturing cost, difficult operation, difficult large area, patterned super-smooth surface preparation, etc., to reduce the difficulty and cost of preparation, and not easy to damage Failure, the effect of reducing viscous resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

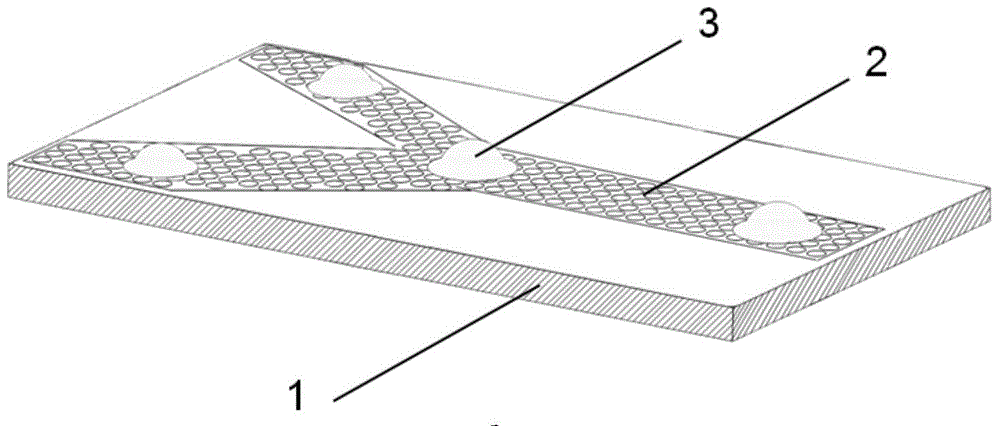

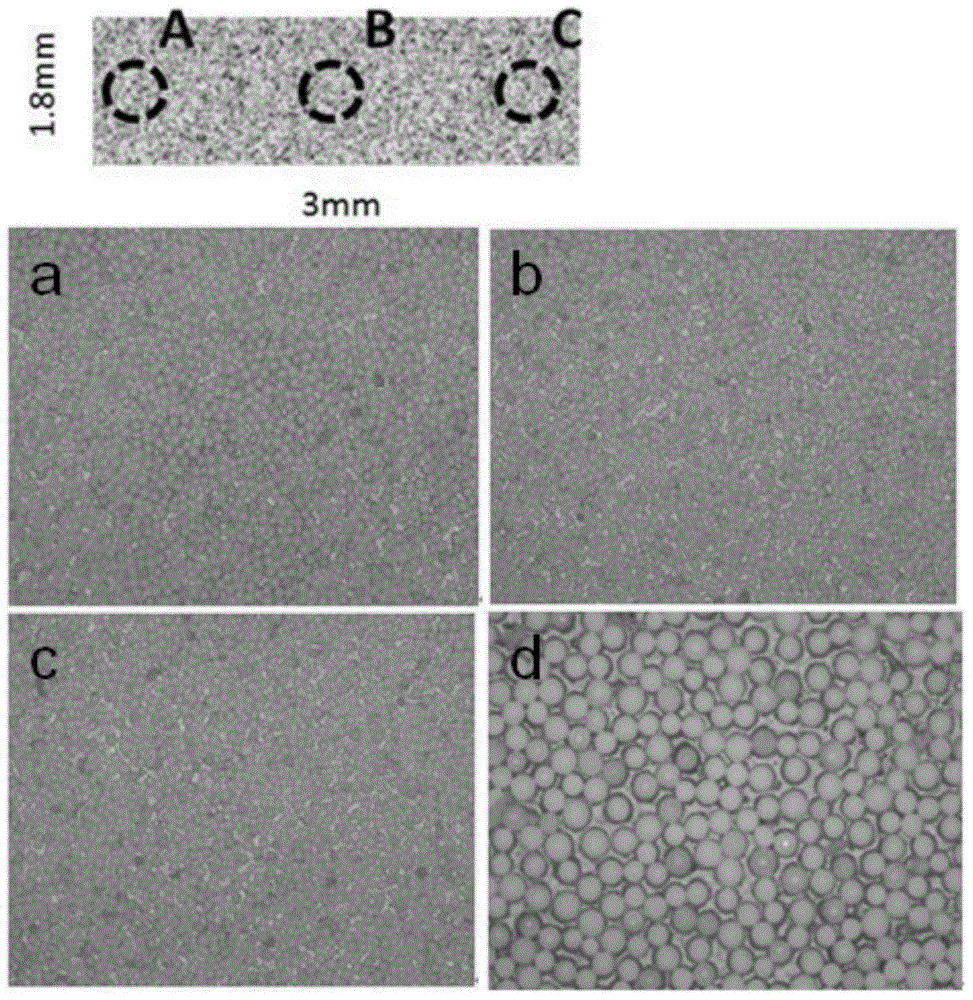

[0069] In this example, an adhesive layer is first formed by coating a viscous substance, and then a microsphere template is formed by a splashing method, and then the microsphere template is patterned and cut, and then the patterned template is softly copied and transferred using PDMS to obtain a concave microsphere. Finally, lubricating oil is filled into the concave microstructure to obtain a super-smooth surface, and a planar microfluidic chip is made.

[0070] The method for making the super-slippery surface in this embodiment specifically includes the following steps:

[0071] (a) Apply a layer of glue evenly on the substrate, and the thickness of the glue should be uniform to avoid uneven surface of the formed adhesive layer.

