Patents

Literature

44results about How to "Ensure braking stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

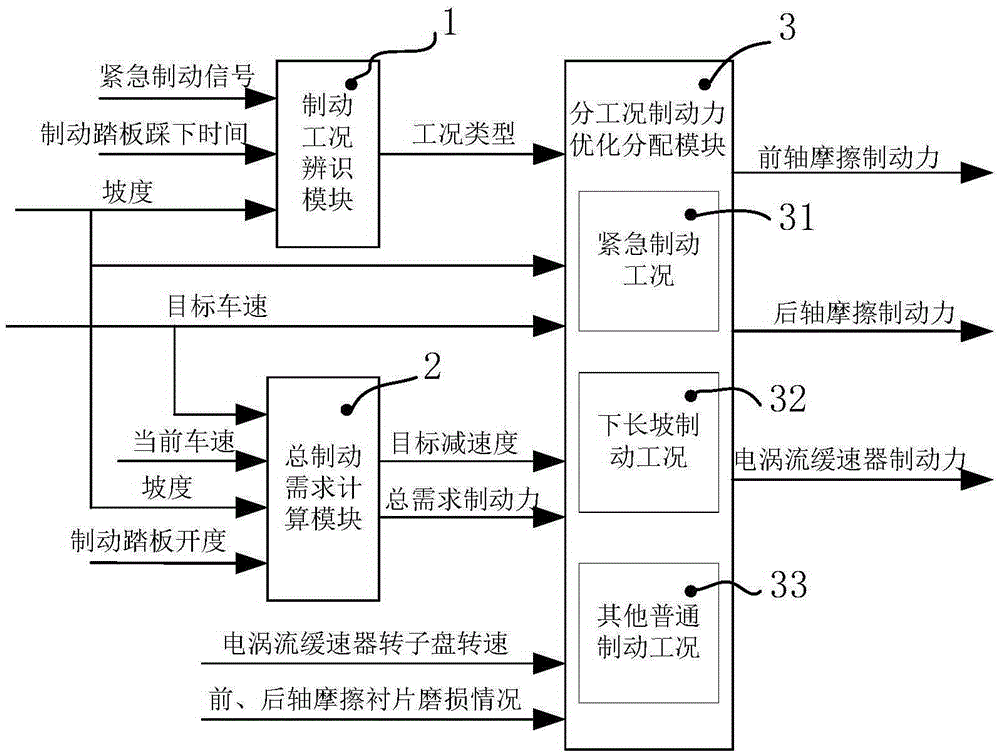

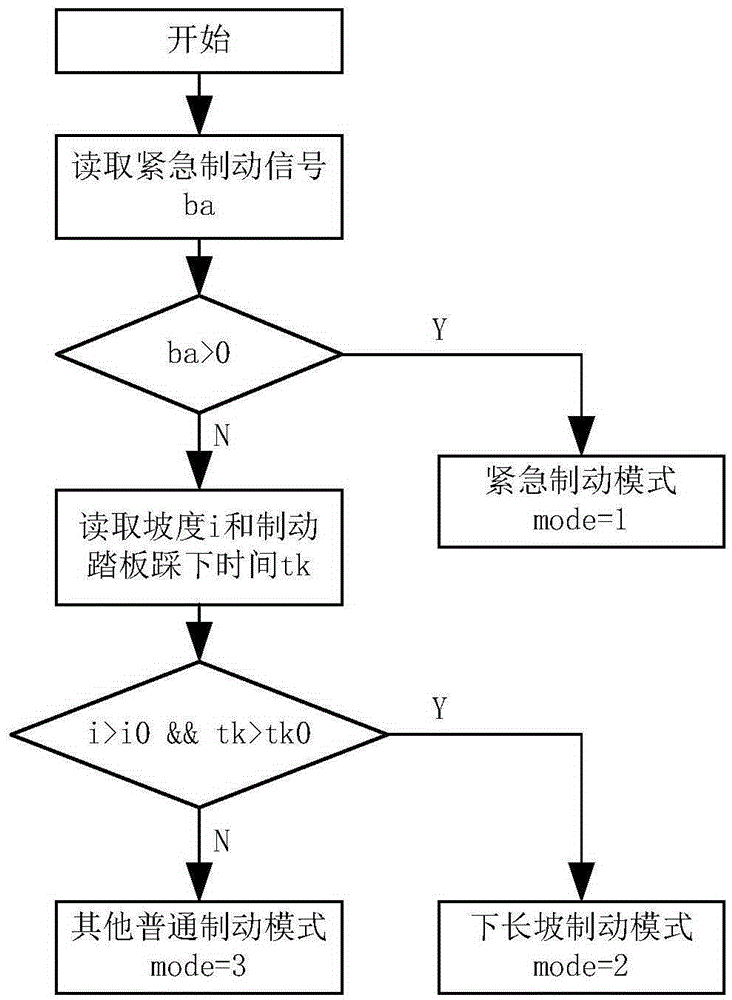

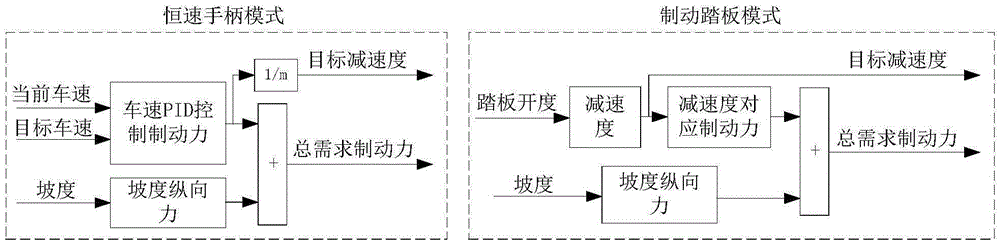

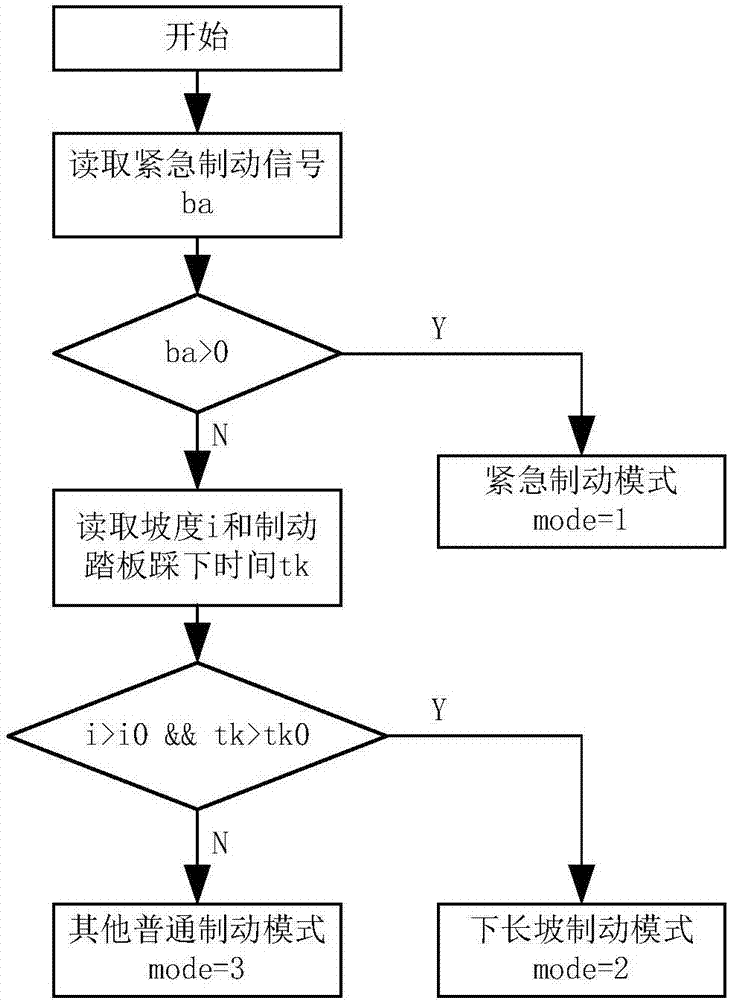

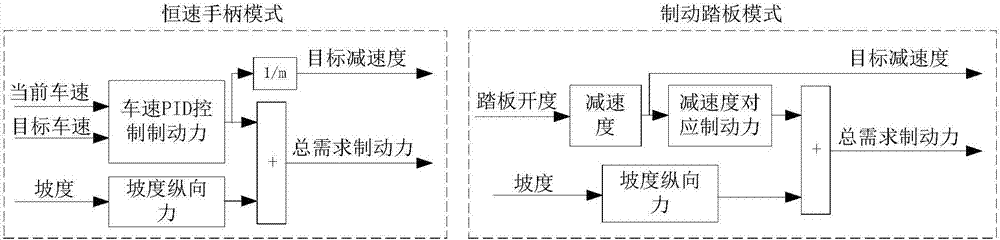

Method for optimizing braking force distribution of integrated braking system of commercial vehicle according to working conditions

InactiveCN105292092AQuick responseReduces and equalizes wearBraking action transmissionElectrodynamic brake systemsEddy currentEngineering

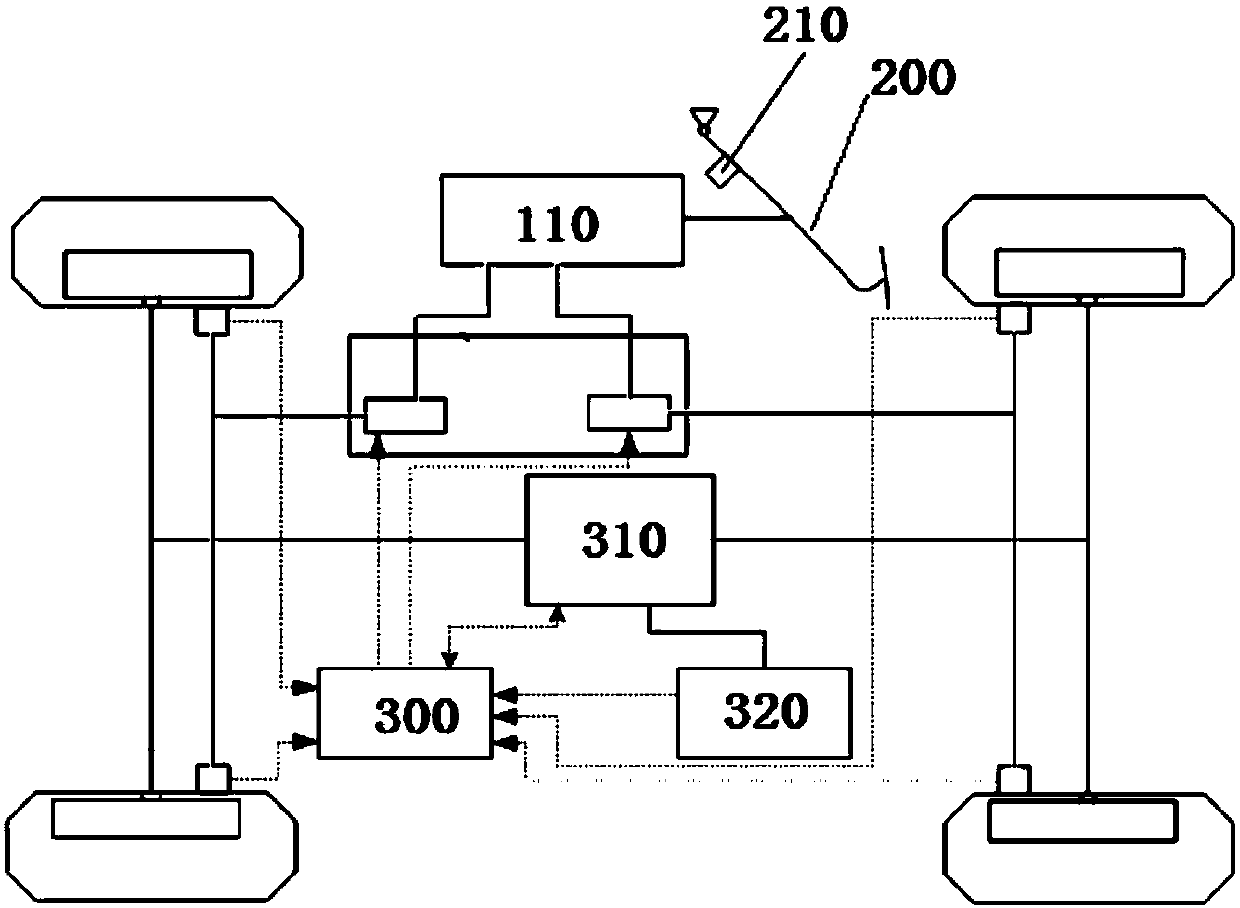

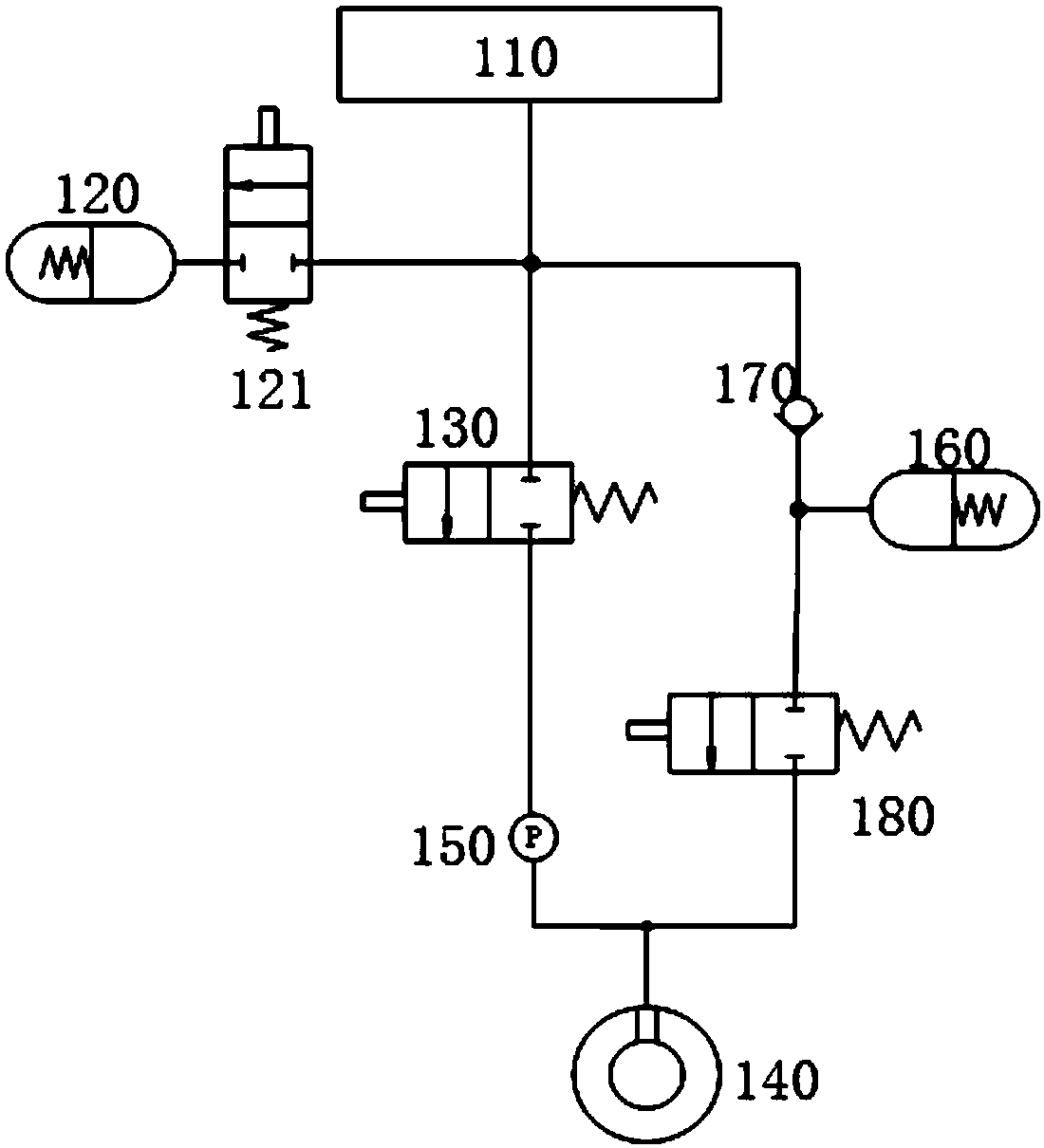

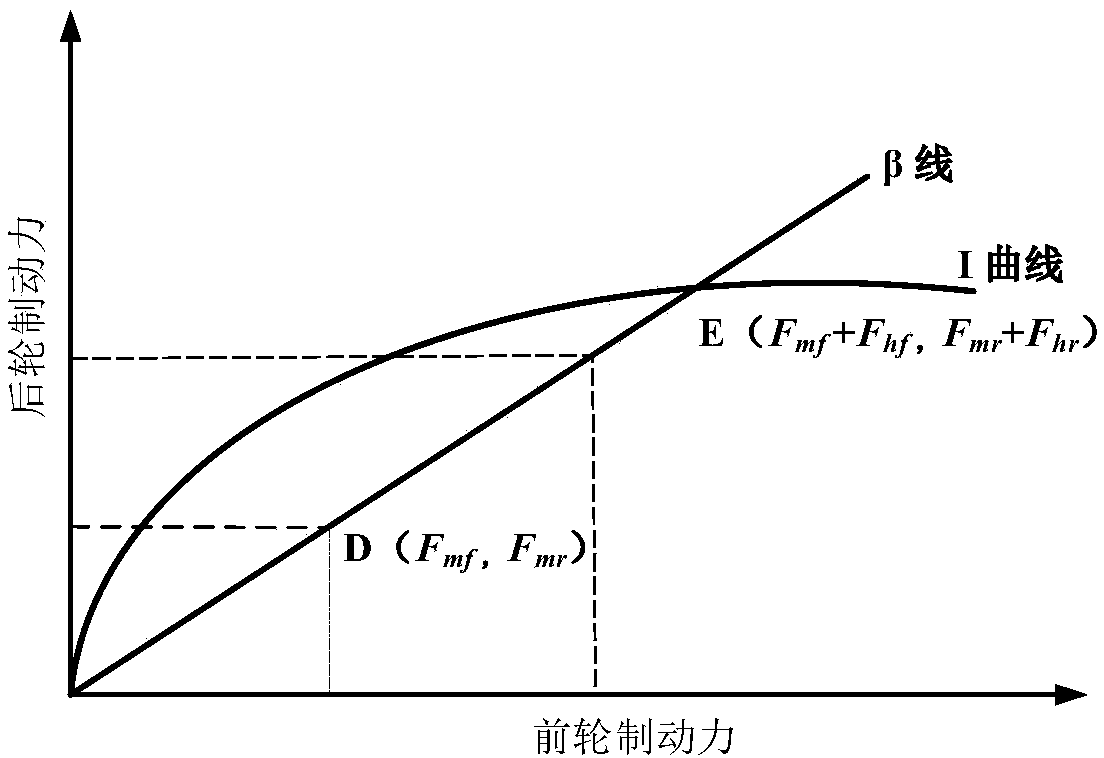

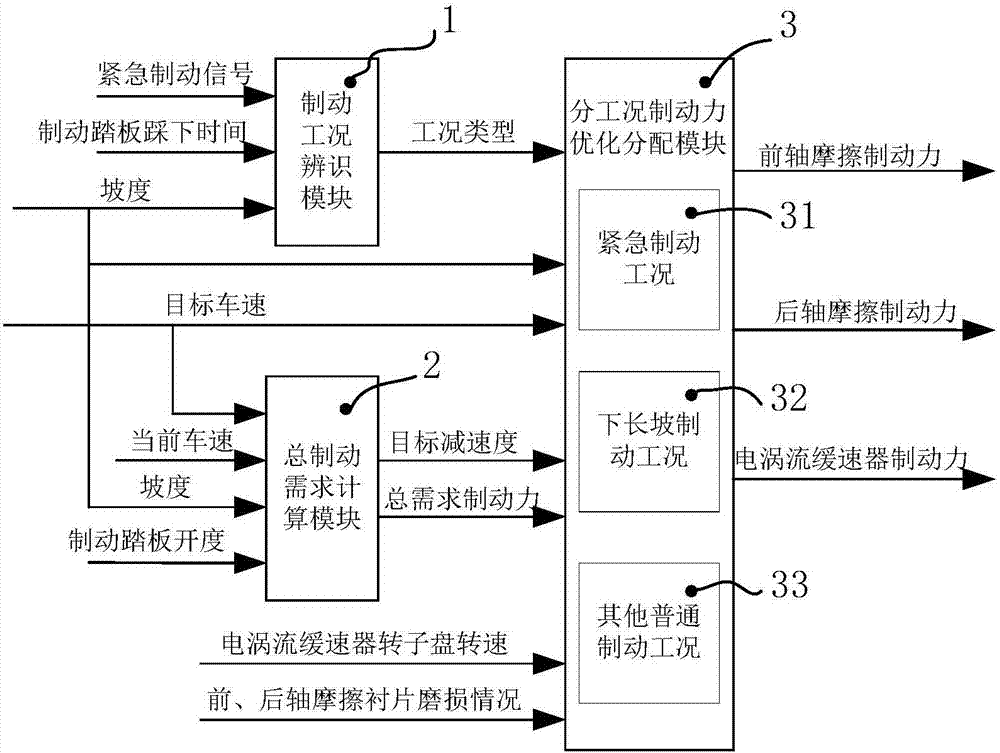

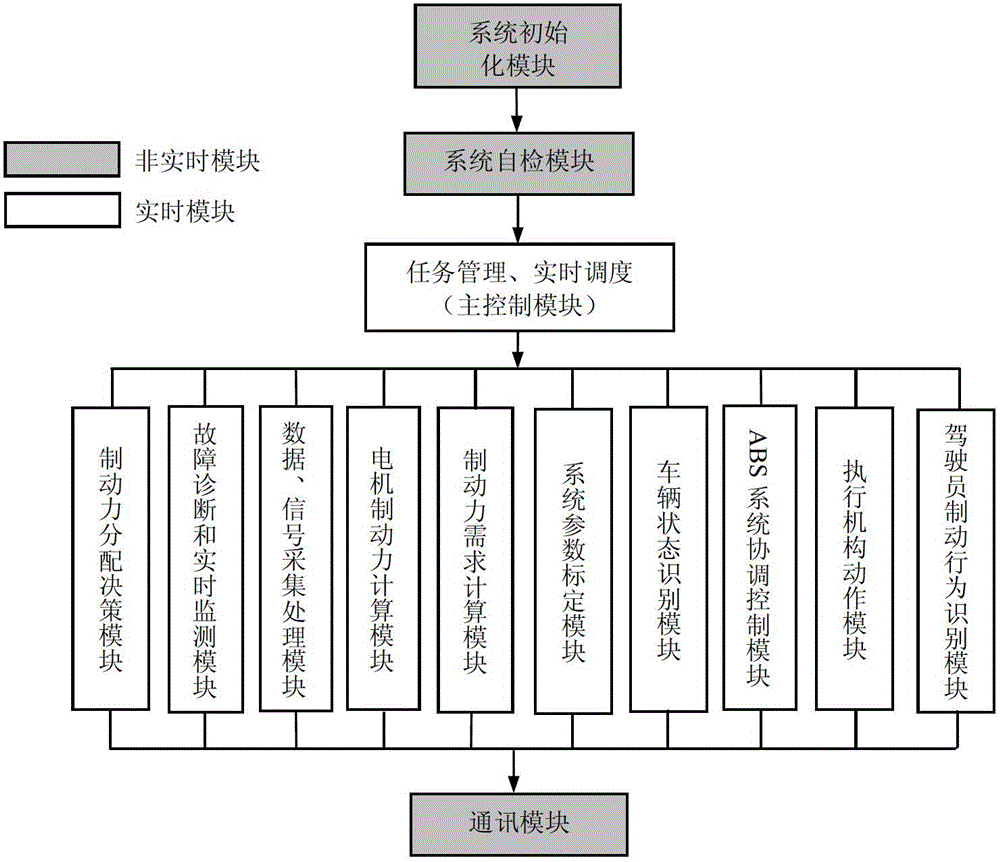

Disclosed is a method for optimizing braking force distribution of an integrated braking system of a commercial vehicle according to working conditions. The method for optimizing braking force distribution of a front axle friction brake, a rear axle friction brake and an eddy current retarder is provided for the commercial vehicle equipped with an air pressure electric control braking system and the eddy current retarder, and the difference of the requirements of the emergency braking working condition, the long slope downhill braking working condition and other ordinary braking working conditions for the braking response speed, the braking distance, the brake temperature and the friction liner abrasion uniformity is taken into consideration, so that different control targets and different braking force distribution strategies are adopted according to different braking working conditions. The method has the advantages that the braking response speed of the braking system is increased, the temperature rise of the brakes under the downhill working condition is reduced, the service life of each friction liner is prolonged, accidents are avoided, the safety under various braking working conditions is improved, the service life of each friction brake and the service life of the eddy current retarder are prolonged, the maintenance frequency is reduced, and the economical performance is improved.

Owner:JILIN UNIV

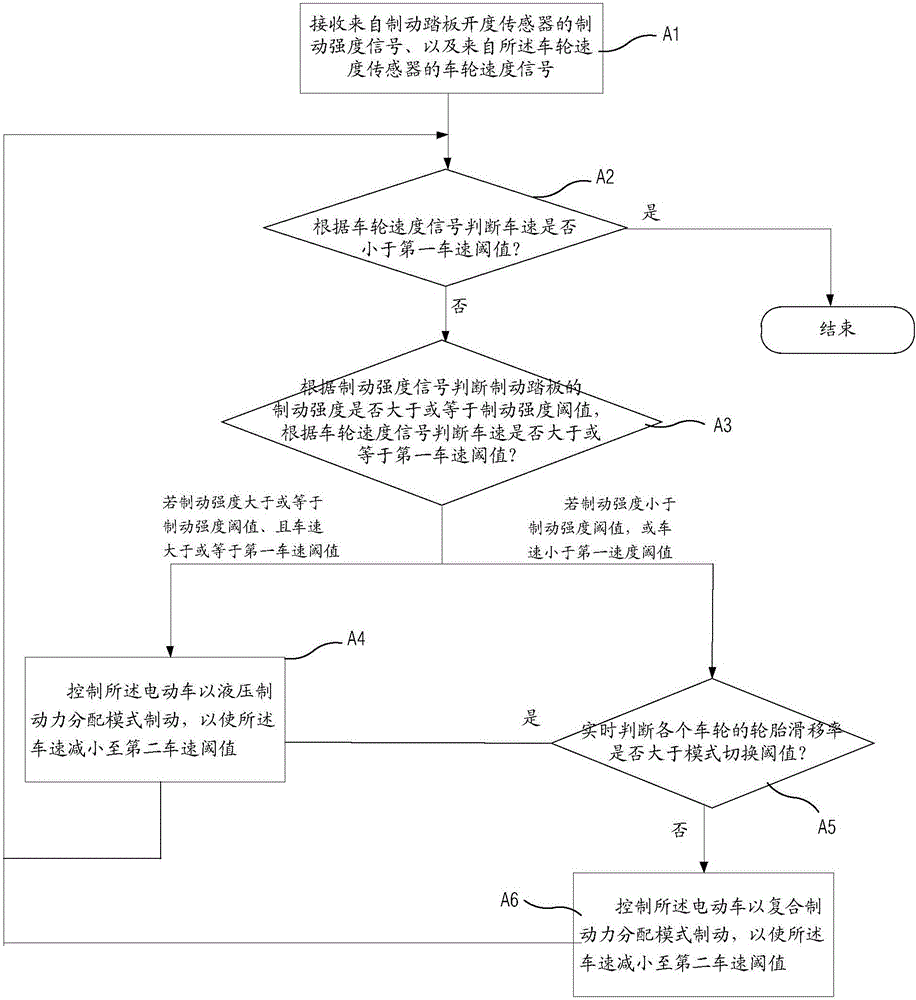

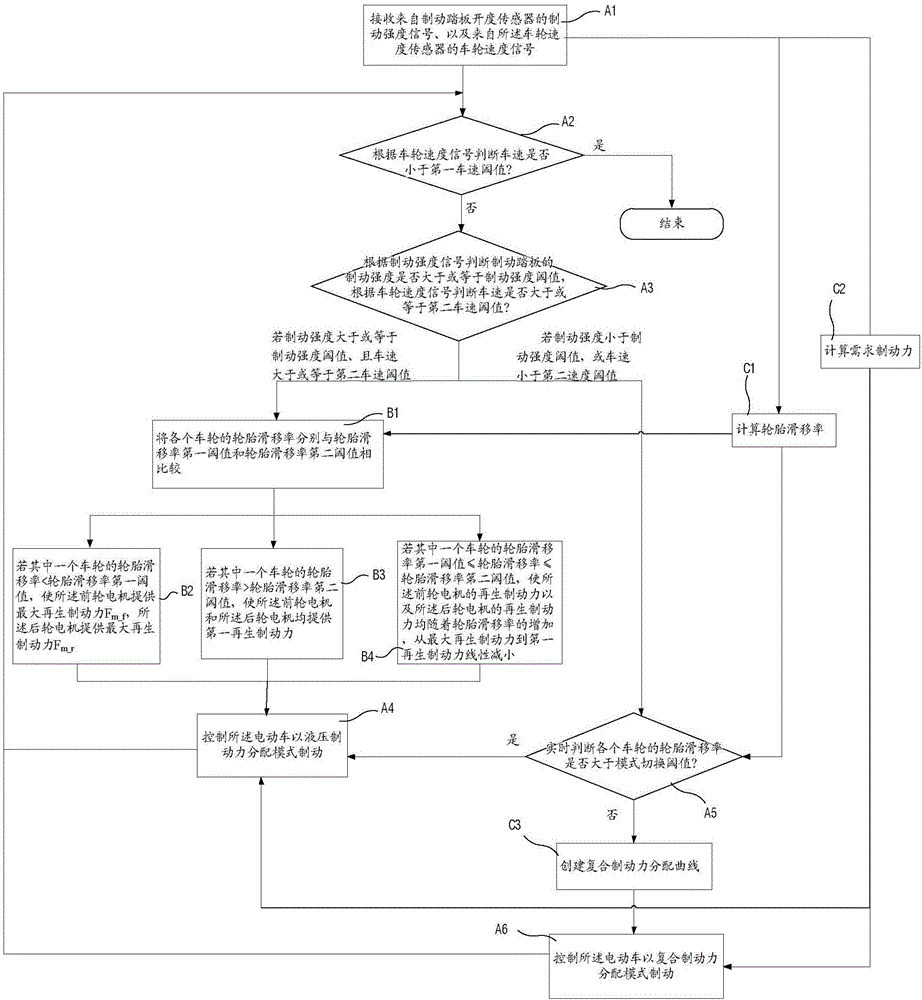

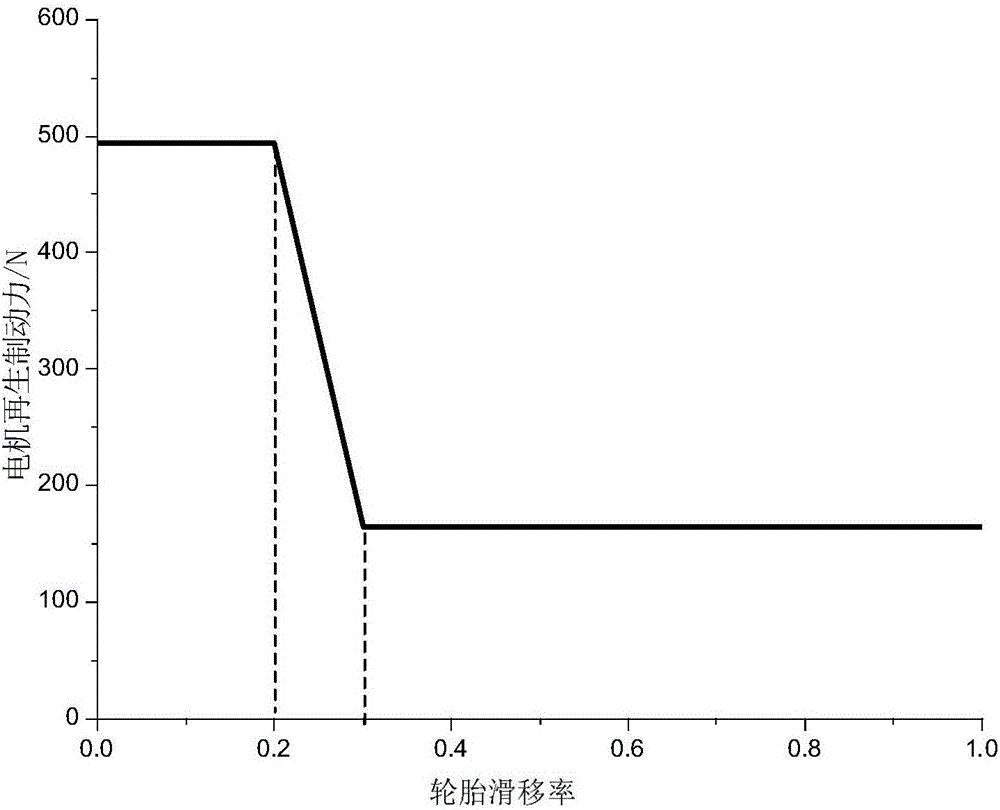

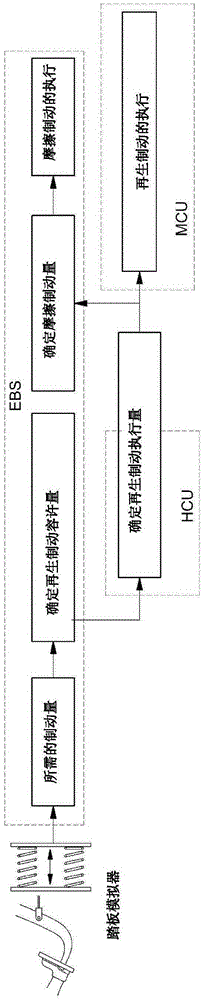

Braking control method and device of electric vehicle

InactiveCN106314163AFull recoveryAchieve recyclingElectrodynamic brake systemsRegenerative brakingWheel speed sensorElectric vehicle

The invention discloses a braking control method of an electric vehicle. The braking control method comprises: receiving a braking strength signal from a braking pedal opening degree sensor and a wheel speed signal from a wheel speed sensor; according to the wheel speed signal, judging whether a vehicle speed is smaller than a first vehicle speed threshold value or not; if so, finishing a flow; otherwise, judging whether braking strength of a braking pedal is greater than or equal to a braking strength threshold value or not according to the braking strength signal and judging whether the vehicle speed is greater than or equal to a second vehicle speed threshold value or not according to the wheel speed signal; if two conditions are both met, controlling the electric vehicle to be subjected to braking in a hydraulic braking force distribution mode; if only one condition is met, controlling the electric vehicle to be subjected to braking in a compound braking force distribution mode. According to the braking control method of the electric vehicle, provided by the invention, under the condition of guaranteeing the braking stability, braking energy is sufficiently recycled and the recycling of the energy is realized. The invention further discloses a braking control device of the electric vehicle.

Owner:CH AUTO TECH CORP CO LTD

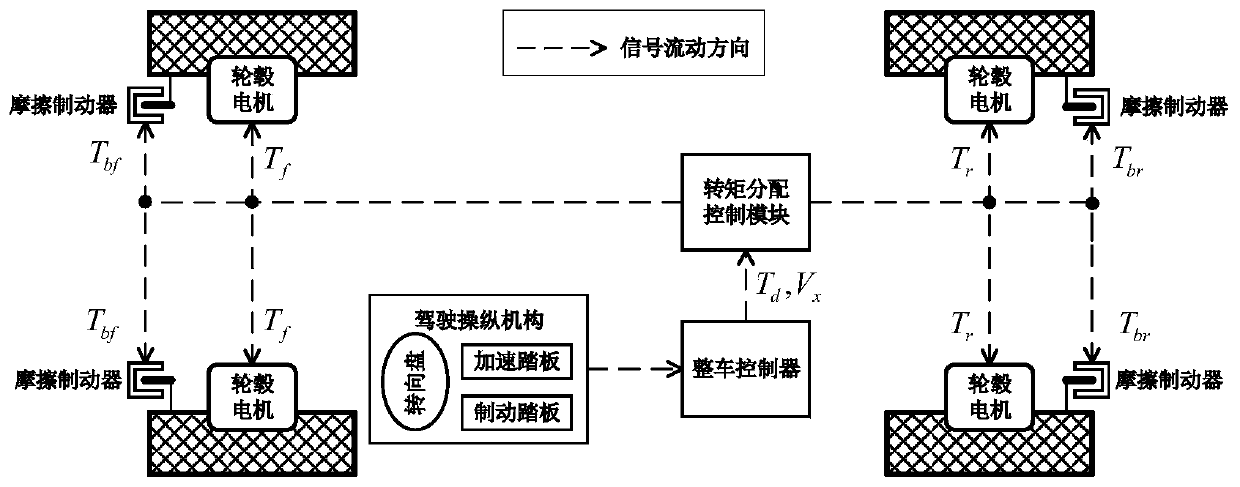

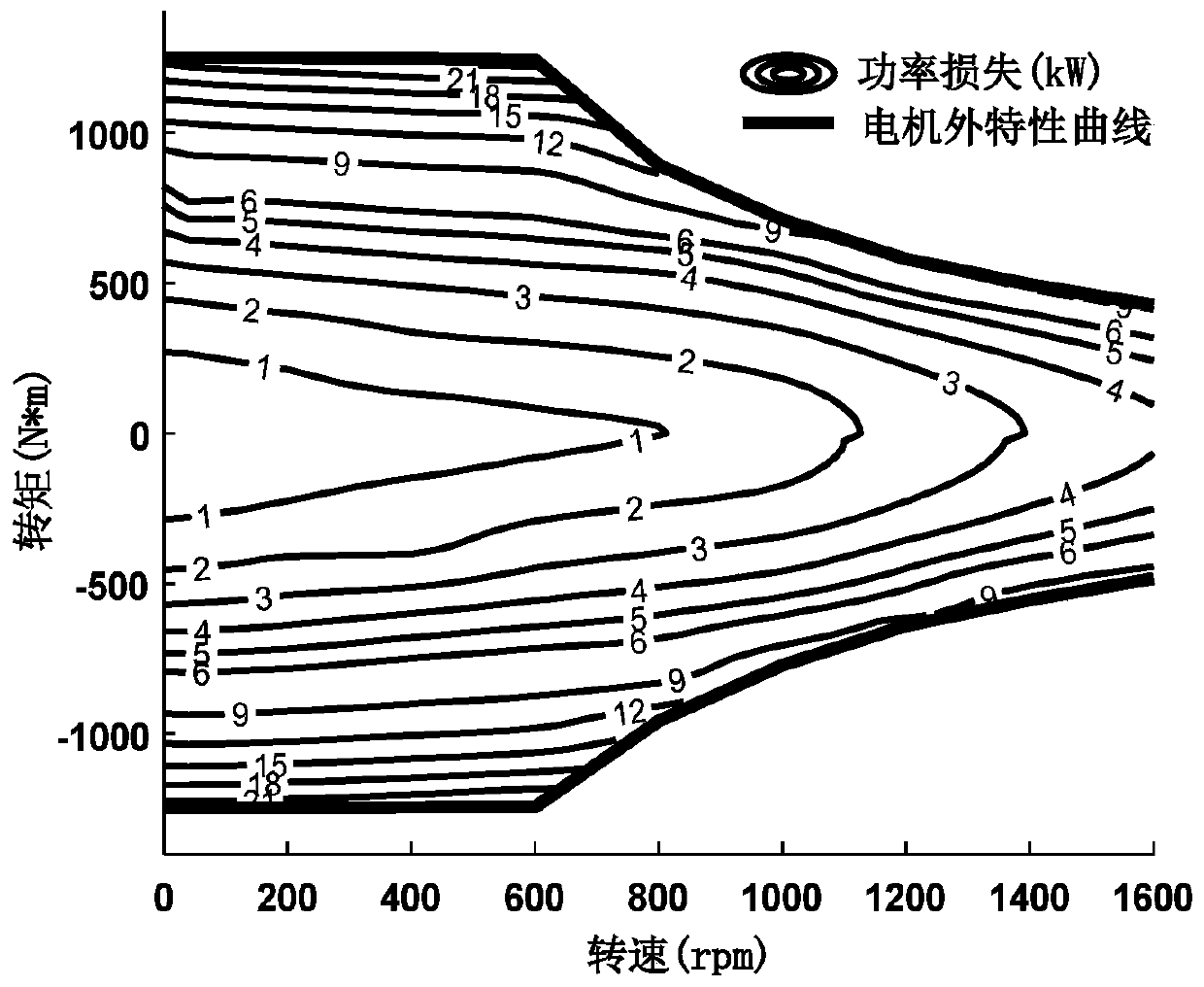

Straight driving cycle-oriented real-time optimal torque distribution control method for 4-wheel independent driving electric vehicle

ActiveCN110539647AImprove energy efficiencyGuaranteed powerSpeed controllerElectric devicesModularityTime optimal

The invention relates to a straight driving cycle-oriented real-time optimal torque distribution control method for a 4-wheel independent driving electric vehicle. In allusion to the problem of torquedistribution of a 4-wheel independent driving electric vehicle taking a wheel hub motor as a power unit under a straight driving cycle, a corresponding online optimal distribution control algorithm is formulated; an optimal distribution coefficient table acquired offline is further utilized to perform compensation and correction on an online optimal result; and a torque distribution function anddesign coupling of a vehicle controller are separated, and thereby, implementation of the modular design of control software is facilitated. The method realizes optimal torque distribution of the 4-wheel independent driving electric vehicle under the straight driving cycle, and thus, on the premise of satisfying the driving intention, the energy efficiency of a power assembly can be effectively increased, and meanwhile, it is guaranteed that power performance and braking stability of the vehicle meet the design indexes.