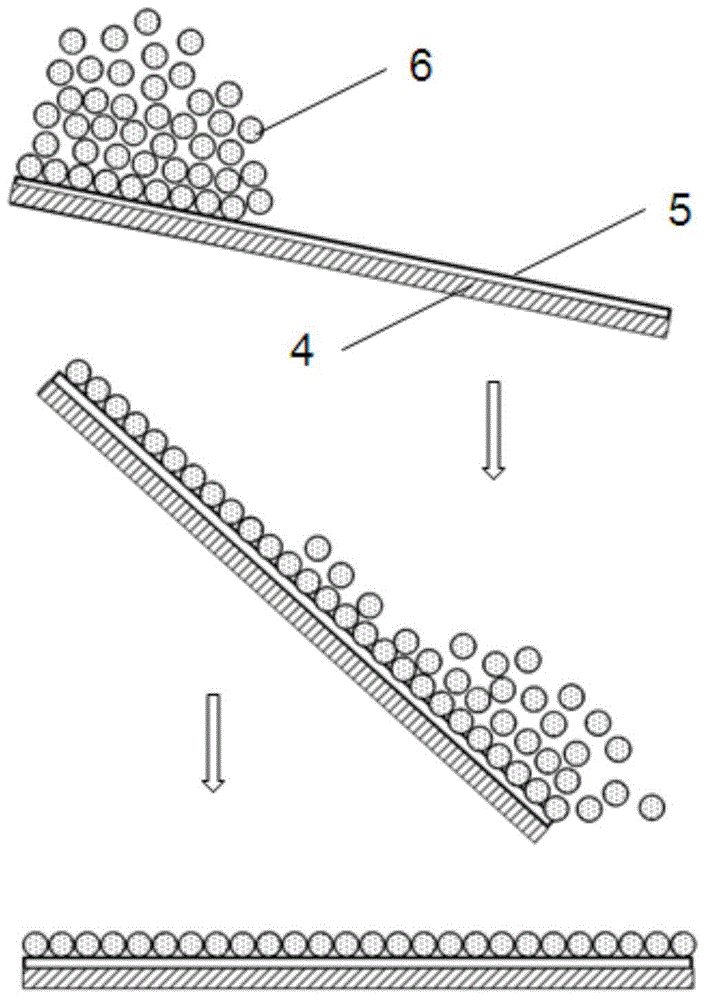

[0072] (b) in accordance with figure 2 In the manner shown, a large number of PS microspheres are evenly sprinkled on the surface of the adhesive layer of the substrate in step (a), the substrate is tilted and the unadhered microspheres are rem...

Embodiment 2

[0078] The difference between this embodiment and Embodiment 1 is that this embodiment forms an adhesive layer by pasting double-sided adhesive tape on the substrate, and other steps are the same as Embodiment 1.

Embodiment 3

[0080] The difference between this embodiment and Embodiment 1 is that this embodiment uses a printer to print viscous substances (glue) on the substrate to form a patterned adhesive layer; Form a single-layer microsphere template; then use PDMS to perform soft replication on the single-layer microsphere template; finally, fill the lubricating oil in the concave microstructure formed by soft replication to form a lubricating oil film, obtain a super-smooth surface, and make a planar microfluidic device. chip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com