Owner:SOUTHEAST UNIV

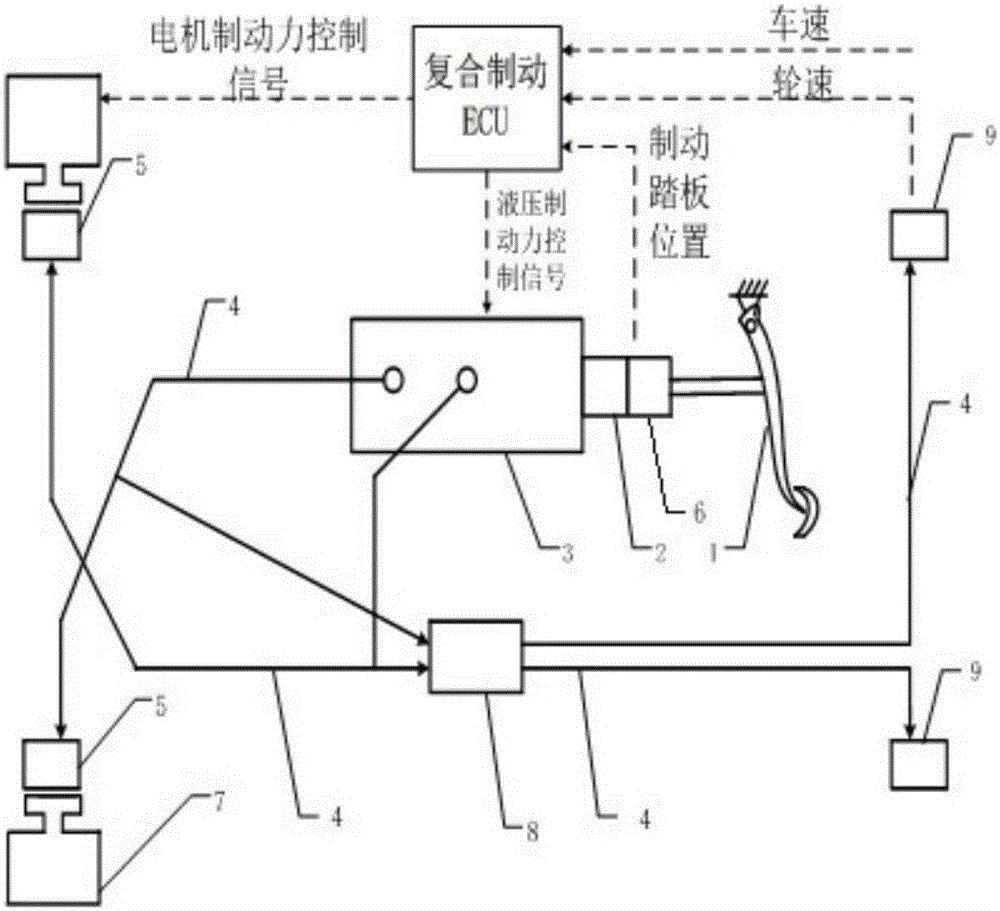

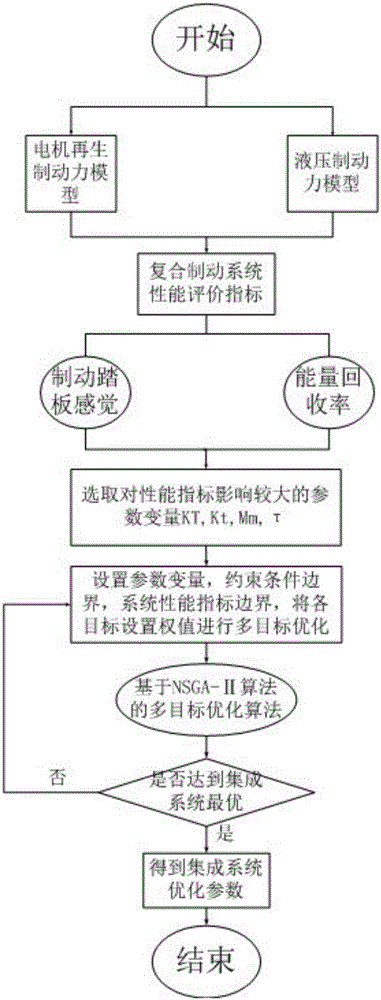

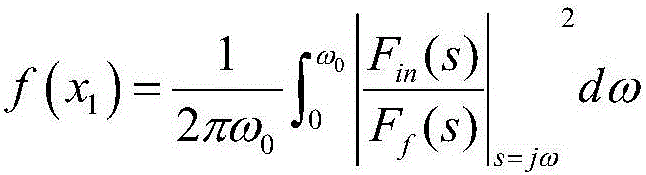

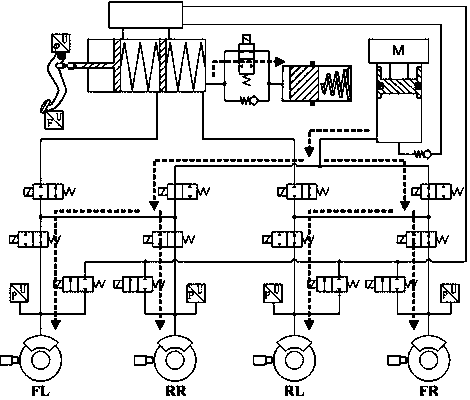

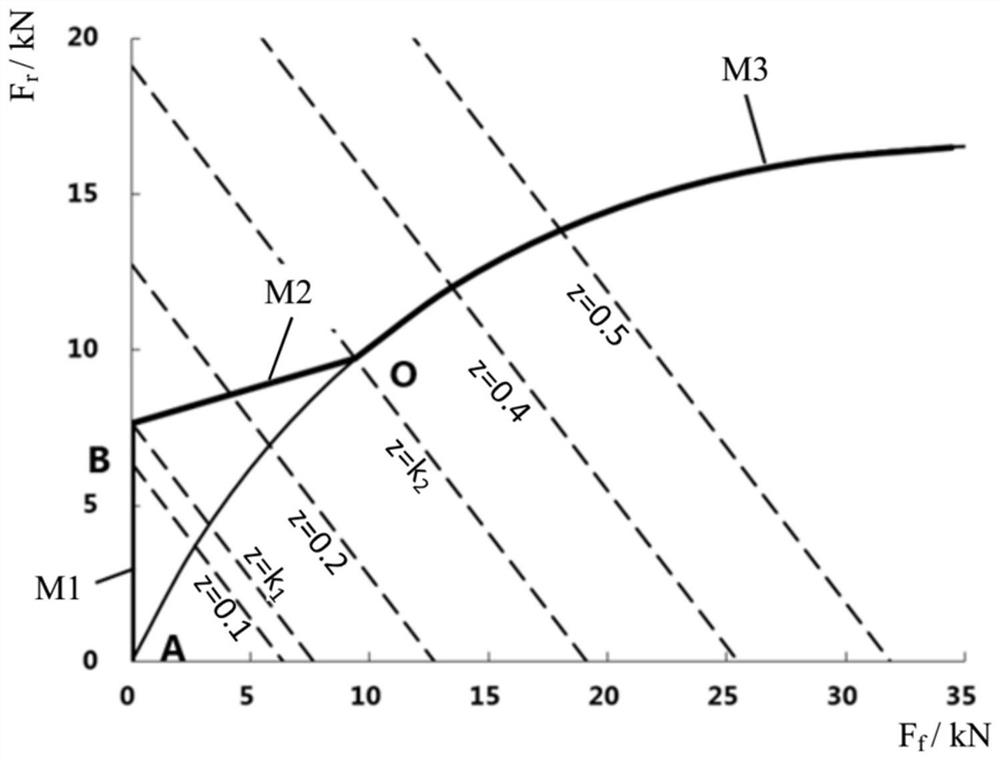

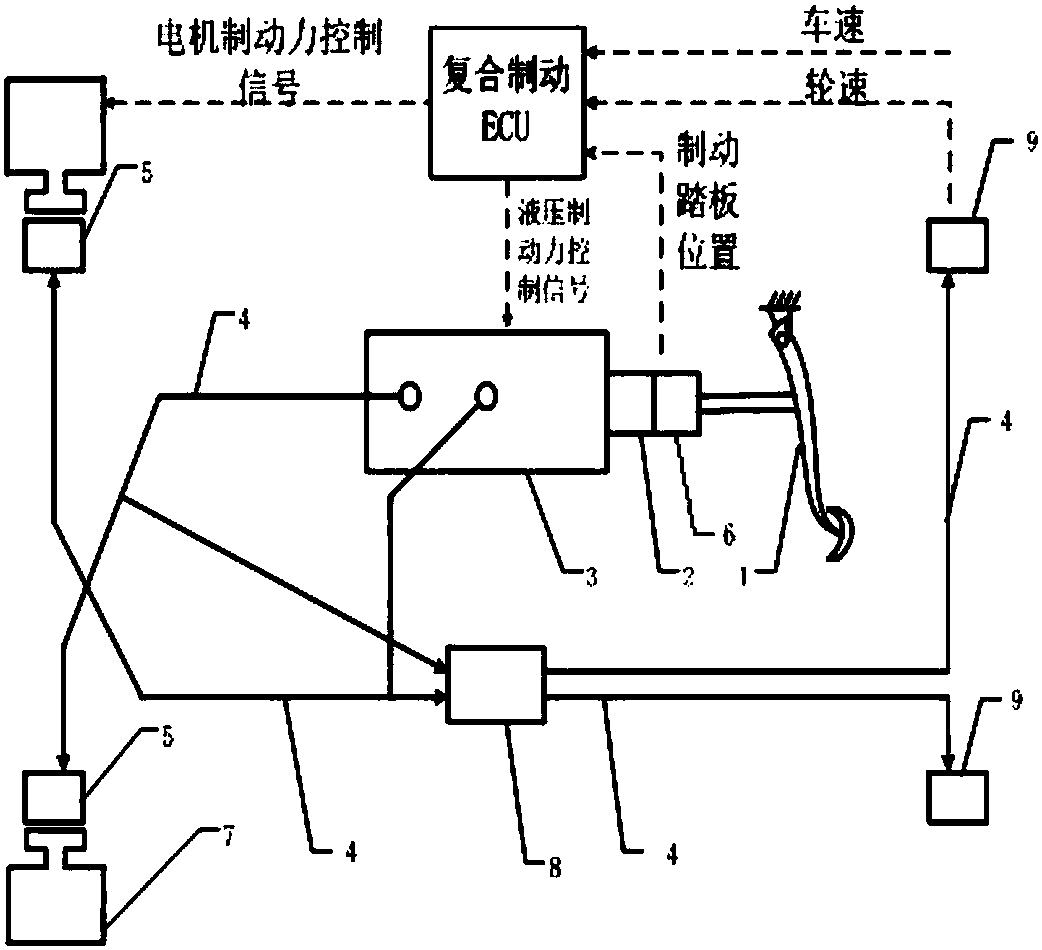

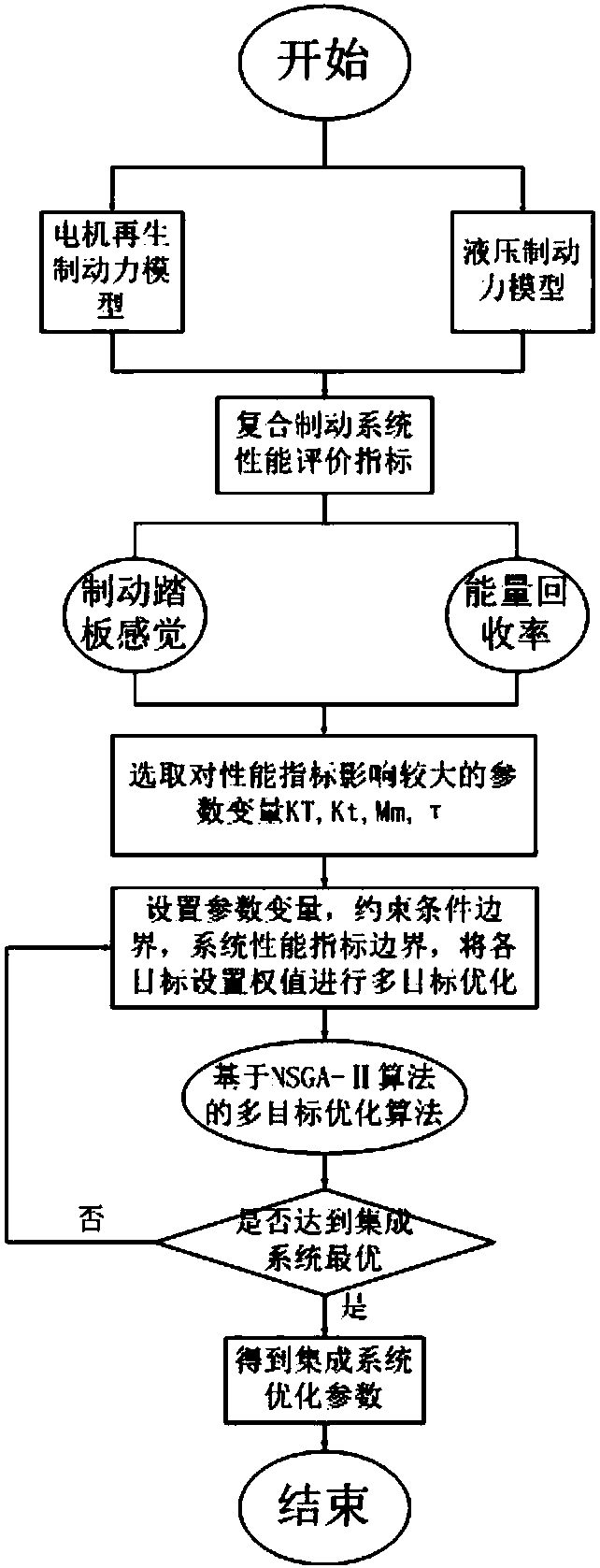

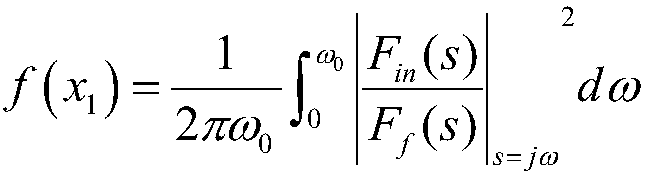

Electric-hydraulic composite braking system for electric automobile and optimization method of electric-hydraulic composite braking system

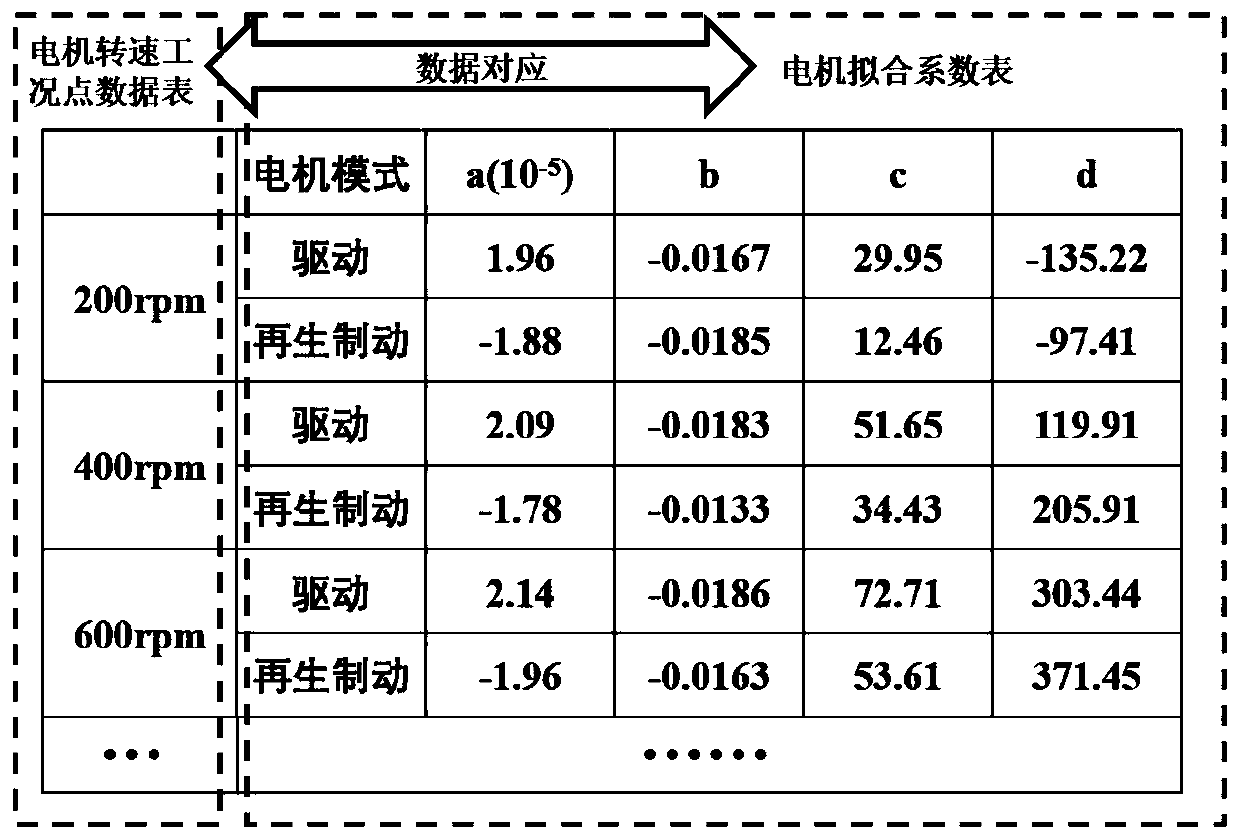

InactiveCN106043256AImprove braking efficiencyEasy to analyzeBraking action transmissionElectrodynamic brake systemsDc dc converterWheel speed sensor

The invention discloses an electric-hydraulic composite braking system for an electric automobile and an optimization method of the electric-hydraulic composite braking system. The electric-hydraulic composite braking system for the electric automobile comprises a motor regeneration braking force module, a hydraulic braking force module and a composite braking force control module. The motor regeneration braking force module comprises two hub motors, a brake pedal position sensor, four wheel speed sensors, an automobile speed sensor, a super-capacitor, a two-quadrant DC-DC converter and a first ECU. The hydraulic braking force module comprises an oil pump motor, a hydraulic oil pump and a second ECU. In the traveling process of the automobile, through detection of the automobile speed and the wheel speed of automobile traveling and brake pedal position signals, the composite braking force control module controls the distribution ratio between the motor regeneration braking force module and the hydraulic braking force module. Meanwhile, through multi-objective optimization conducted on the electric-hydraulic composite braking system, the braking pedal feeling and motor recovered energy serve as objects, and under the ECE laws and regulations, the relatively high energy recovery rate and the proper brake pedal feeling are obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

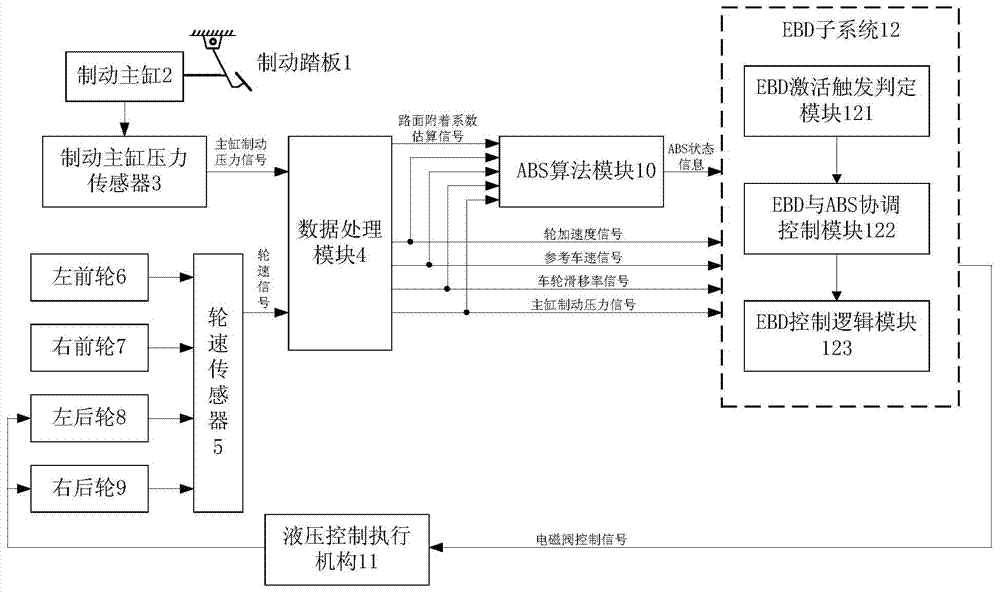

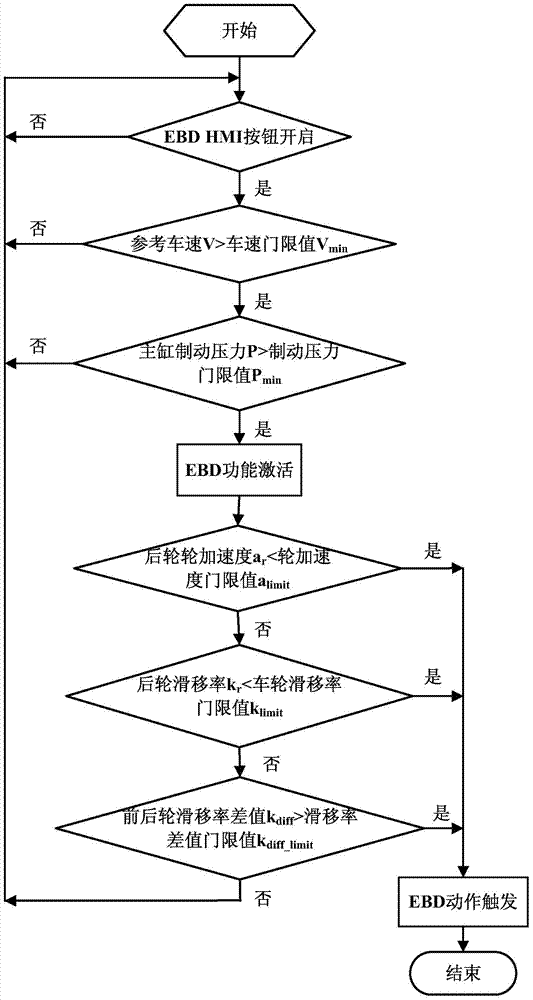

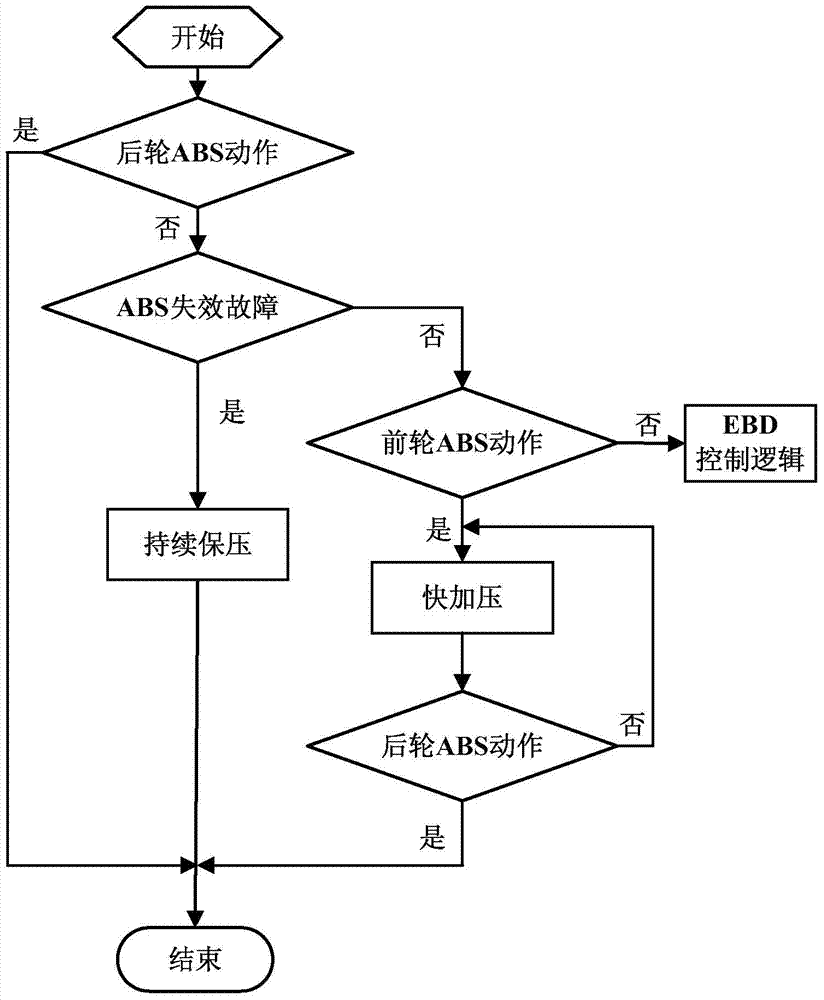

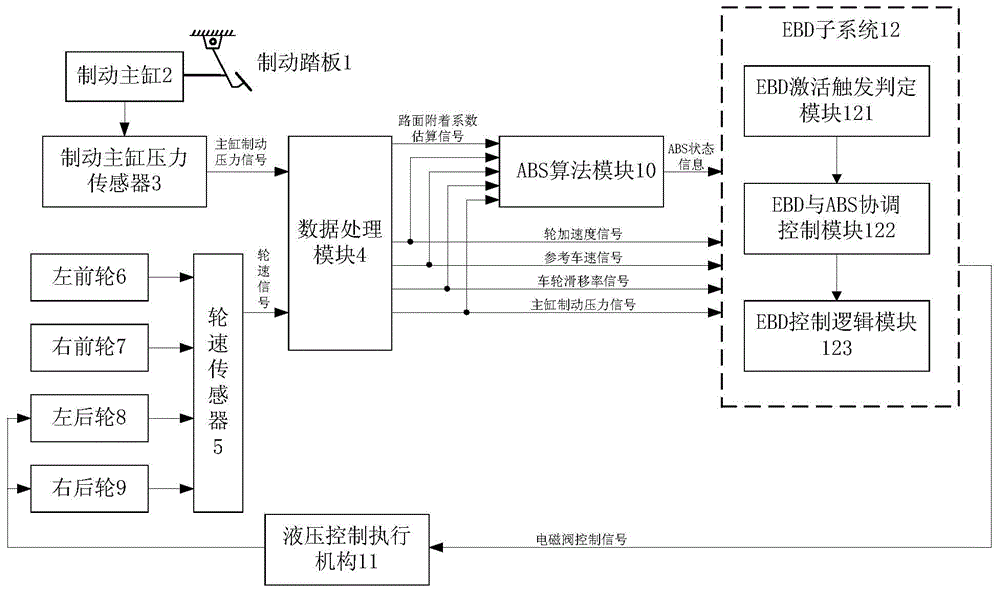

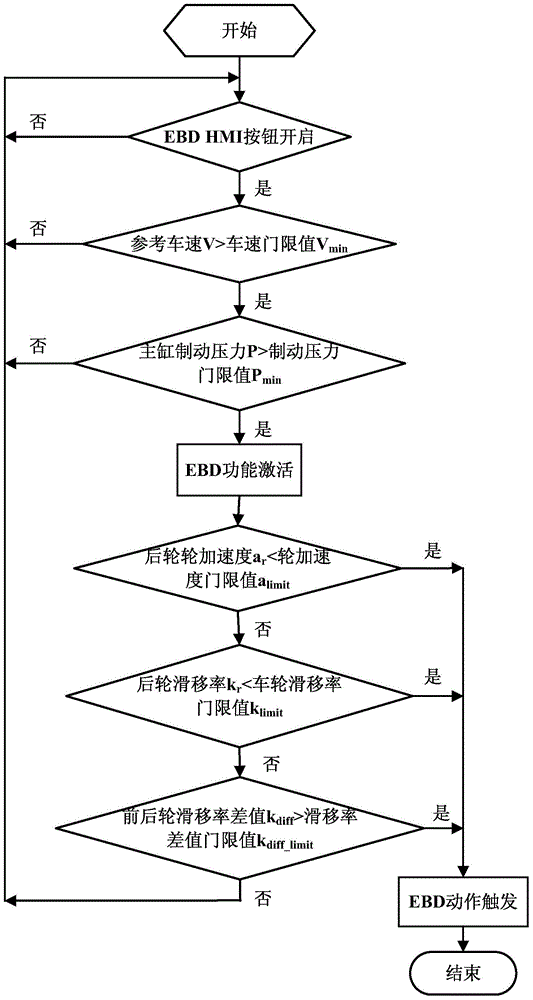

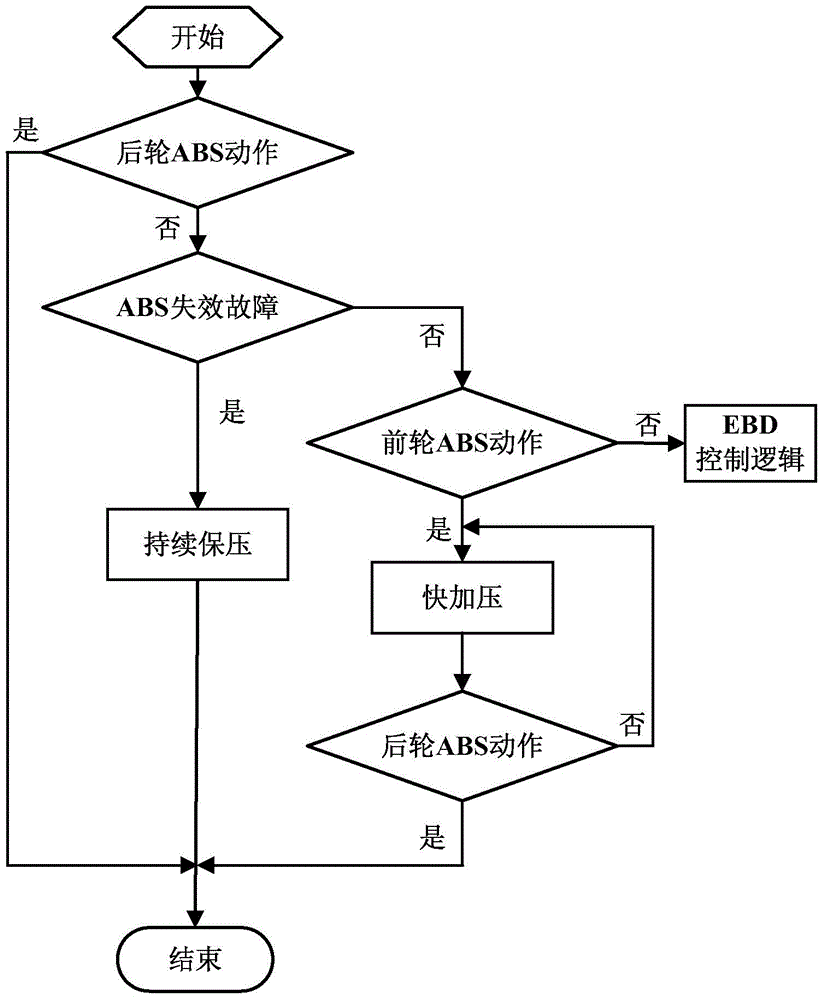

Control method for electronic brake-force distribution of automobile

ActiveCN103661334AGuaranteed timingIncreased braking potentialBraking systemsControl systemInlet valve

The invention relates to a control method for electronic brake-force distribution of an automobile. The control method includes the first step of setting an EBD subsystem in a general ABS control system, wherein the EBD subsystem comprises an EBD activation trigger and judgment module, an EBD and ABS coordination control module and an EBD control logic module, the second step of determining whether functions of the EBD subsystem need to be activated in the EBD activation trigger and judgment module, the third step of determining the best trigger time of movement of an EBD after the functions are activated, the fourth step of controlling the EBD subsystem to execute corresponding movement according to ABS conditions, detected by the EBD and ABS coordination control module, of front wheels and rear wheels after the movement of the EBD is triggered, and the fifth step of determining whether to enter the EBD control logic module, wherein the EBD control logic module sets the threshold value of critical slip ratio difference values to control the rear wheels to achieve circulating brake control over switching of pressurization, pressure maintenance and pressure reduction through the adoption of a logic threshold value control method based on slip ratio control, and controls brake force over the rear wheels through the adoption of the method combining time constant control and liquid inlet valve opening control. The control method for electronic brake-force distribution of the automobile can be widely applied to the automobile braking process.

Owner:BEIJING WONDER CAREWAY AUTOMOTIVE TECH

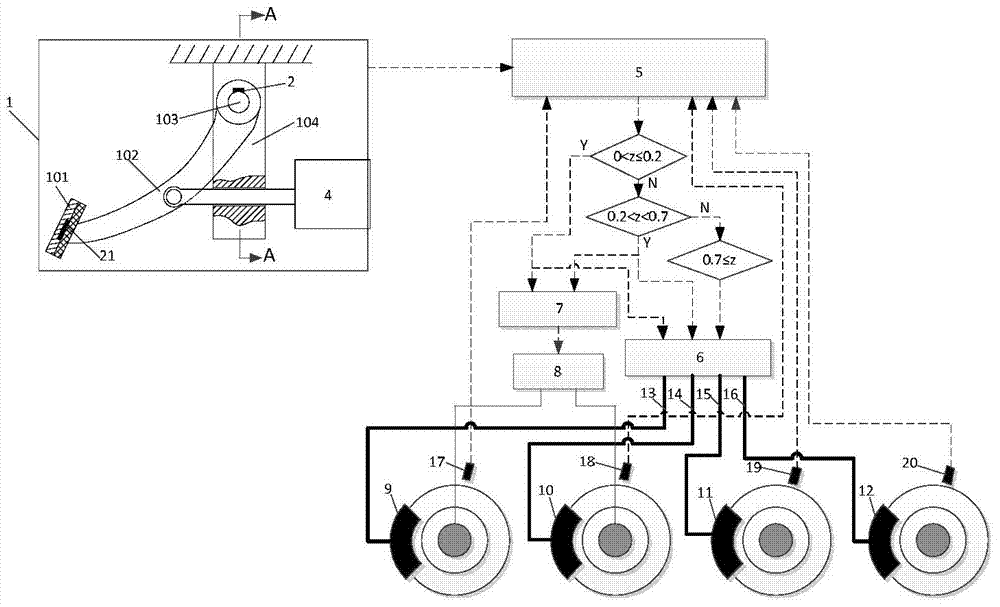

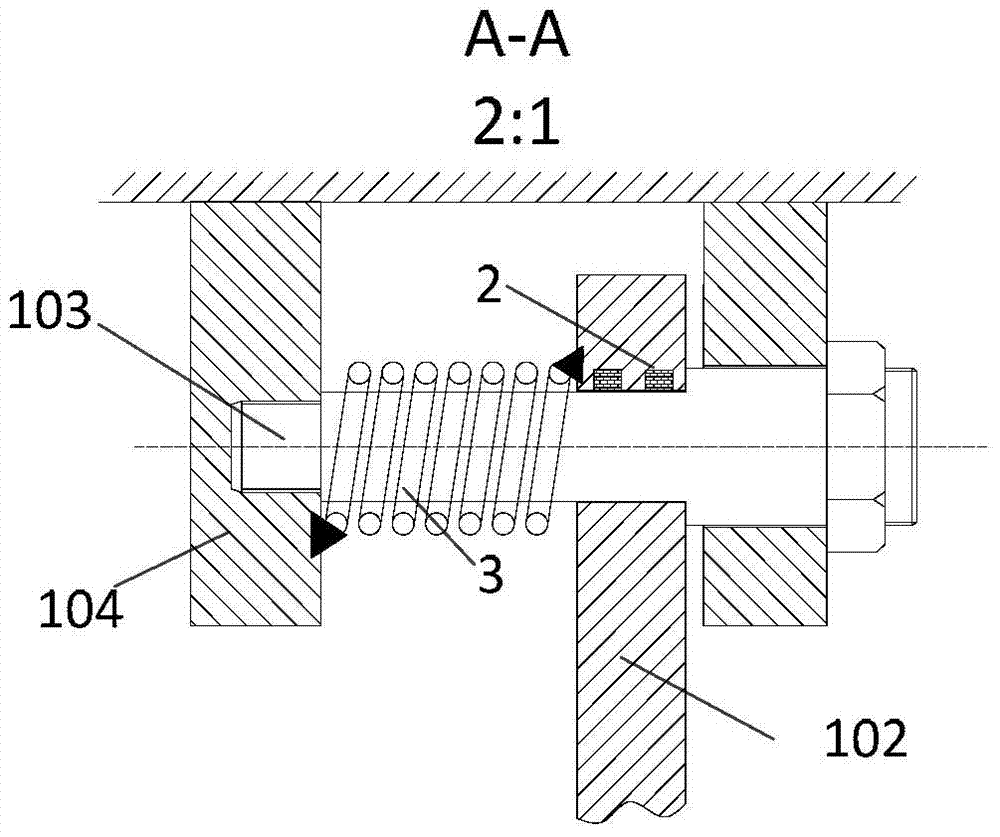

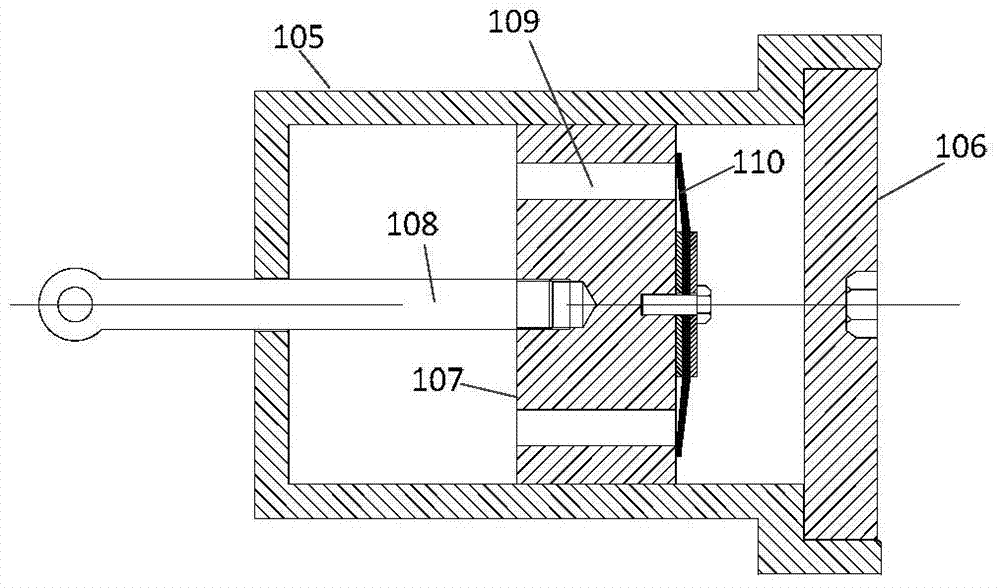

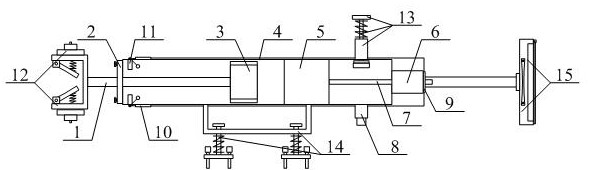

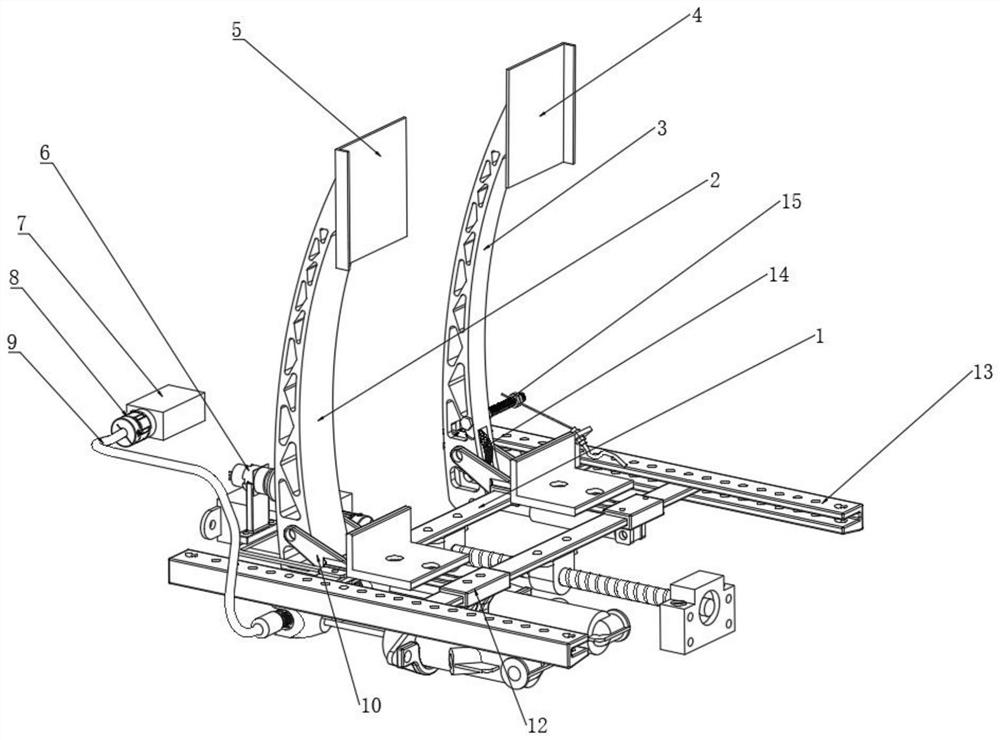

Line control brake system pedal force simulation and braking force control system of electric car

InactiveCN103481879AUniform braking decelerationSmall throttling resistanceElectrodynamic brake systemsFoot actuated initiationsDriver/operatorTorsion spring

The invention relates to a line control brake system pedal force simulation and a braking force control system of an electric car. The braking force control system comprises a braking operation mechanism, a pedal feel simulator, torsion springs, a pedal angular displacement sensor, a pedal force sensor and an electro-hydraulic composite braking control system. A pedal operating arm of the braking operation mechanism is connected with the front end of a push bar of the pedal feel simulator through hinge rotation. The torsion spring are loosely sleeved on a pedal shaft of the braking operation mechanism, one end of the pedal shaft is fixedly connected on a pedal fixing support, and the other end of the pedal shaft is fixedly connected with the pedal operating arm. The pedal angular displacement sensor is mounted in a round hole of the upper end of the pedal operating arm. The pedal force sensor is mounted on the braking pedal. Pedal angular displacement sensor signals and pedal force sensor signals are input to a control unit of the electro-hydraulic composite braking control system. By the aid of the braking force control system, feeling of a braking pedal can be simulated, a good response is brought to acting force of the pedal, and braking forces of front and rear shafts of the electric car are controlled by identifying braking intention of a driver and calculating braking intensity.

Owner:BEIHANG UNIV

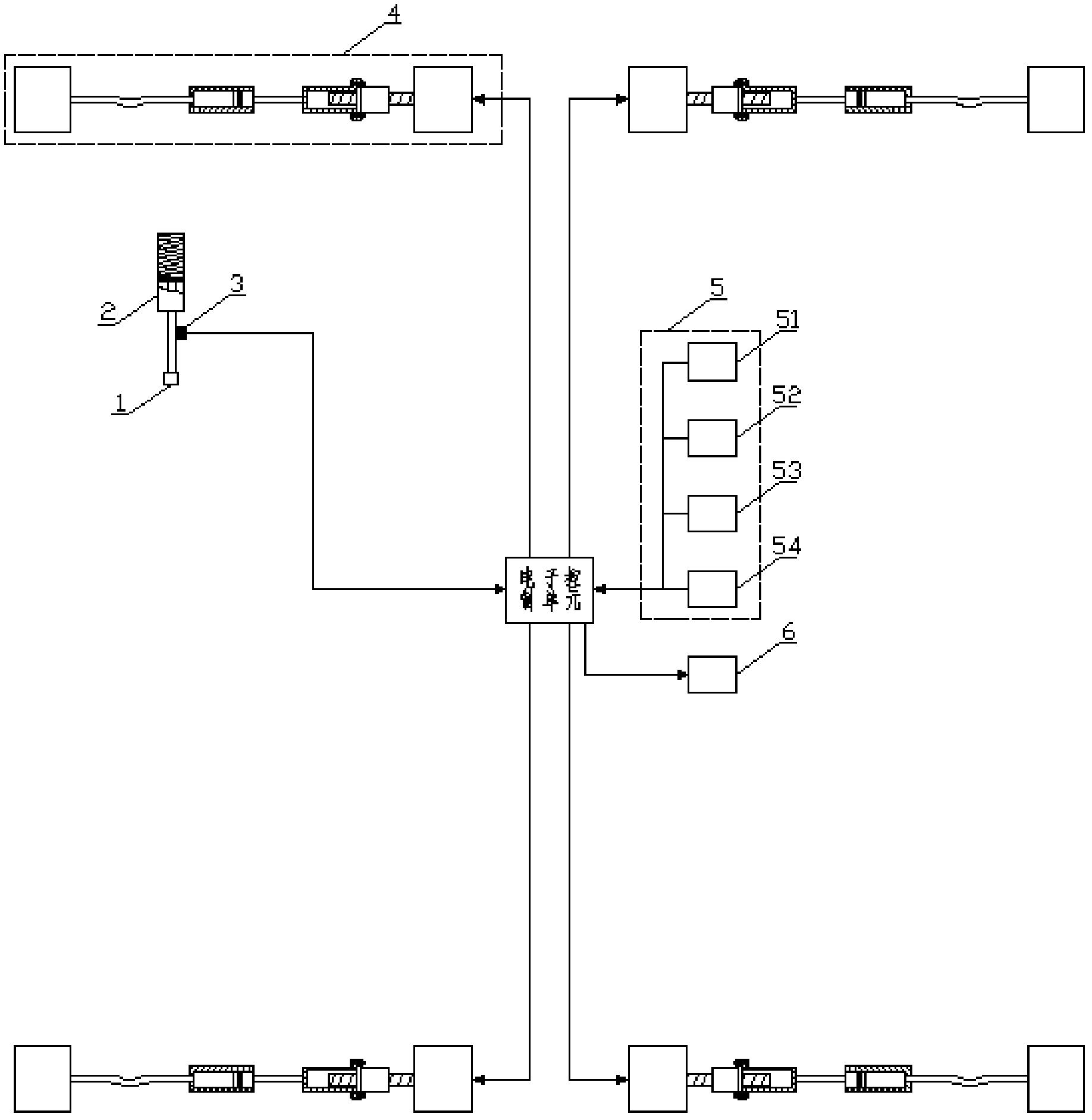

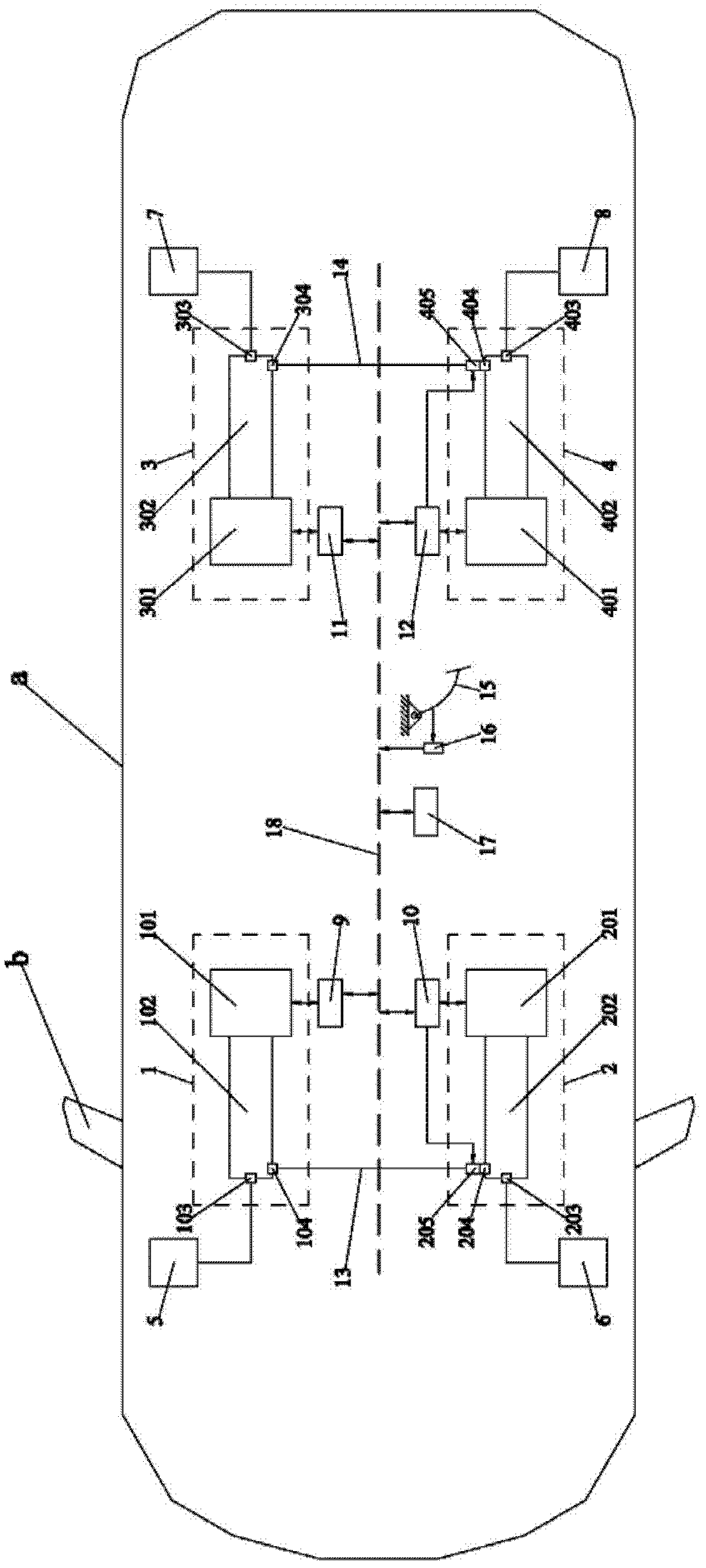

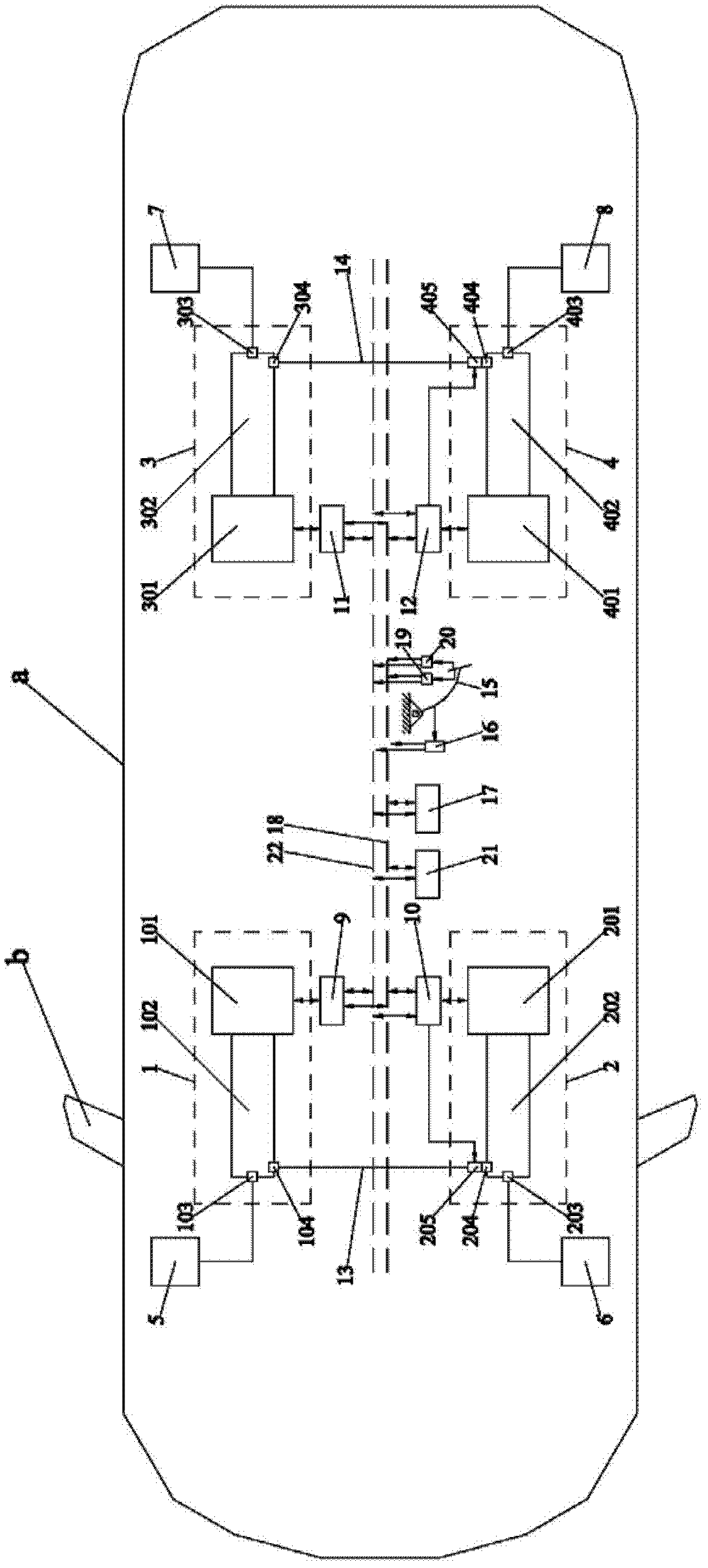

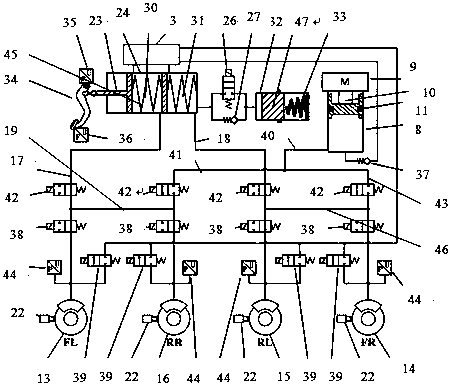

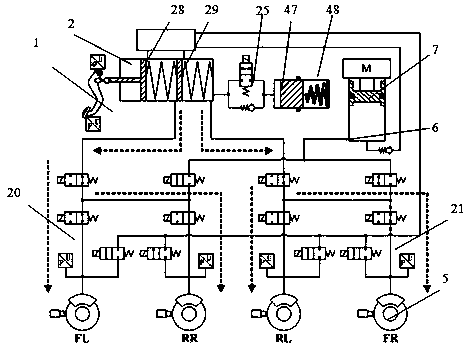

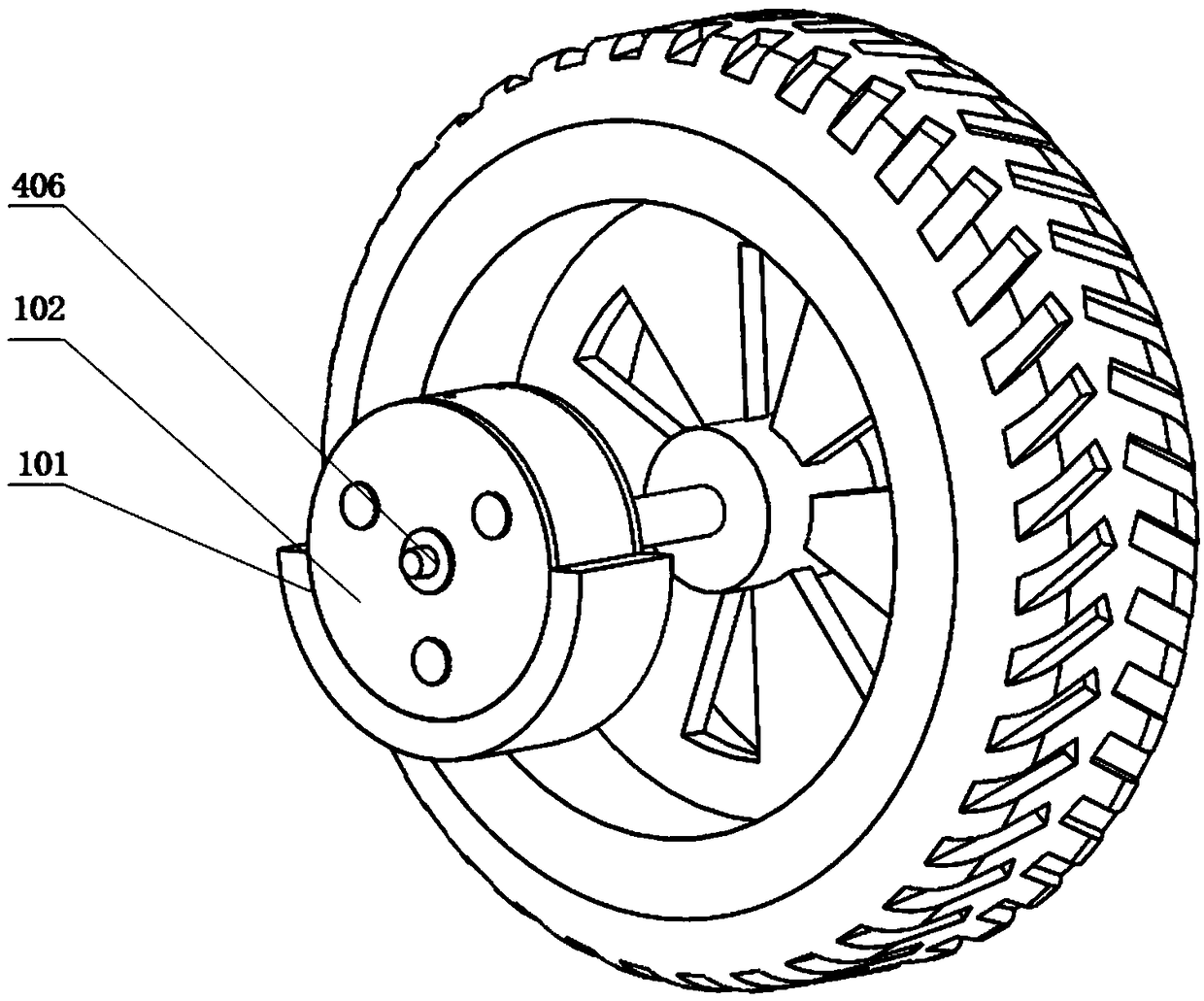

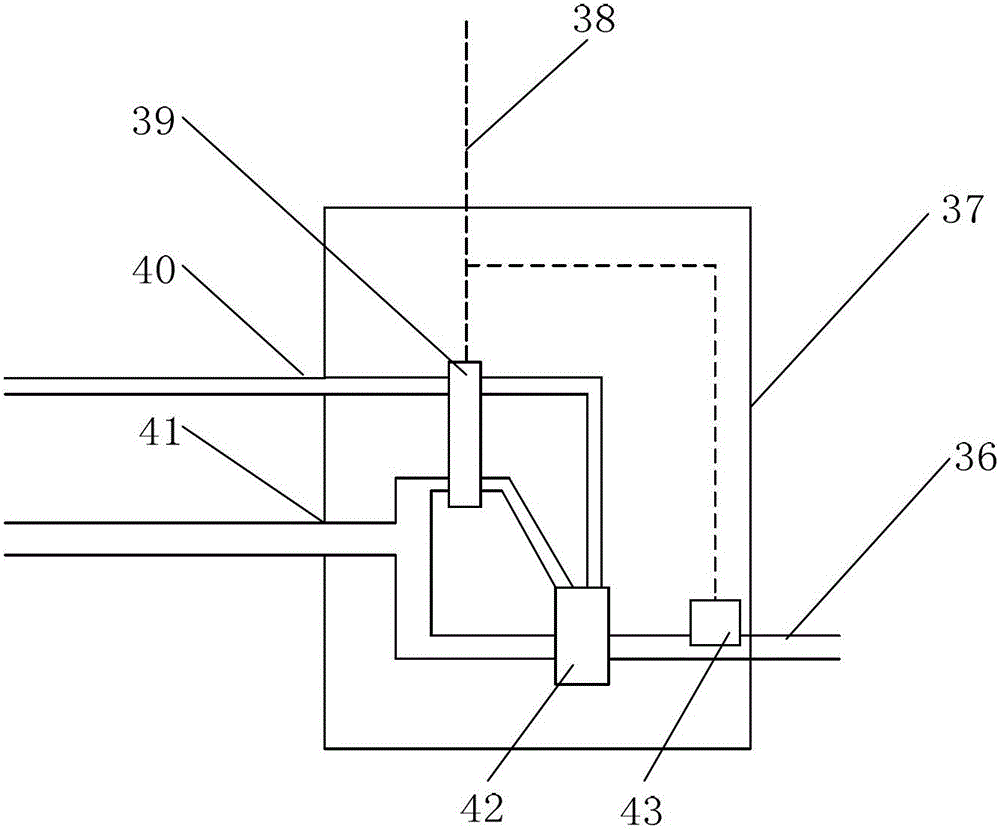

Distributed type electronic hydraulic brake system using isolating valves

ActiveCN102490711AGuaranteed braking effectEnsure braking stabilityBraking action transmissionHydraulic cylinderActive safety

The invention relates to a distributed type electronic hydraulic brake system using isolating valves and belongs to the field of active safety of automobiles. The distributed type electronic hydraulic brake system comprises four brake actuating mechanisms, four brakes, two isolating valves, four actuating mechanism controllers, a brake pedal, one pedal sensor, a line control brake controller, a bus and a brake pipeline. Each brake actuating mechanism is composed of a motor and a hydraulic cylinder. Each hydraulic cylinder is provided with two oil outlets, one of the two oil outlets is connected with the brakes, and the other oil outlet is connected with the isolating valves. One of the two isolating valves is used for being connected with the brake actuating mechanisms of two front wheels, and the other isolating valve is used for being connected with the brake actuating mechanisms of two rear wheels. The distributed type electronic hydraulic brake system using the isolating valves can improve reliability.

Owner:TSINGHUA UNIV

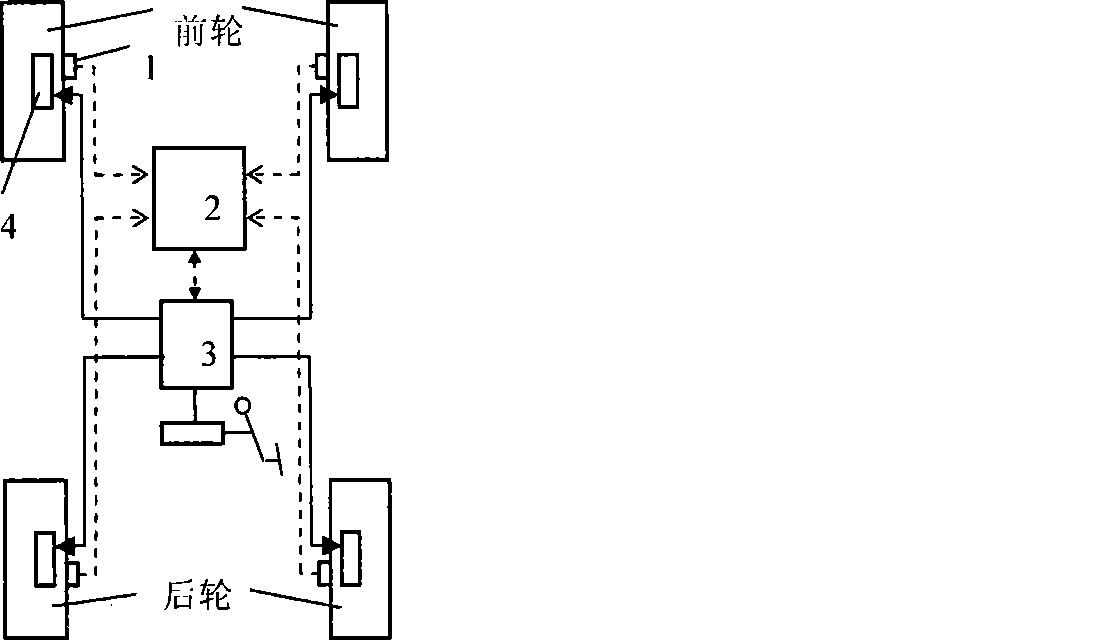

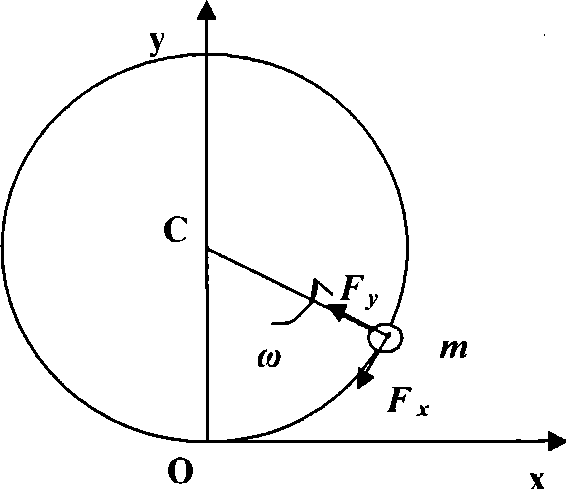

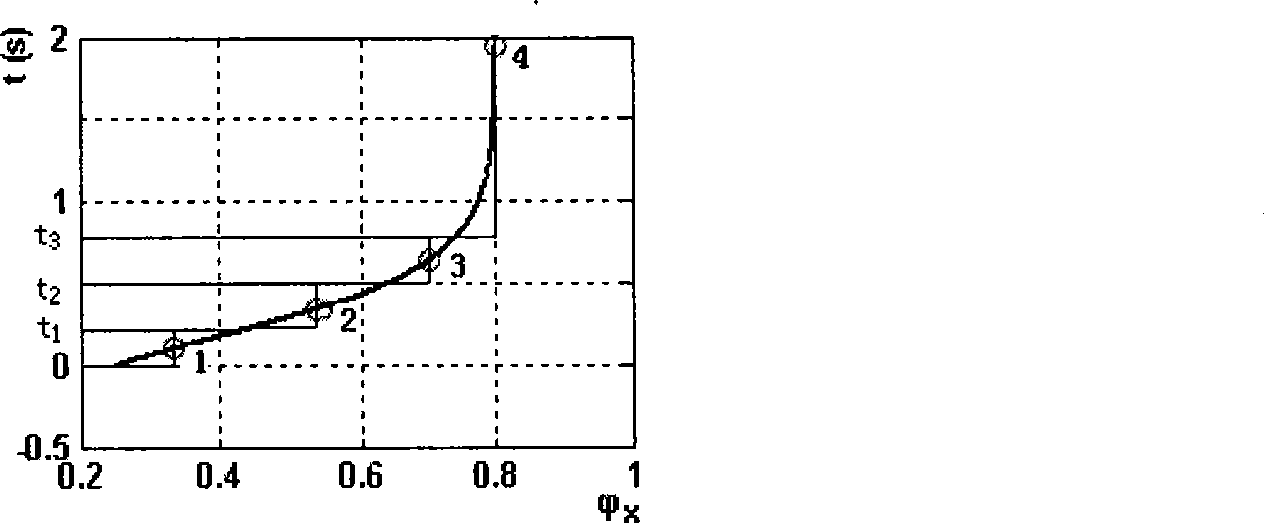

Vehicle bend brake stability ladder control system

InactiveCN101380946AGuaranteed stabilityIncrease braking strengthBraking systemsAutomotive engineeringResultant force

The invention discloses a vehicle bend braking stability step control system which implements the step control on a total braking force Fx during the vehicle bend braking and the distribution of the total braking force on a front wheel and a back wheel by a braking force adjusting device according to different time points during the braking process of turning radius, vehicle speed and road attachment conditions during the vehicle bend braking. The upper limit of the total braking force Fx and the resultant force of a total lateral force Fy (equal to vehicle centrifugal force) form a vehicle limit adhesion force. The slip ratio of each wheel is controlled so as to maintain the total braking force Fx within the upper limit. Thus, the vehicle adhesion force is controlled within the limit adhesion force. When the vehicle speed during the braking process is lowered continuously, the centrifugal force is reduced continuously. The adjustment of the control system is not frequent according to a discipline that the upper limit of the total braking force of the vehicle changes with the braking time. The target slip ratio of the wheel at different time points is regulated according to time segments so as to ensure that the vehicle adhesion force during the braking process is within the limit adhesion force, so that the braking stability of the vehicle bend is guaranteed.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Regenerative braking system and braking method for wheel hub motor-driven automobile

ActiveCN108263216AImprove energy recoveryImprove braking efficiencyBraking action transmissionElectrodynamic brake systemsBrake torqueMotor drive

The invention discloses a regenerative braking system for a wheel hub motor-driven automobile. A motor braking and hydraulic braking composite mode can be realized to enhance the braking efficiency. The invention further provides a regenerative braking method for the wheel hub motor-driven automobile. The regenerative braking method for the wheel hub motor-driven automobile comprises the followingsteps of step 1, obtaining total braking torque needed by braking according to pedal displacement, distributing the total braking torque to a front axle and a rear axle according to a fixed proportion and uniformly distributing braking forces of the front axle and the rear axle to corresponding wheels, wherein the motor braking force and hydraulic braking force of each wheel are independently controlled; step 2, obtaining the rotation speed of a wheel hub motor according to the current wheel rotation speeds and calculating maximum braking torque Tm, which can be provided by the wheel hub motor; and step 3, when the desired braking forces Trep of the wheels are less than 0.8 Tm, executing a pure motor braking mode; when the desired braking forces Trep of the wheels are not less than 0.8 Tm, executing a composite braking mode of the wheel hub motor braking and hydraulic braking; and after the automobile speed is decelerated to 10 km / h, entering a pure hydraulic braking mode, closing a wheel hub motor regenerative sub system and opening a pressure increasing valve to enhance the braking efficiency.

Owner:JILIN UNIV

Optimization method of braking force distribution in commercial vehicle integrated braking system under different working conditions

InactiveCN105292092BQuick responseGuarantee different needsBraking action transmissionElectrodynamic brake systemsEddy currentElectric control

Owner:JILIN UNIV

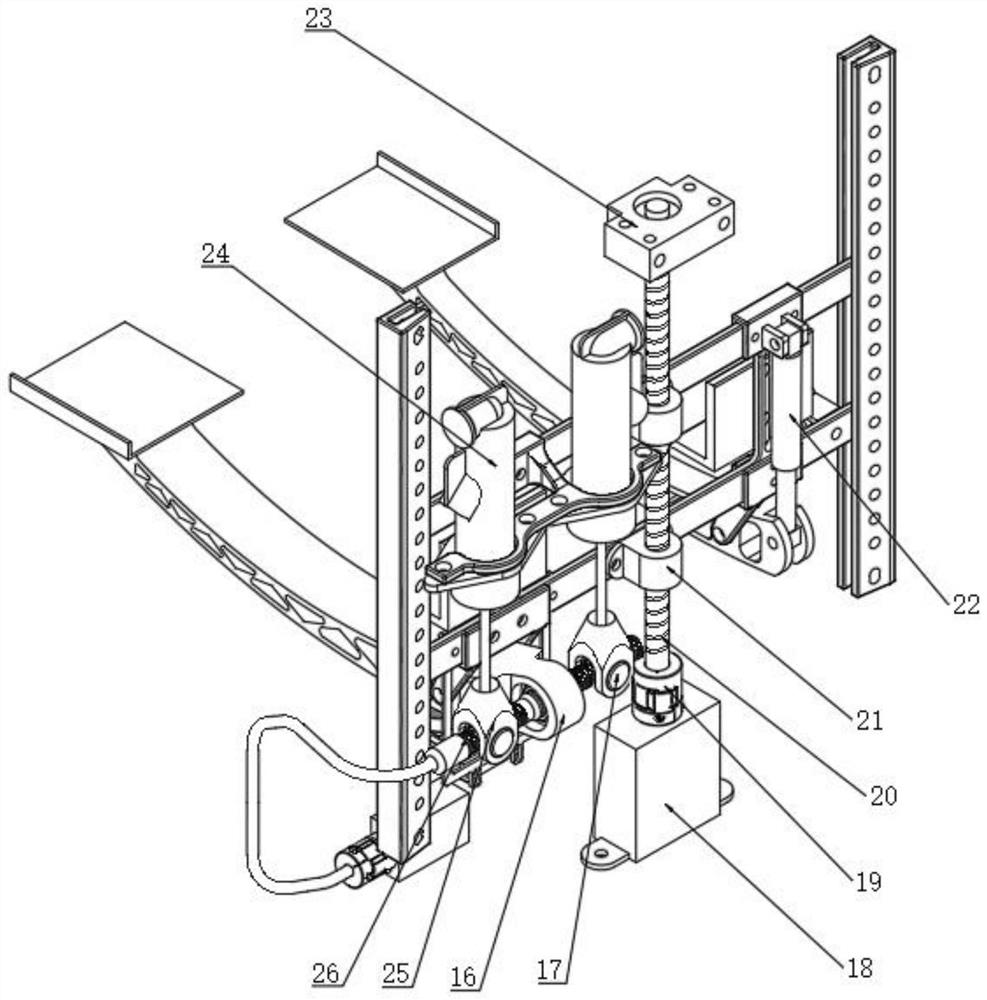

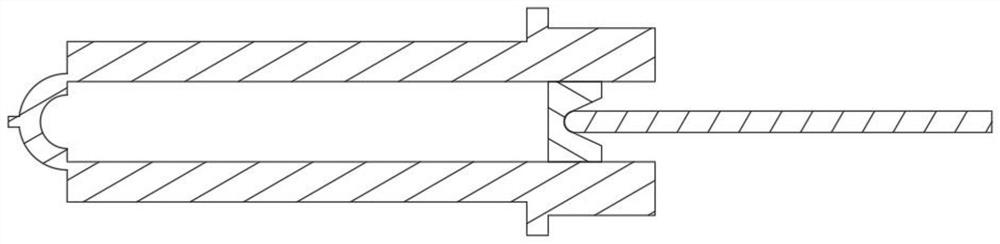

Integrated electric servo brake system for vehicle

InactiveCN109927692AReasonable designEfficient recyclingBraking action transmissionBall screw driveMotor drive

The invention provides an integrated electric servo brake system for a vehicle. The system comprises a brake operating mechanism, a brake main cylinder assembly, a wheel brake assembly and a hydraulicloop. The brake main cylinder assembly comprises a liquid storage tank; the brake operating mechanism is in transmission connection with the brake main cylinder assembly; the wheel brake assembly includes a brake wheel cylinder; the brake main cylinder assembly is communicated with the brake wheel cylinder; the hydraulic loop includes a supercharging module; the supercharging module comprises a supercharging cylinder body, a motor and a ball screw which is in rigid connection with the motor, wherein a hydraulic piston is arranged in the supercharging cylinder body and installed on the inner side of a ball screw cylinder body; the ball screw is also connected with the hydraulic piston, the motor drives the ball screw to move, and correspondingly the ball screw drives the hydraulic piston to move; one end of the supercharging module is communicated with the liquid storage tank, and the other end of the supercharging module is communicated with the brake wheel cylinder. The whole reliability of the system is improved, and working noise, installation volume and weight are reduced.

Owner:WANXIANGQIANCHAO CO LTD +1

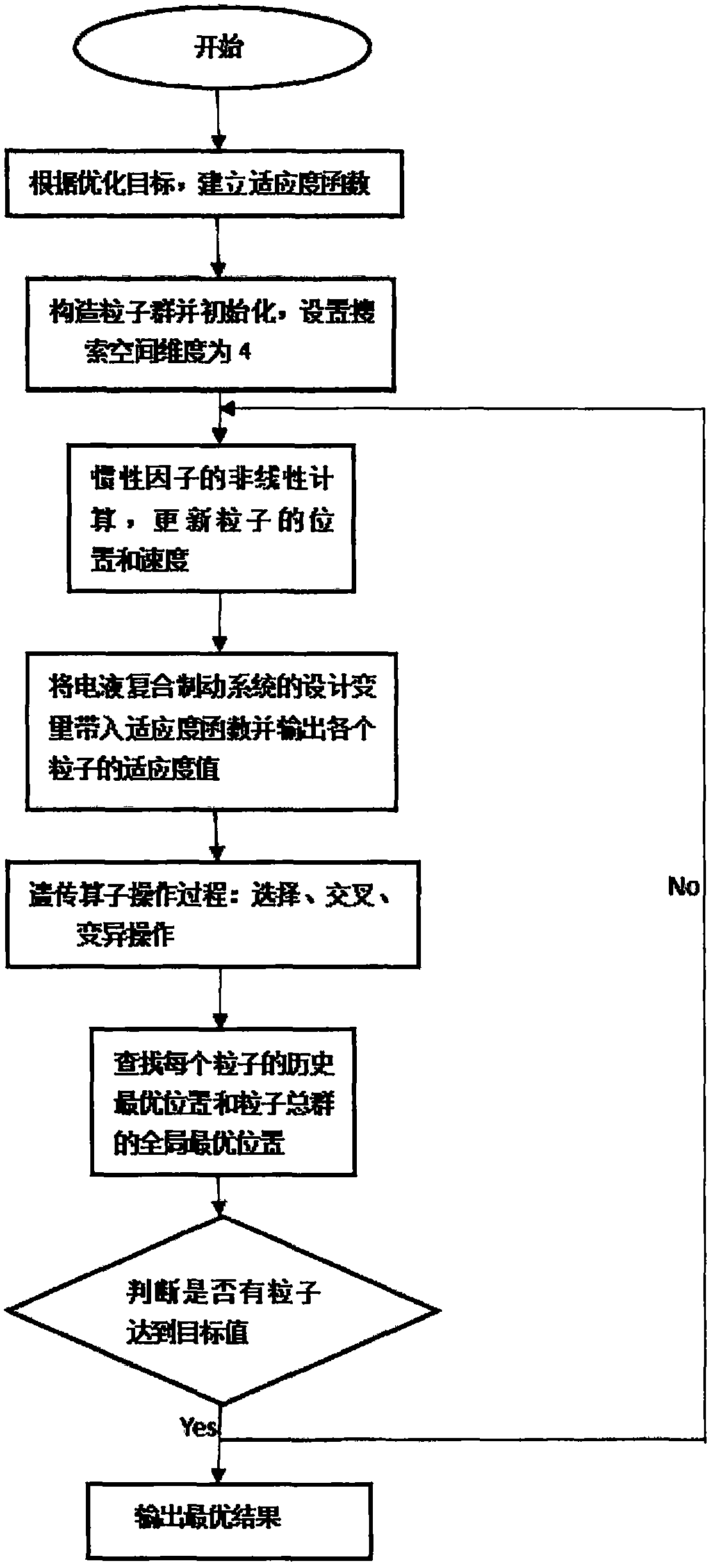

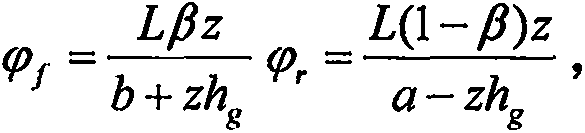

Method for optimizing braking force distribution in electro-hydraulic compound braking system

ActiveCN107253442AEnsure braking stabilityRecovery of braking energyElectrodynamic brake systemsGenetic modelsElectro hydraulicBattery electric vehicle

The invention provides a method for optimizing braking force distribution in an electro-hydraulic compound braking system, belongs to the technical field of electro-hydraulic compound braking and relates to the field of swarm intelligent algorithms. According to the requirements of pure electric vehicle of different types or pure electric vehicles of a certain type for the braking stability and braking energy recycling efficiency, the contradictory relation of the braking stability and the braking energy recycling efficiency to a certain extent in an electromechanical hybrid braking area is comprehensively considered; and the parameter of the electro-hydraulic compound braking system is optimized through an improved particle swarm algorithm with the high global searching ability, an adaptability function serving as the optimizing judgment standard is established, and the historical global optimum value of a particle swarm is obtained and serves as the parameter meeting the needed electro-hydraulic compound braking system. The algorithm is simple, the global searching ability is high, the convergence rate is high, the braking stability of vehicles in the braking process is guaranteed, and meanwhile braking energy of a motor is recycled to the largest extent.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

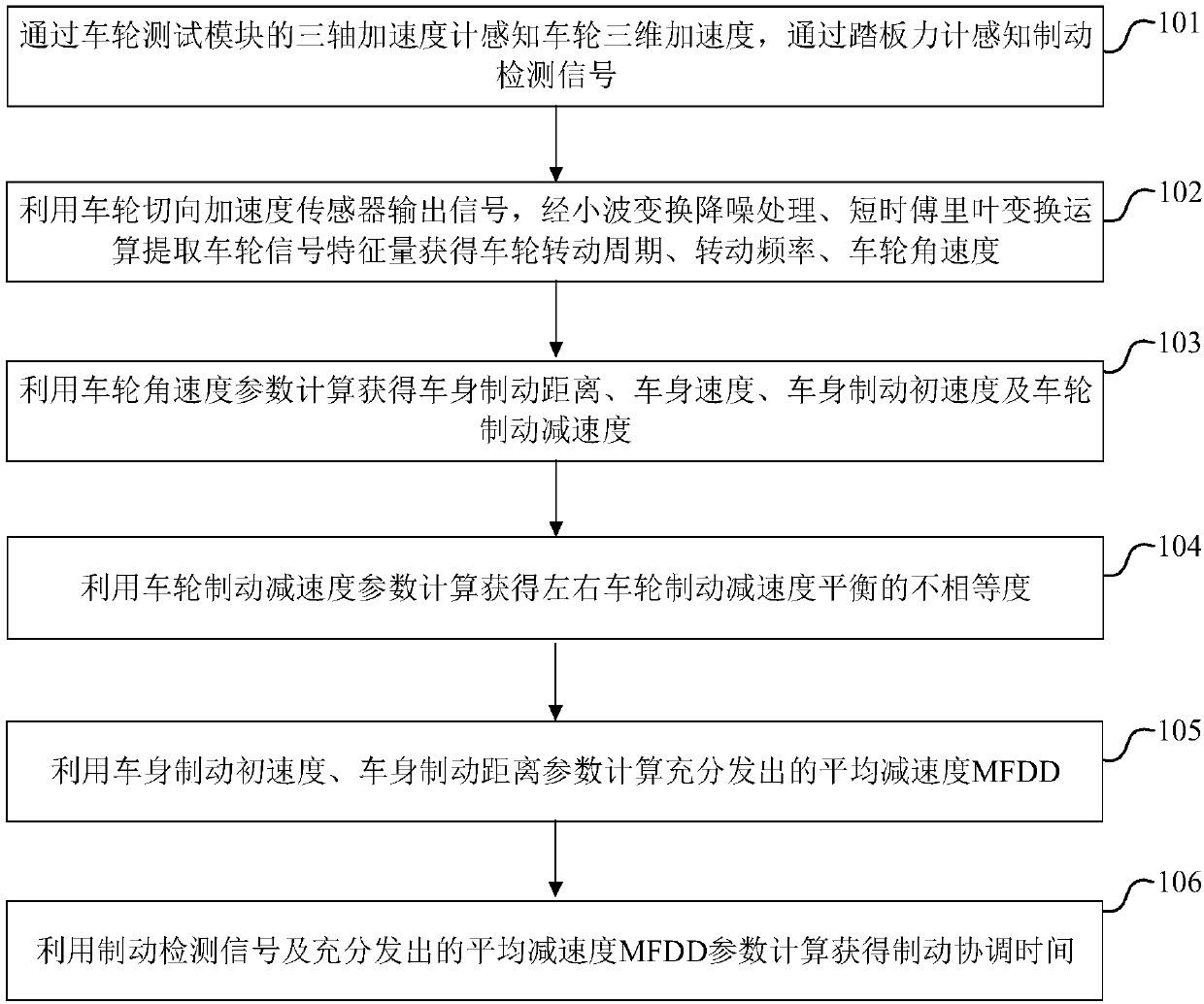

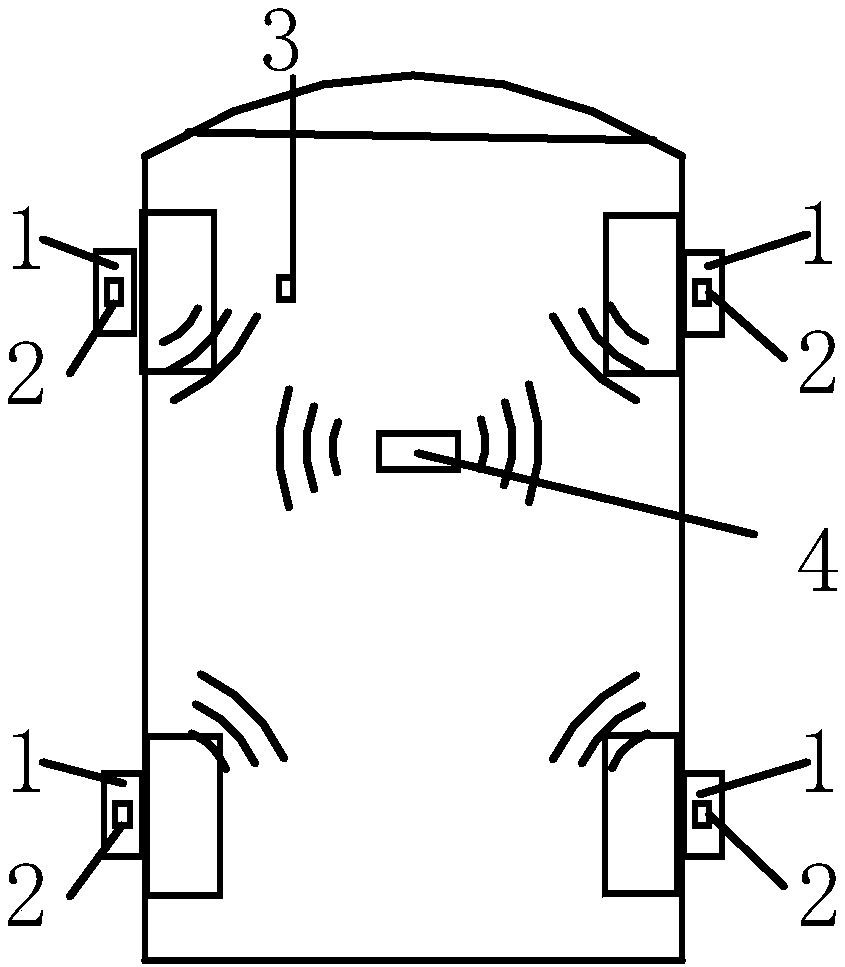

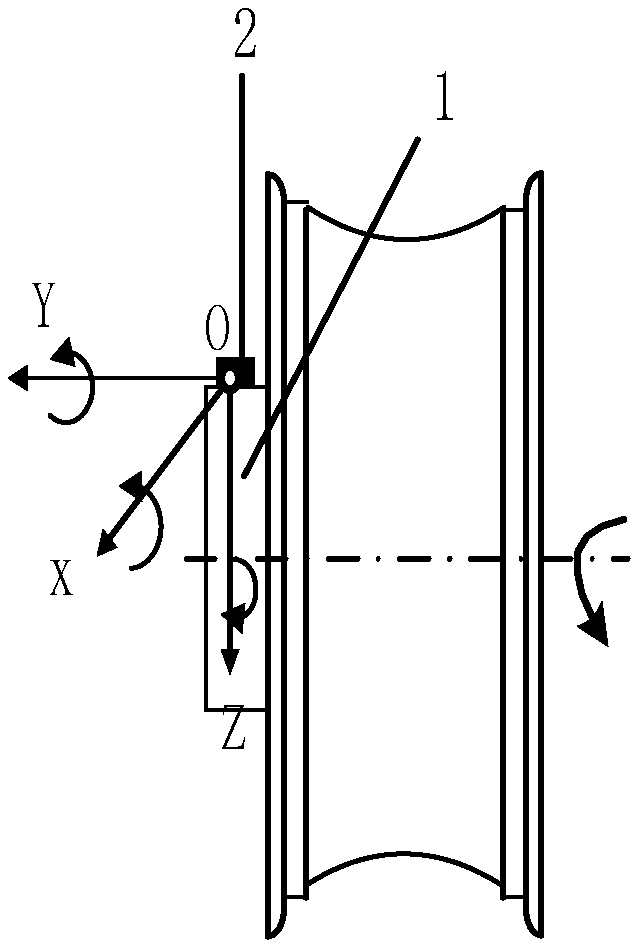

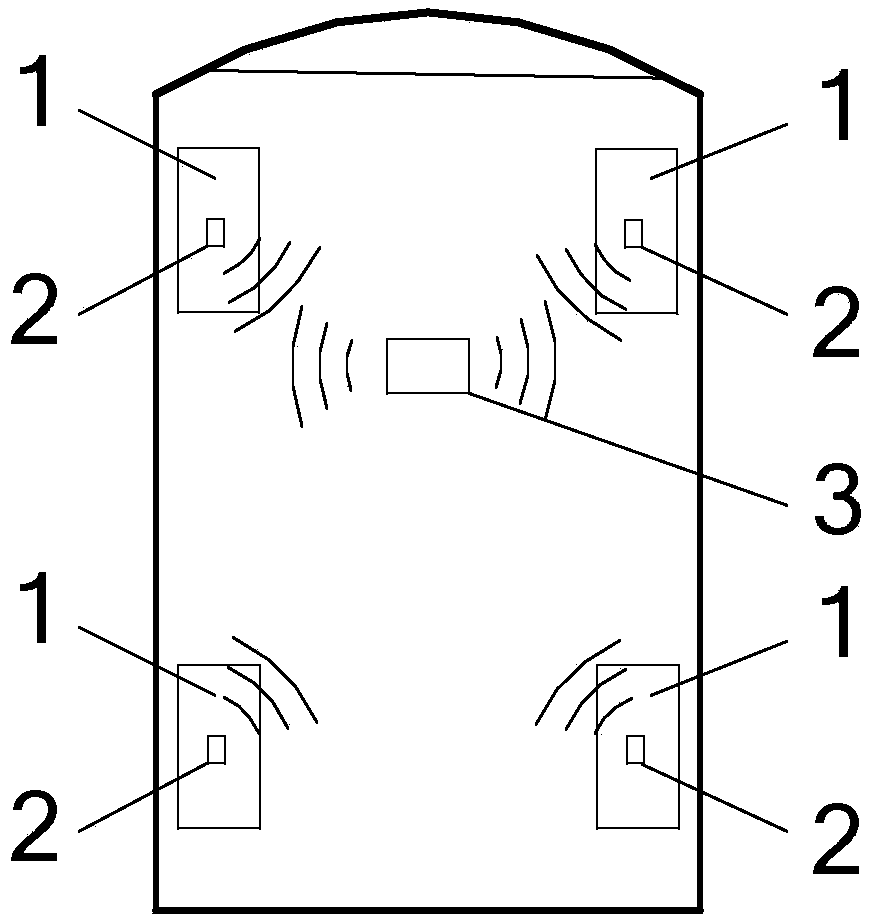

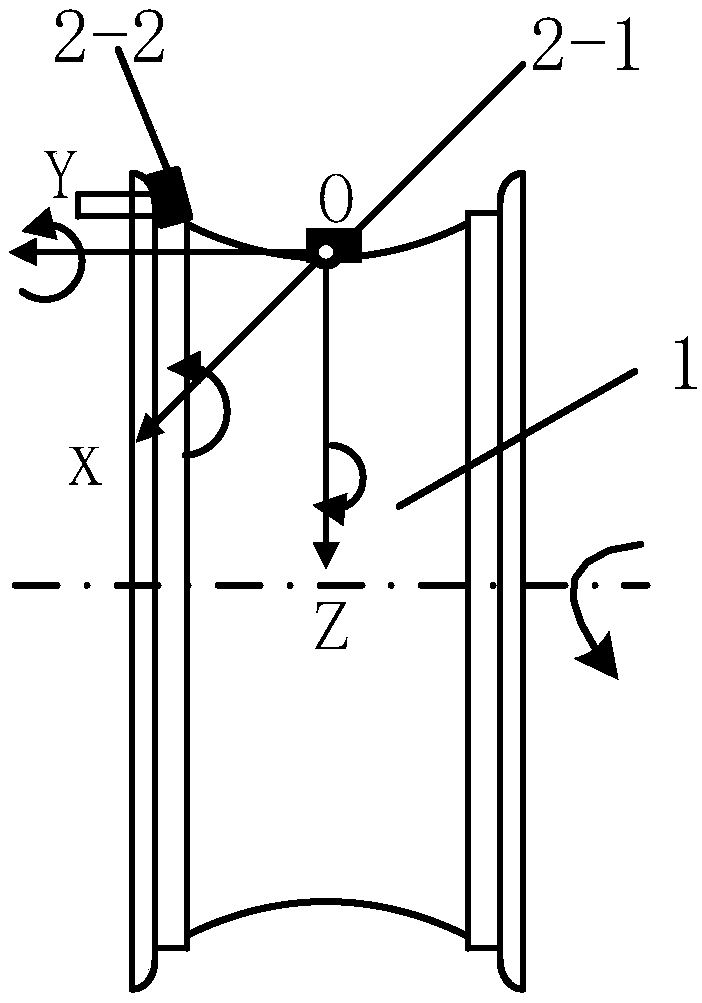

Portable dynamic detection method and system for braking performance of automobile wheels

InactiveCN107727415AAvoid traffic accidentsReduce traffic accidentsVehicle wheel testingIn vehicleAutomotive engineering

The invention discloses a portable dynamic detection method and system for braking performance of automobile wheels. The method comprises steps as follows: three-dimension acceleration of the wheels is sensed by triaxial accelerometers of wheel testing modules, and a braking detection signal is sensed by a pedal force sensor; the signal is output by a wheel tangential acceleration sensor, wheel signal characteristic quantity is extracted through wavelet transformation noise reduction treatment and short-time Fourier transform operation, and rotating period, rotating frequency and angular velocity of the wheels are obtained; braking distance, speed and initial braking speed of an automobile body as well as wheel braking deceleration are calculated according to angular velocity parameters ofthe wheels; inequality of braking deceleration balance of the left and right wheels is calculated according to wheel braking deceleration parameters; MFDD (mean fully developed braking deceleration)is calculated according to initial baking spedd and braking distance parameters of the automobile body; braking coordination time is calculated according to the braking detection signal and MFDD parameters. The system comprises the wheel detection modules, round movable hub catch plates, the pedal force sensor and an in-vehicle central control module.

Owner:FOSHAN NANHAI HONGSHENG VEHICLE INSPECTION EQUIP

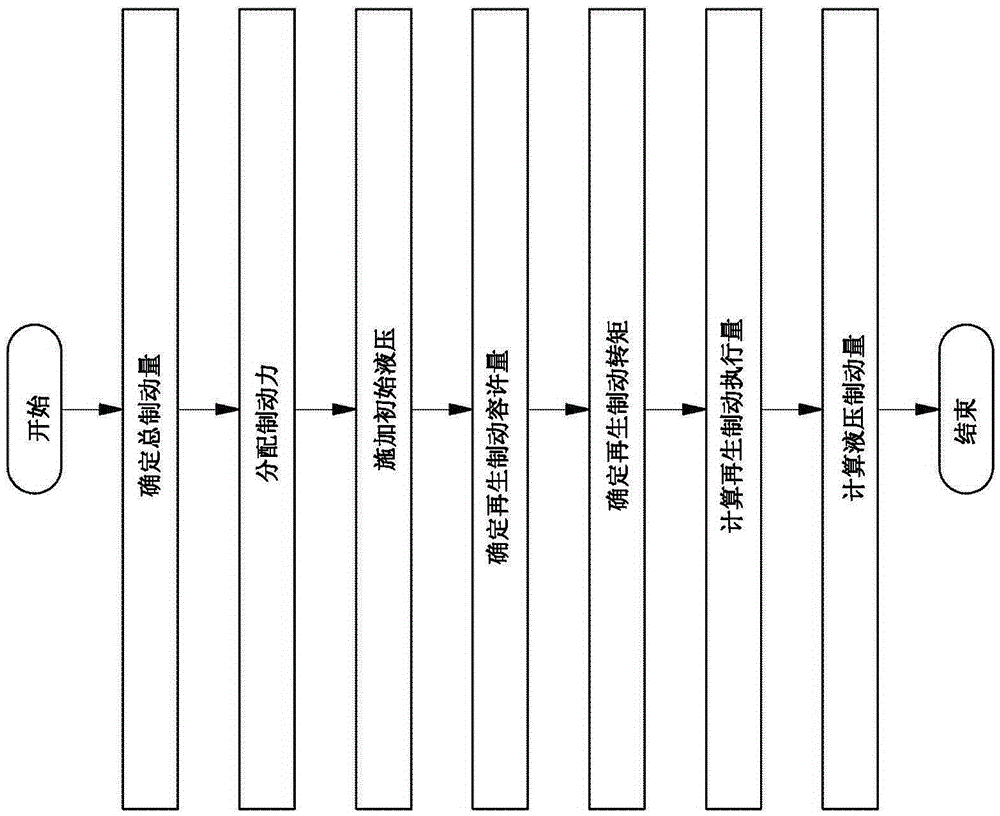

Method for determining amount of regenerative braking

ActiveCN105584373AEnsure braking stabilityMaximize the amount of regenerative brakingHybrid vehiclesSpeed controllerRegenerative brakeMotor torque

Owner:HYUNDAI MOTOR CO LTD +1

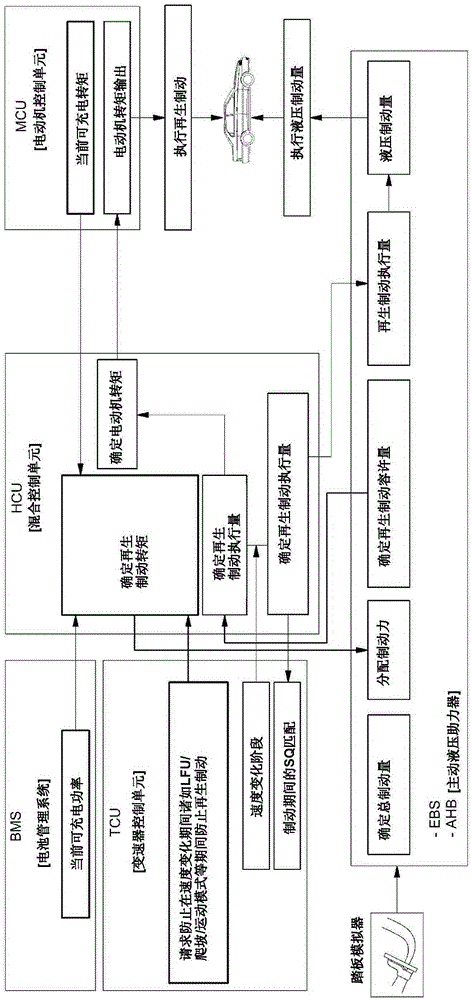

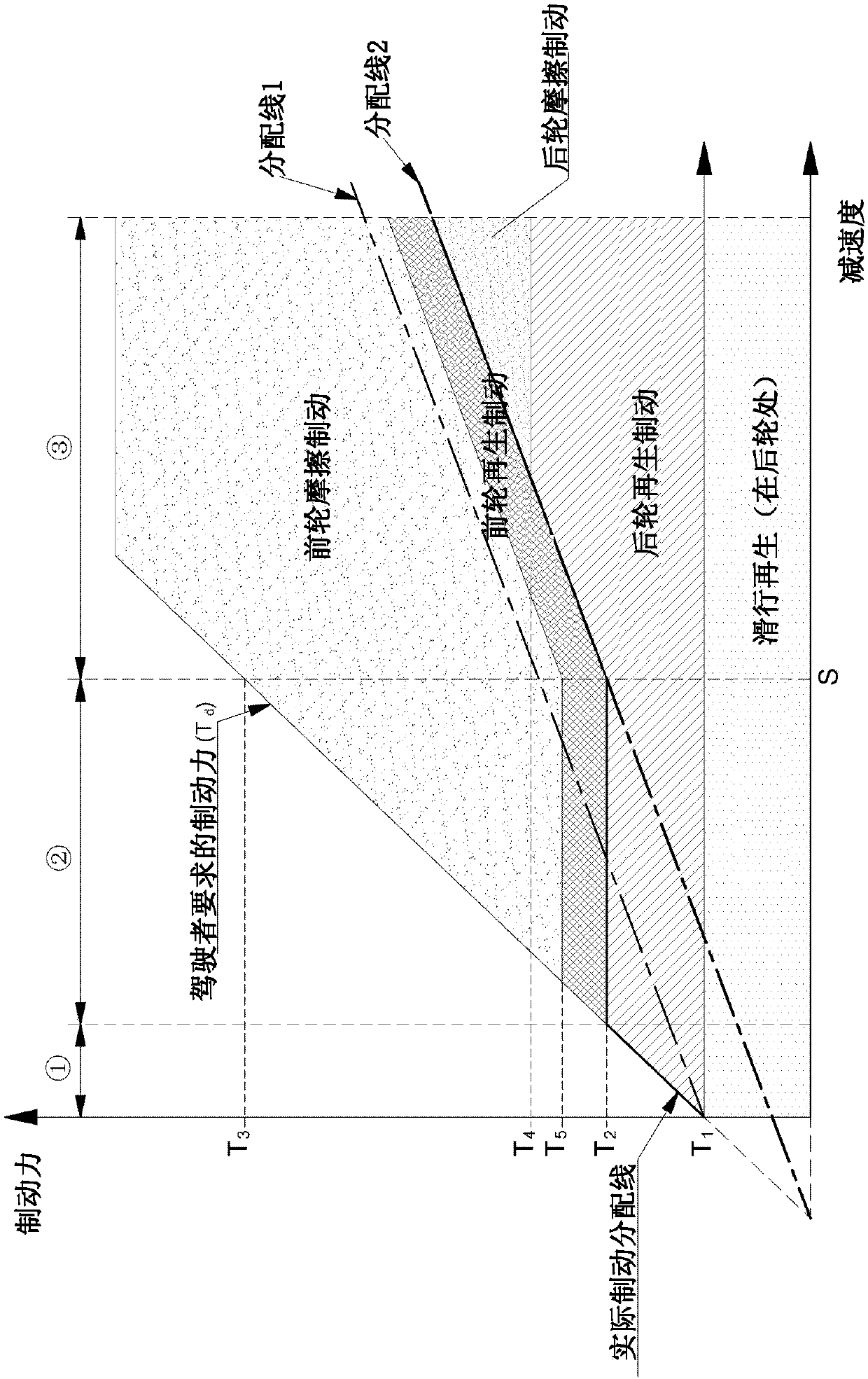

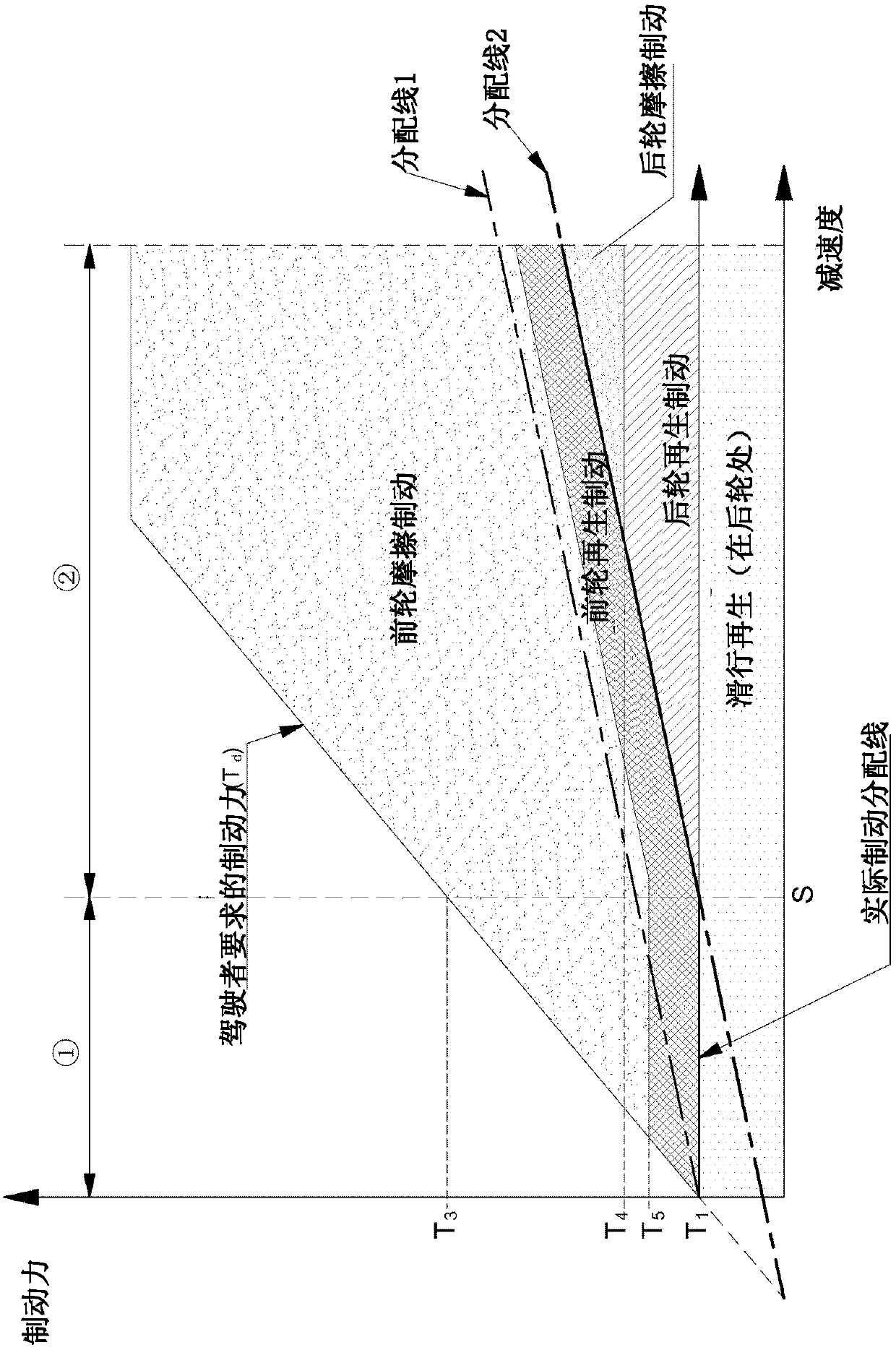

Method for controlling braking force in regenerative brake cooperation control system

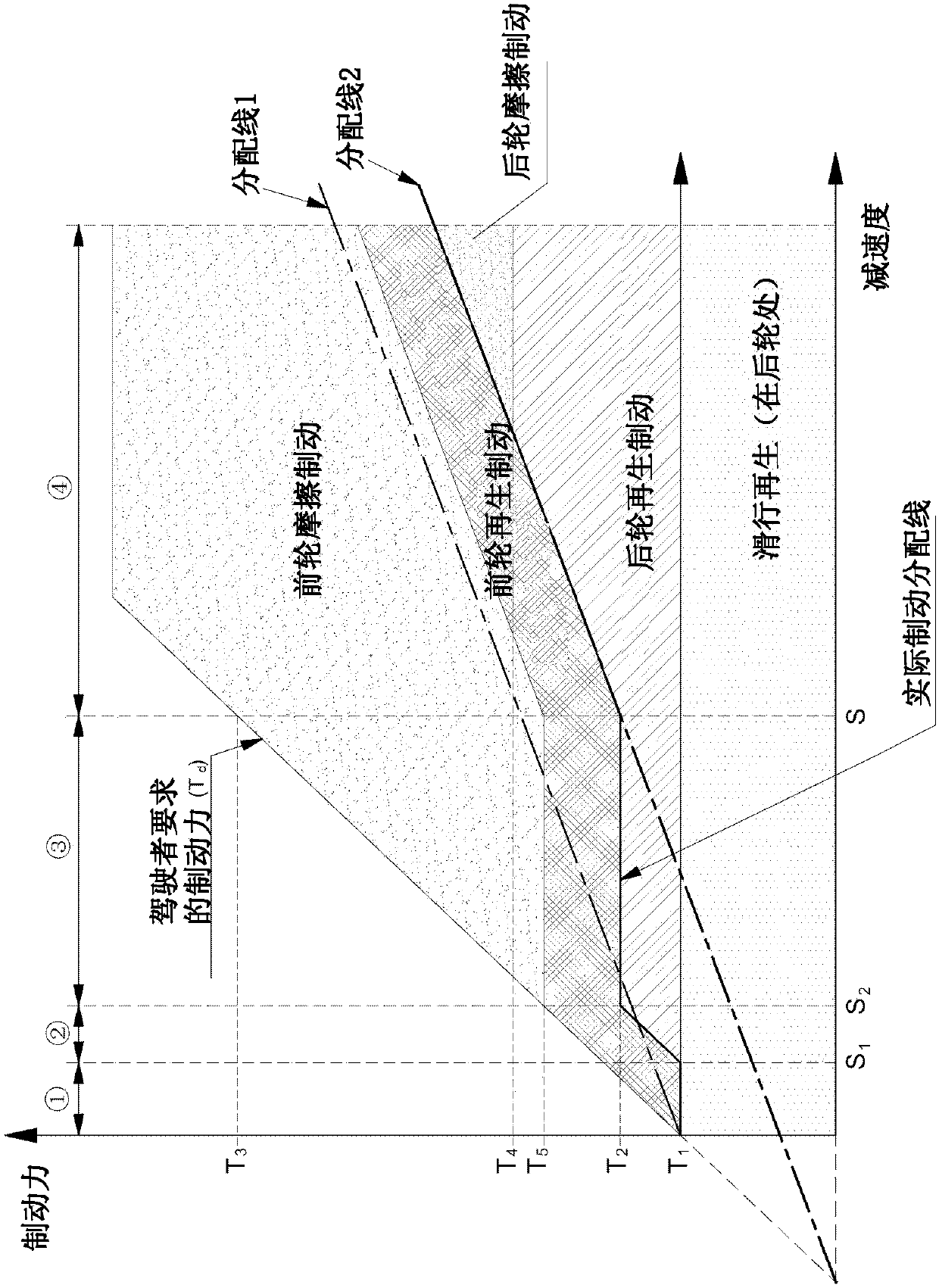

ActiveCN107867185AIncreased regenerative braking forceIncrease frictional braking forceSpeed controllerBraking element arrangementsRegenerative brakeControl system

The invention relates to a method for controlling braking force in a regenerative brake cooperation control system. The method can maximally use regenerative braking force of a rear wheel simultaneously while improving vehicular braking stability by preventing the rear wheel from being locked earlier than a front wheel. The method includes controlling braking forces of the front wheel and the rearwheel by considering a distribution of total vehicular braking force including a coasting regenerative braking force in the regenerative brake cooperation control system in an eco-friendly vehicle which can perform regenerative braking in the rear wheel or both the front wheel and the rear wheel.

Owner:HYUNDAI MOTOR CO LTD

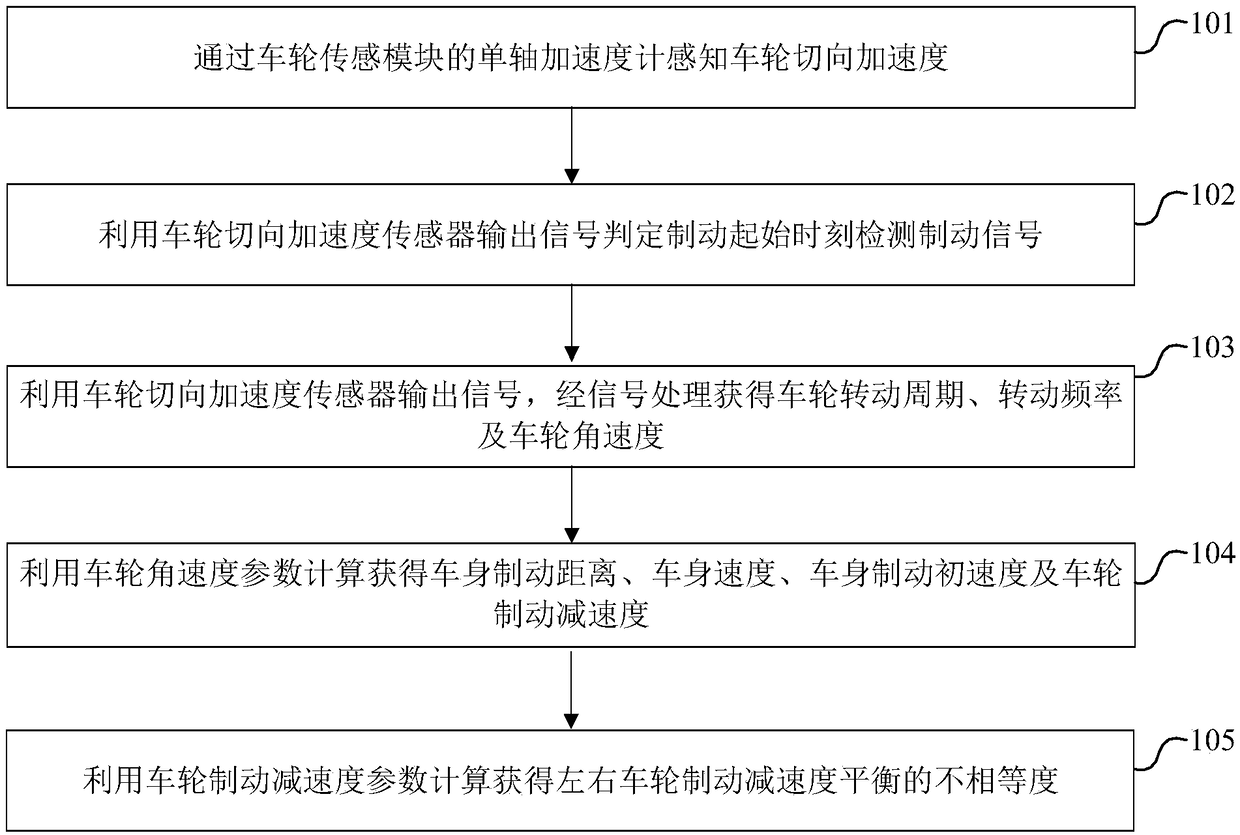

Dynamic monitoring method and system for braking performance of automobile wheel

InactiveCN108871810AOverall Braking EvaluationMany detection parametersVehicle wheel testingStart timeAccelerometer

The invention discloses a dynamic monitoring method for a braking performance of an automobile wheel, and the method comprises the steps: sensing a tangential acceleration of the wheel through a single-axis accelerometer of a wheel sensing module; determining a braking start time by using an output signal of a wheel tangential acceleration sensor, and detecting a braking signal; using the wheel tangential acceleration sensor to output a signal, and processing the signal to obtain the rotation period, rotation frequency and angular speed of the wheel; calculating the braking distance, speed, braking initial speed and braking deceleration of a vehicle body through using the angular velocity parameter of the wheel; calculating the unequality of the brake deceleration balance of the left and right wheels through the braking deceleration parameter of the wheel. The system includes a wheel sensing module and an in-vehicle central control module.

Owner:GUANGDONG POLYTECHNIC OF IND & COMMERCE

A control method for automobile electronic braking force distribution

ActiveCN103661334BGuaranteed timingIncreased braking potentialBraking systemsDistribution controlControl manner

The invention relates to a control method for electronic brake-force distribution of an automobile. The control method includes the first step of setting an EBD subsystem in a general ABS control system, wherein the EBD subsystem comprises an EBD activation trigger and judgment module, an EBD and ABS coordination control module and an EBD control logic module, the second step of determining whether functions of the EBD subsystem need to be activated in the EBD activation trigger and judgment module, the third step of determining the best trigger time of movement of an EBD after the functions are activated, the fourth step of controlling the EBD subsystem to execute corresponding movement according to ABS conditions, detected by the EBD and ABS coordination control module, of front wheels and rear wheels after the movement of the EBD is triggered, and the fifth step of determining whether to enter the EBD control logic module, wherein the EBD control logic module sets the threshold value of critical slip ratio difference values to control the rear wheels to achieve circulating brake control over switching of pressurization, pressure maintenance and pressure reduction through the adoption of a logic threshold value control method based on slip ratio control, and controls brake force over the rear wheels through the adoption of the method combining time constant control and liquid inlet valve opening control. The control method for electronic brake-force distribution of the automobile can be widely applied to the automobile braking process.

Owner:BEIJING WONDER CAREWAY AUTOMOTIVE TECH

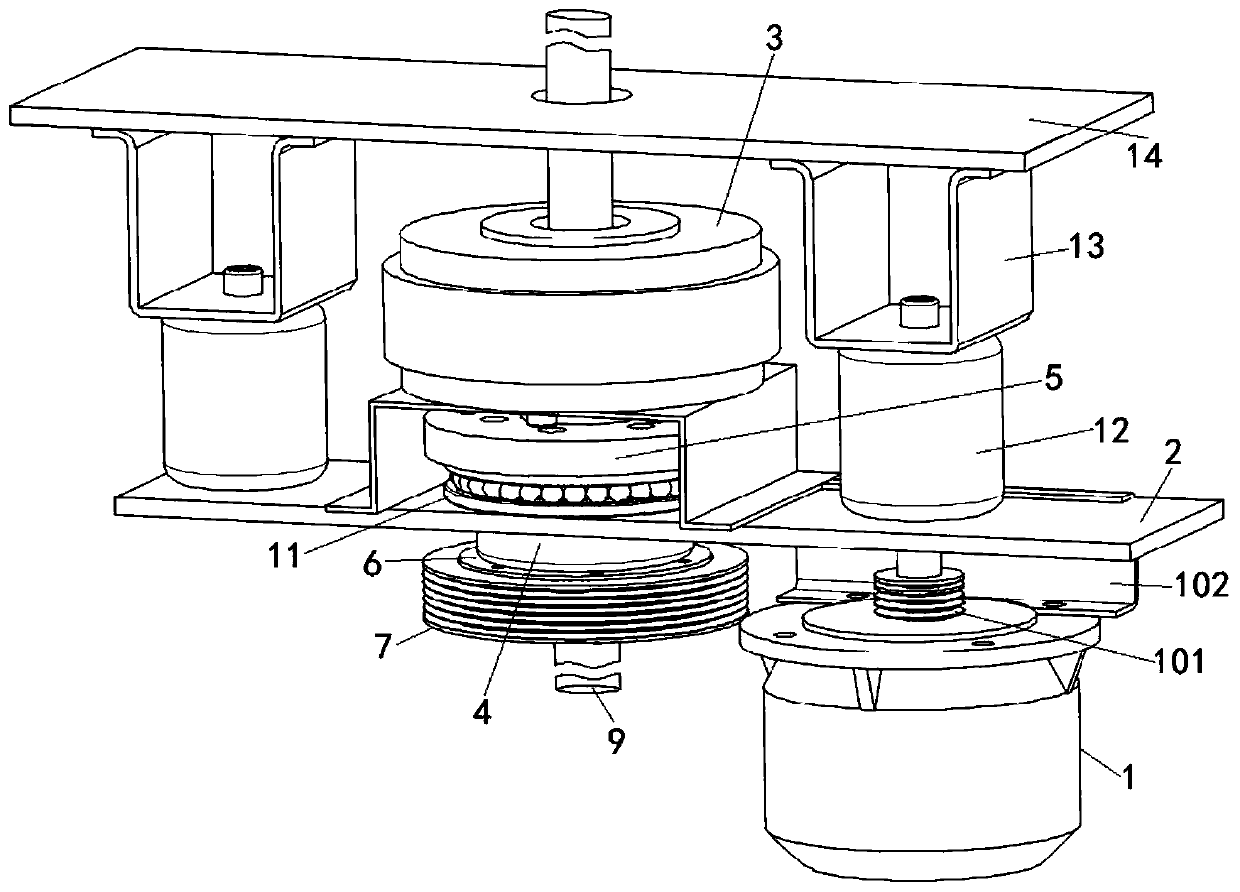

Magnetorheological fluid brake

ActiveCN109505895ALow calorific valueEnsure braking stabilityLiquid resistance brakesBrake actuating mechanismsNew energyMagnetorheological fluid

The invention discloses a magnetorheological fluid brake, and relates to the technical field of magnetorheological fluid brakes. A braking function is realized by retractable brake blades disposed between a left brake disc and a right brake disc, during braking, after the brake blades extend out from brake blade temporary storage slots, the gap between the left brake disc and the right brake discis small, and a magnetic field generated by an electromagnetic coil quickly realizes the braking function. The left brake disc and the right brake disc and a left end cover and a right end cover are provided with large gaps, the viscous resistance in the zero field is small, the heat productivity of the magnetorheological fluid brake during the running of a vehicle is low, the energy loss is reduced, and the braking stability of the magnetorheological fluid brake is further effectively ensured; separating from a hydraulic system, the instantaneous attraction of an electromagnet and the restoring force of a tension spring are counted on to regulate the pop-up and contraction of the brake blades, the decoupling of the magnetorheological fluid brake and a brake pedal is realized, and the realization of brake-by-wire on a new energy vehicle is facilitated.

Owner:HEFEI UNIV OF TECH

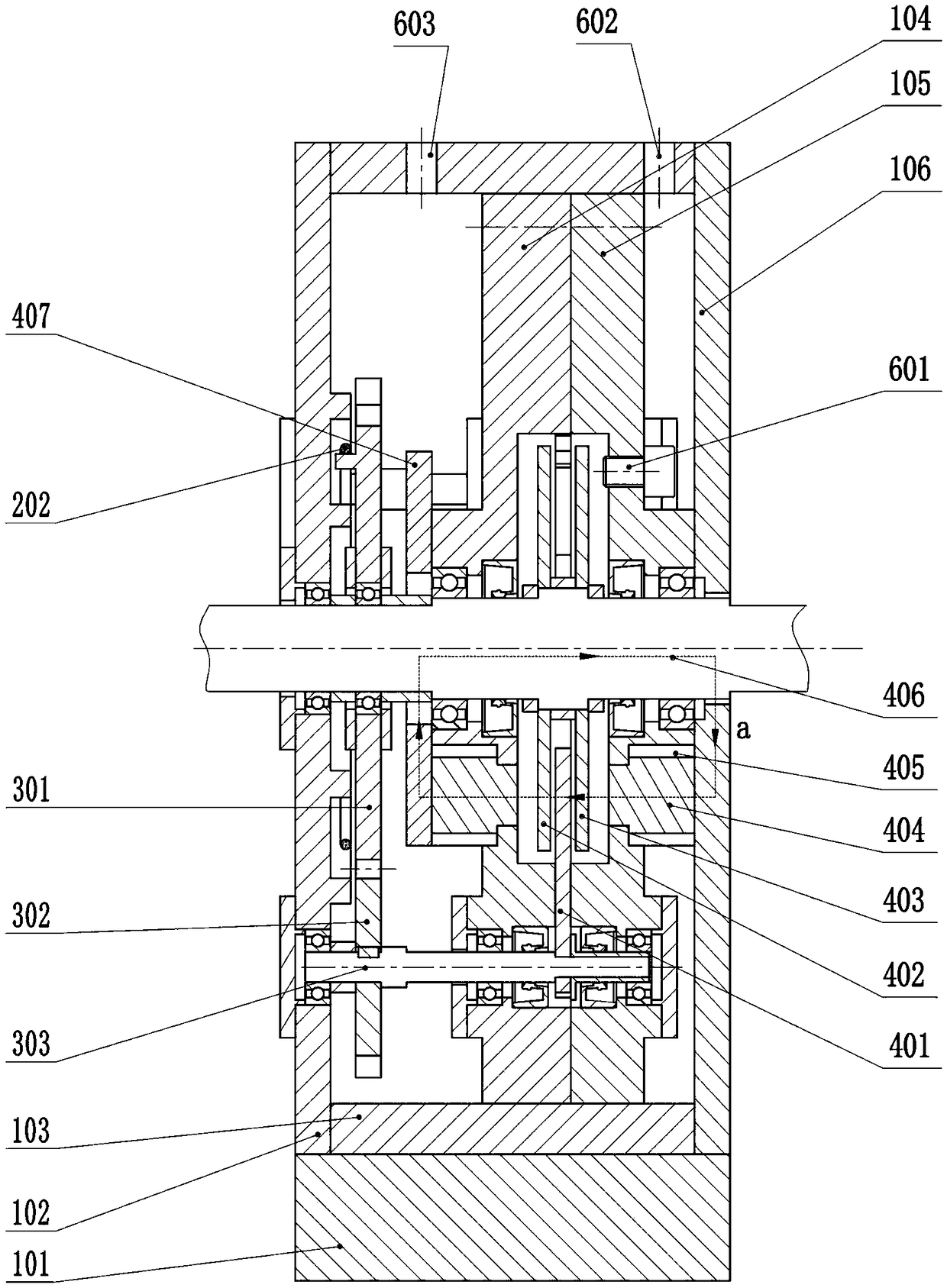

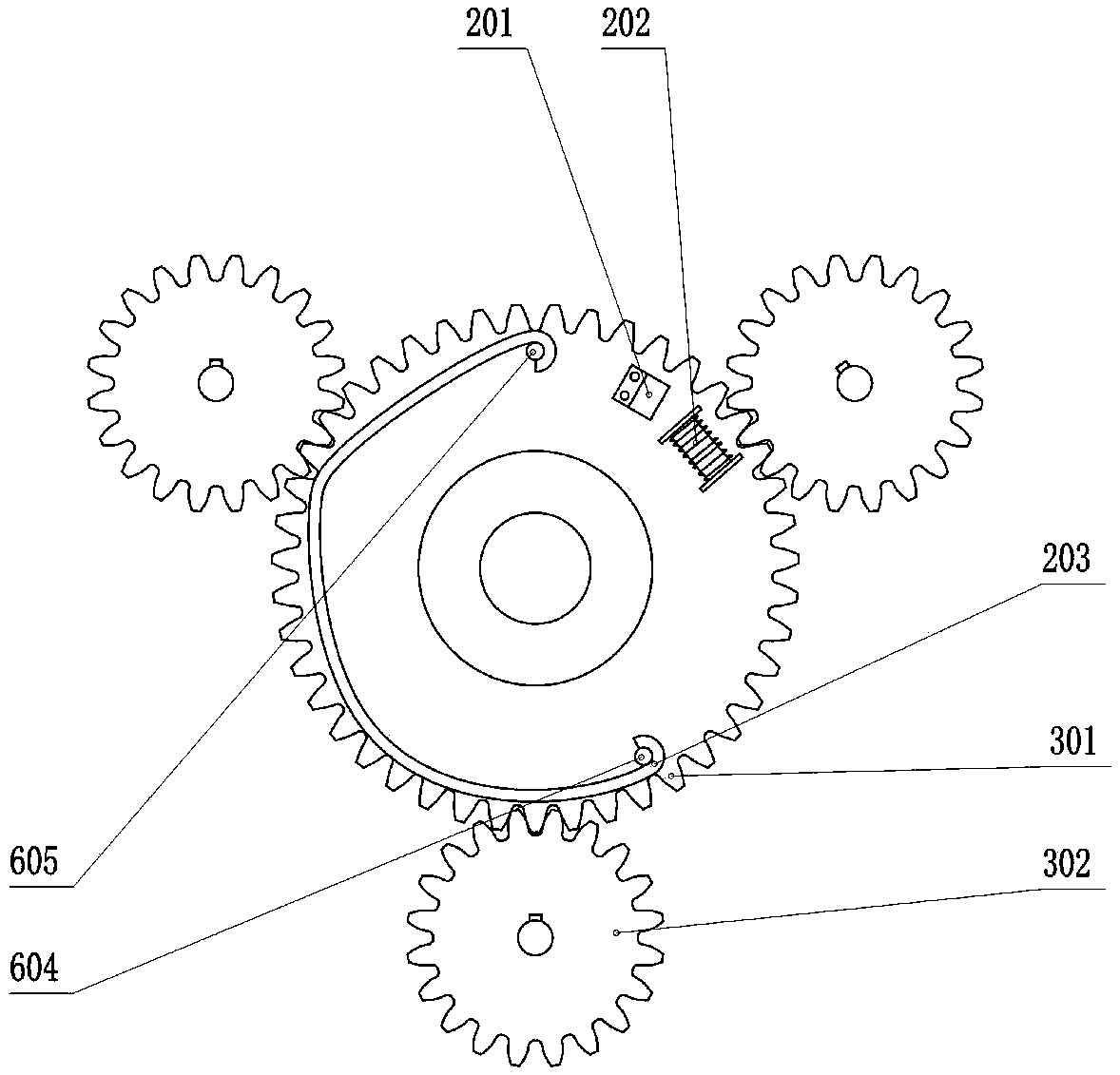

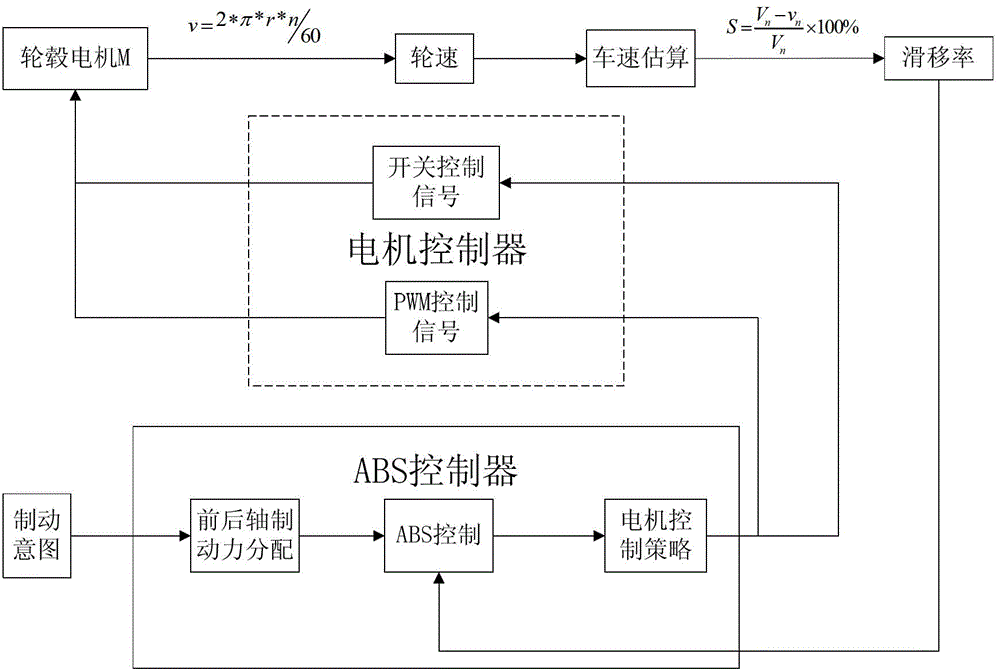

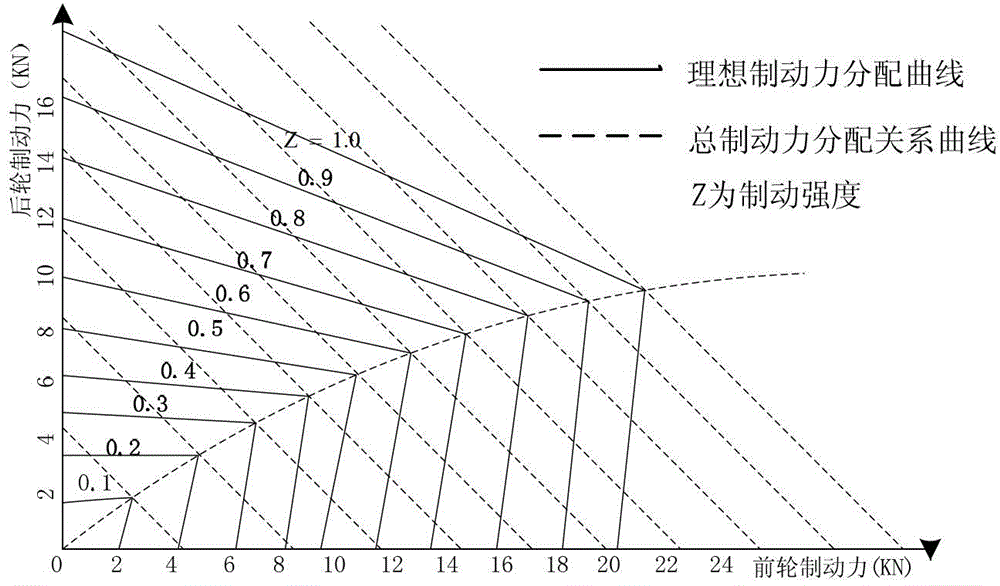

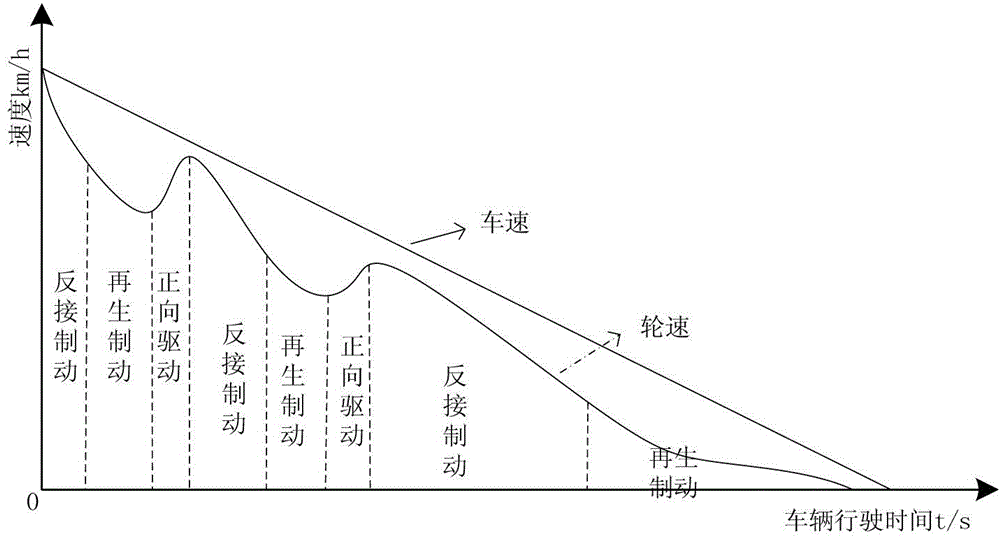

Method for controlling anti-lock system of four-hub-motor drive electric car free of hydraulic braking

The invention discloses a method for controlling an anti-lock system of a four-hub-motor drive electric car free of hydraulic braking, and relates to the field of automotive electronic control. In each control stage, braking force distribution of a front axle and a rear axle of a vehicle and reverse braking, regenerative braking, reverse-regenerative coordinating braking and forward driving of an in-wheel-motor are related. A logic threshold control method is adopted in ABS control, the slip rate (S) is compared with a set threshold value, the value and the direction of input voltage of the motor are controlled so that the forward driving, the reverse braking and the regenerative braking of the motor can be achieved, and accordingly wheel lock is prevented. The slip rate of a wheel is controlled near a theoretical value, the ground attachment coefficient is utilized to the maximum extent, and safe braking is achieved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

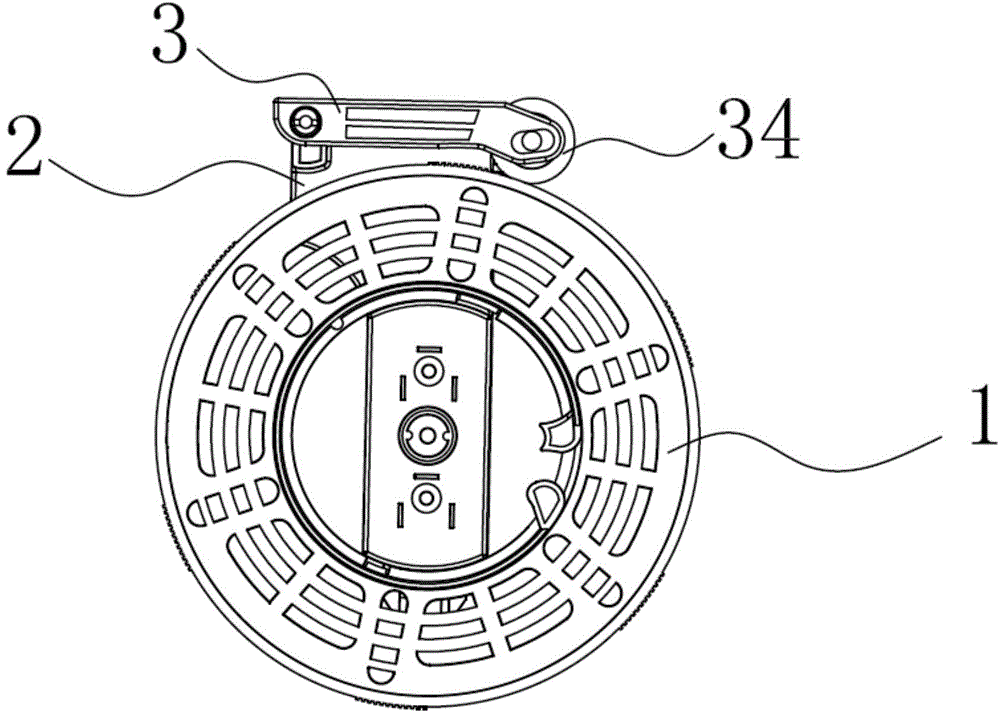

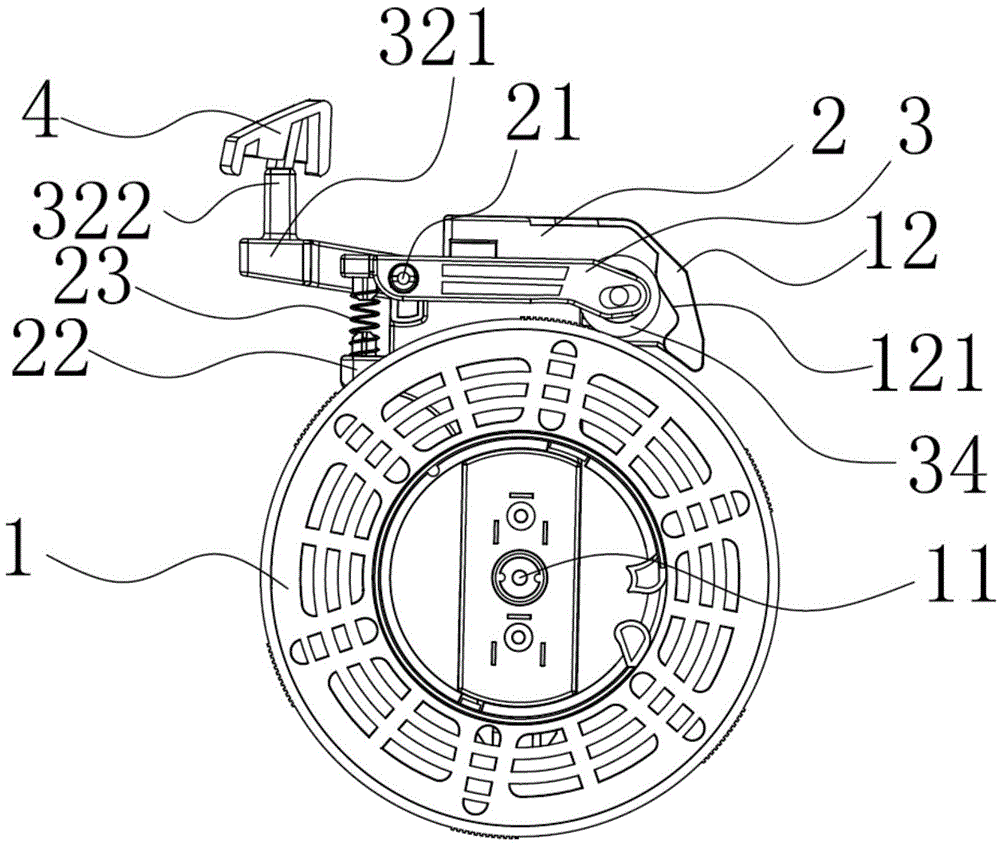

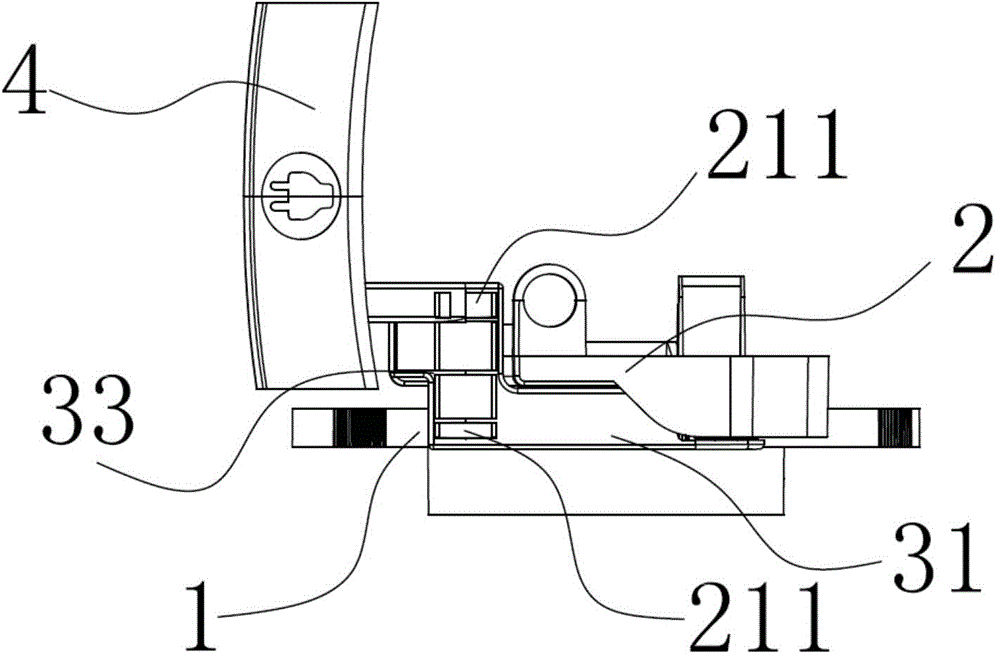

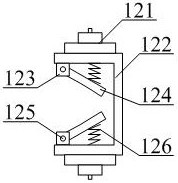

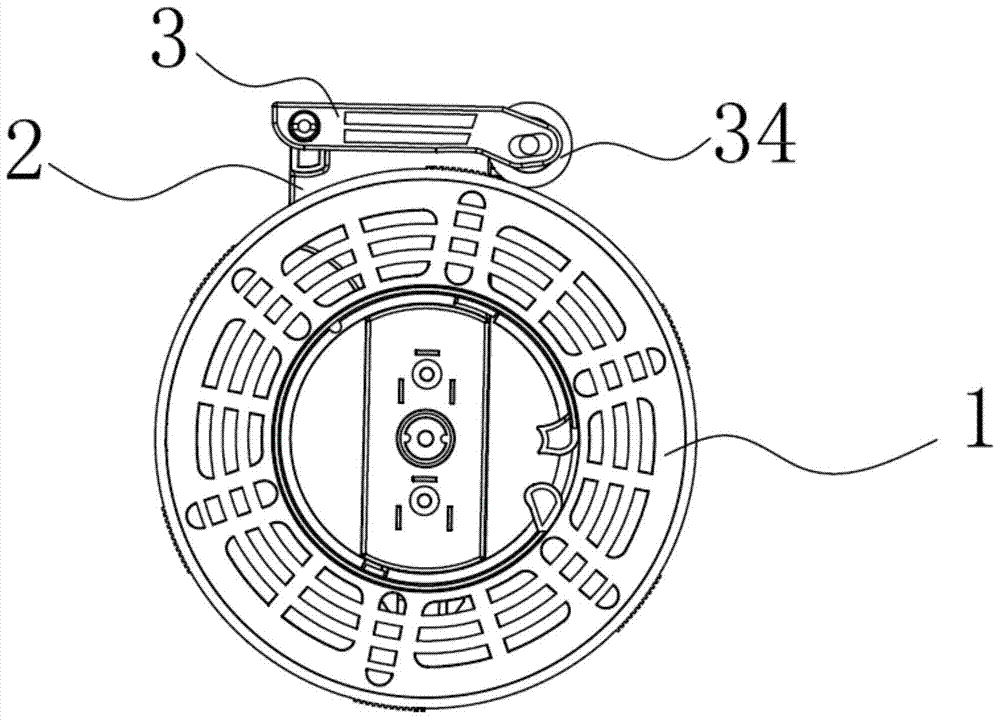

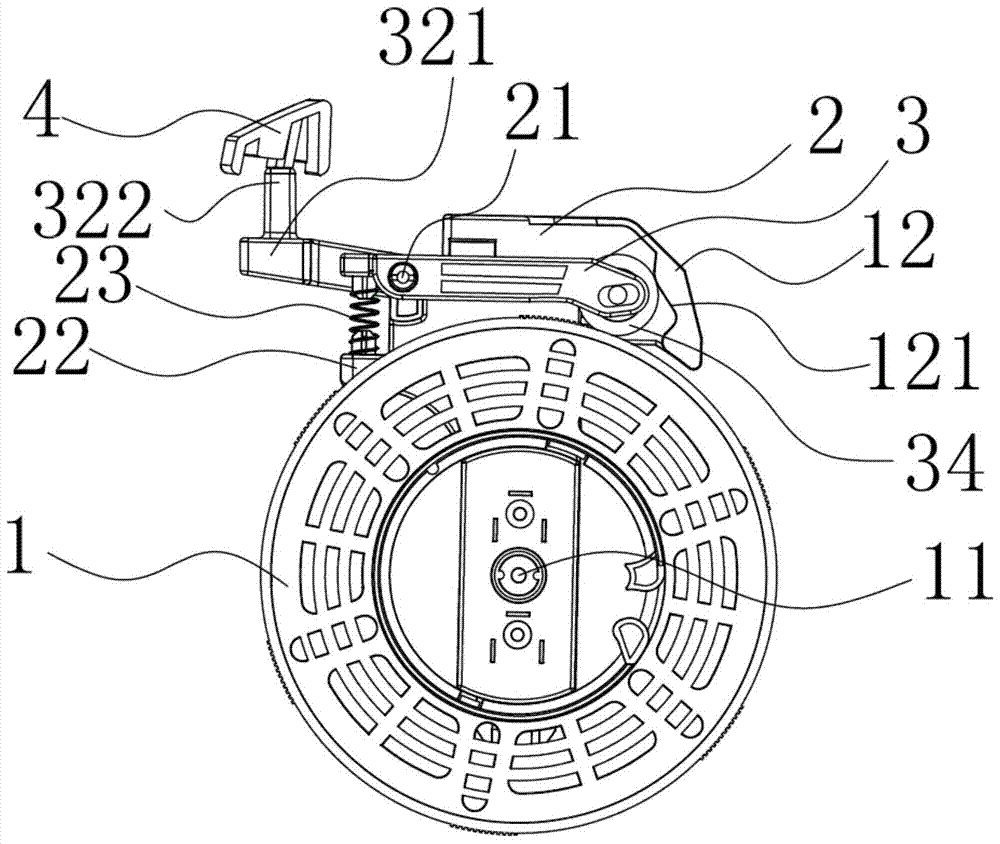

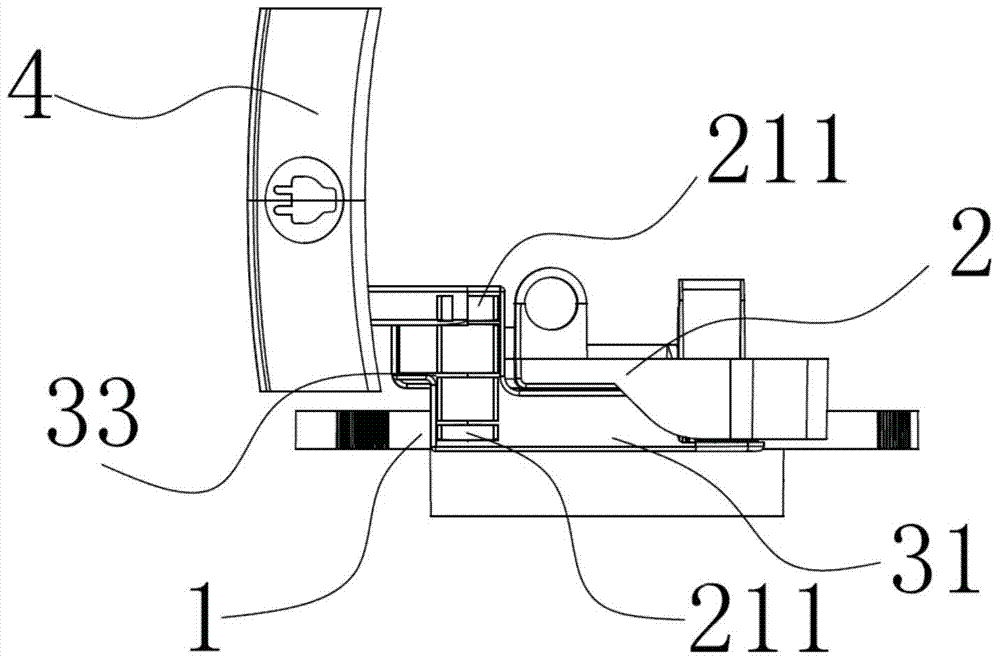

Dust collector tension pulley frame dislocation balancing structure

The invention discloses a dust collector tension pulley frame dislocation balancing structure, which is arranged on a winding roll, and comprises a tension pulley frame support and a tension pulley frame, wherein the tension pulley frame support is rotatably connected on a rotating shaft of the winding roll, a shaft body is arranged on the tension pulley frame support in the transverse direction, first connecting portions are formed on the two end portions of the tension pulley frame support, the tension pulley frame comprises a first frame unit and a second frame unit which are arranged in a dislocation mode, second connecting portions which are corresponding to the first connecting portions are arranged on the two outer sides of a connecting position of the first and the second frame units, the tension pulley frame is rotatably connected on the tension pulley frame support through the first and the second connecting portions, a free end of the first frame unit is rotatably connected with a tension pulley, and a free end of the second frame unit is used as a point of application. Compared with the prior art, the dust collector tension pulley frame dislocation balancing structure does not need to guarantee the point of application on a center position of the tension pulley frame, and just needs to apply force on the free end of the second frame unit, thereby being capable of effectively overcoming a shift phenomenon of the tension pulley because the point of application shifts a center in the prior art.

Owner:SUZHOU CHUNJU ELECTRIC CO LTD

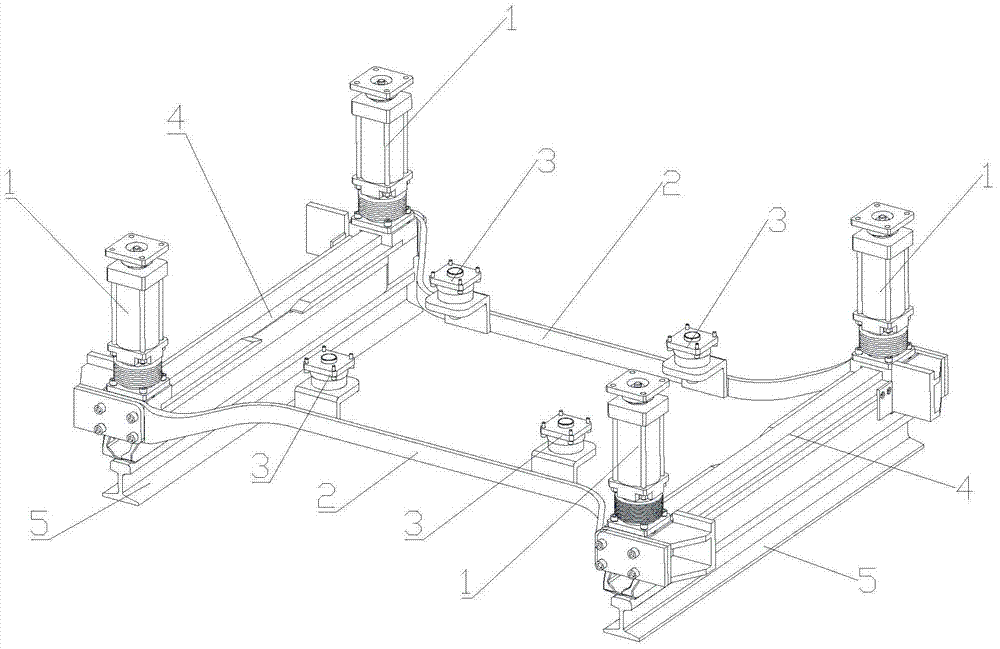

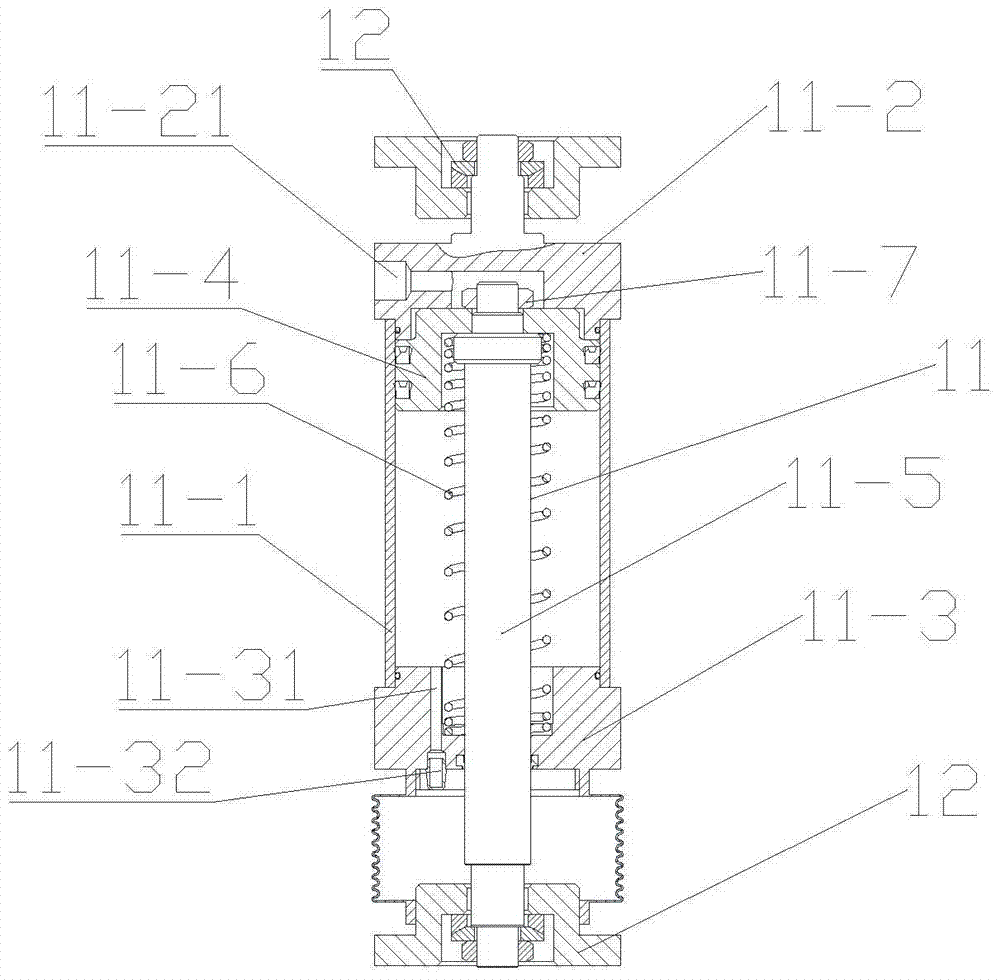

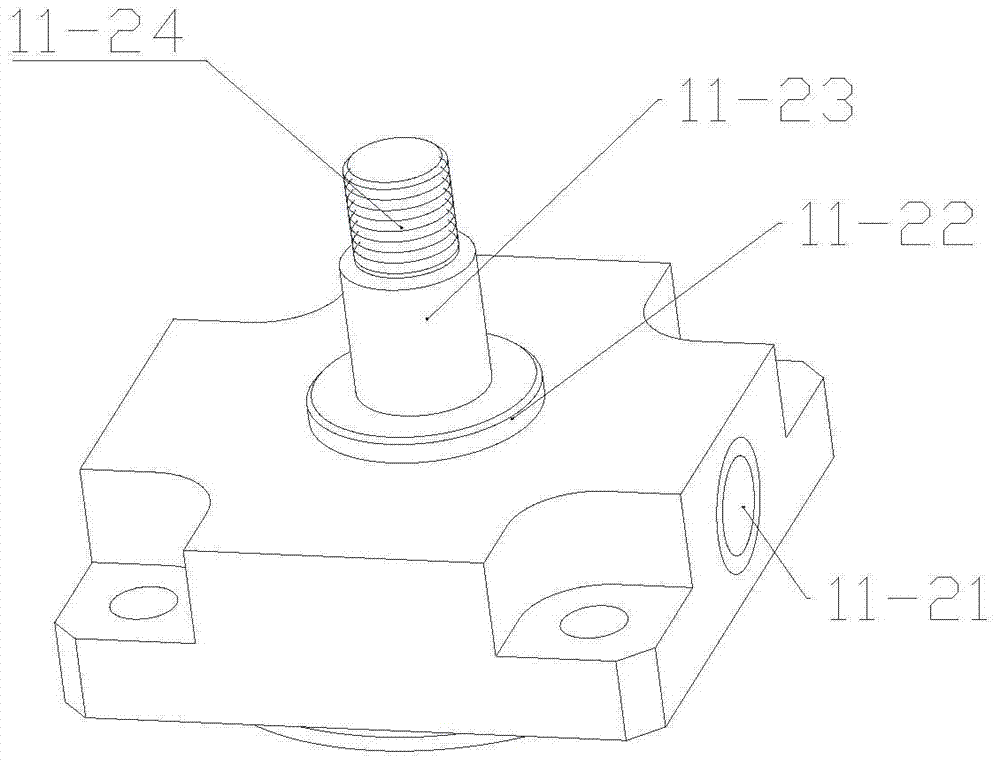

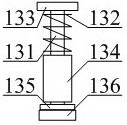

Large Gauge Magnetic Rail Brake Suspension Device for Rail Vehicles

ActiveCN105109515BEnsure braking stabilityEnsure consistencyTrack-braking member co-operationBogieLoss rate

The invention relates to a suspension device for a large-gauge magnetic rail brake of a rail vehicle, which is installed between the magnetic rail brakes on both sides and the vehicle bogie. The suspension device includes a cylinder component, a connecting plate and a positioning component. The cylinder component is installed on each The front and rear ends of the upper surface of the side magnetic rail brake, the upper end of the cylinder is connected to the vehicle bogie, the cylinder consists of a cylinder body and an adapter assembly, the adapter assembly is installed at the upper and lower ends of the cylinder body, and the cylinder body is a single-acting spring cylinder. The transfer assembly is equipped with a matching structure of arc surface and curved surface; the connecting plate is installed horizontally between the magnetic track brakes arranged oppositely on both sides of the vehicle bogie, connecting the magnetic track brakes on both sides as a whole, and the upper and lower ends of the positioning composition are respectively connected with the connecting The plate is fixedly connected to the bottom surface of the vehicle bogie. It can ensure a large gap between the magnetic track brake and the track, and can quickly and reliably apply the magnetic track braking force to reduce the braking force loss rate.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

Lift type driving device for elevator

InactiveCN110482376AEnsure lifting stabilityEnsure braking stabilityBuilding liftsHoisting equipmentsPulleyMagnetic powder

The invention discloses a lift type driving device for an elevator, and relates to the technical field of elevator equipment. The lift type driving device includes a motor, a bearing plate and a magnetic powder brake. An output shaft of the motor is fixedly provided with a driving pulley, and the motor is fixedly installed on the lower surface of the bearing plate through a first connecting plate;a connecting cylinder penetrates through the middle part of the bearing plate, and a first through hole is formed in the connecting cylinder; and a connecting ring is fixedly installed on the top endface of the connecting cylinder, and a second through hole is formed in the connecting ring. According to the lift type driving device, the driven pulley is driven to drive brake shaft sleeves of a step sleeve, the connecting cylinder, the connecting ring and the magnetic powder brake to rotate, so that a screw nut rotates and rises and falls in the axial direction of a screw rod; finally, the brake of the screw nut on the screw rod is realized by controlling the magnetic powder brake; and due to the process, the lifting and falling and brake stability of the elevator driving device are effectively ensured, the risk of people riding is reduced, and the comfort of people riding is improved.

Owner:安徽兴国电子科技有限公司

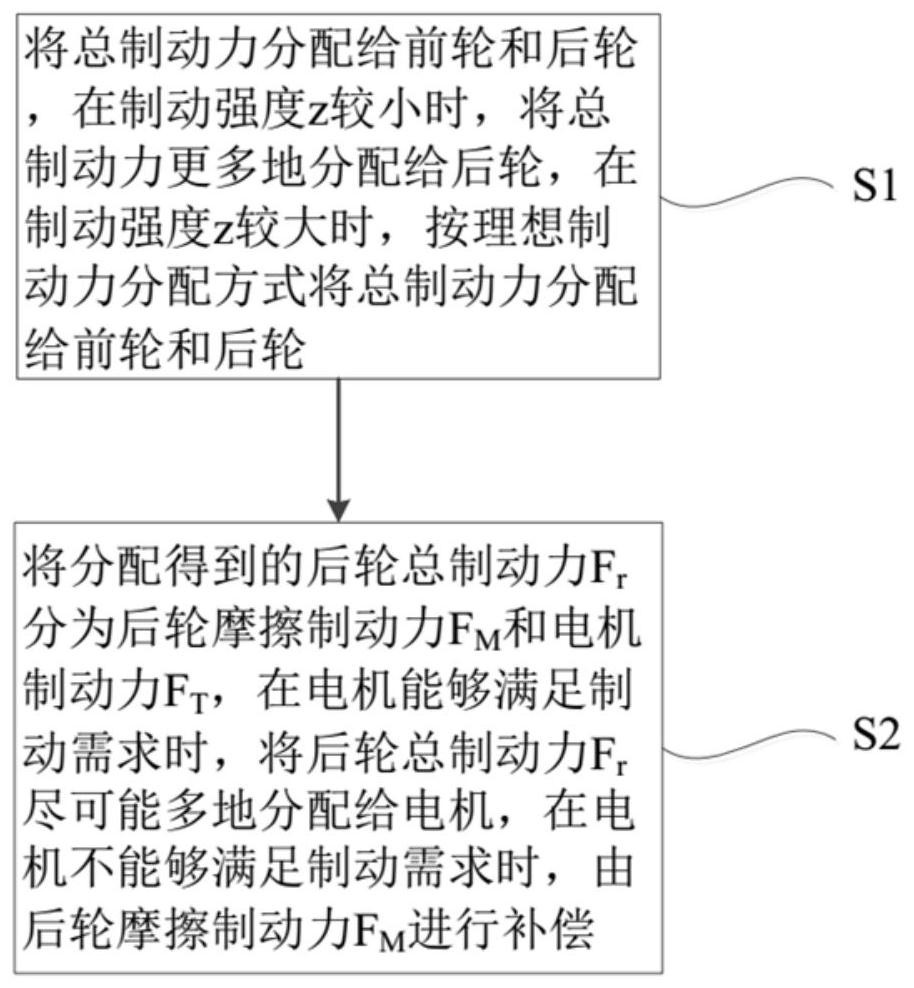

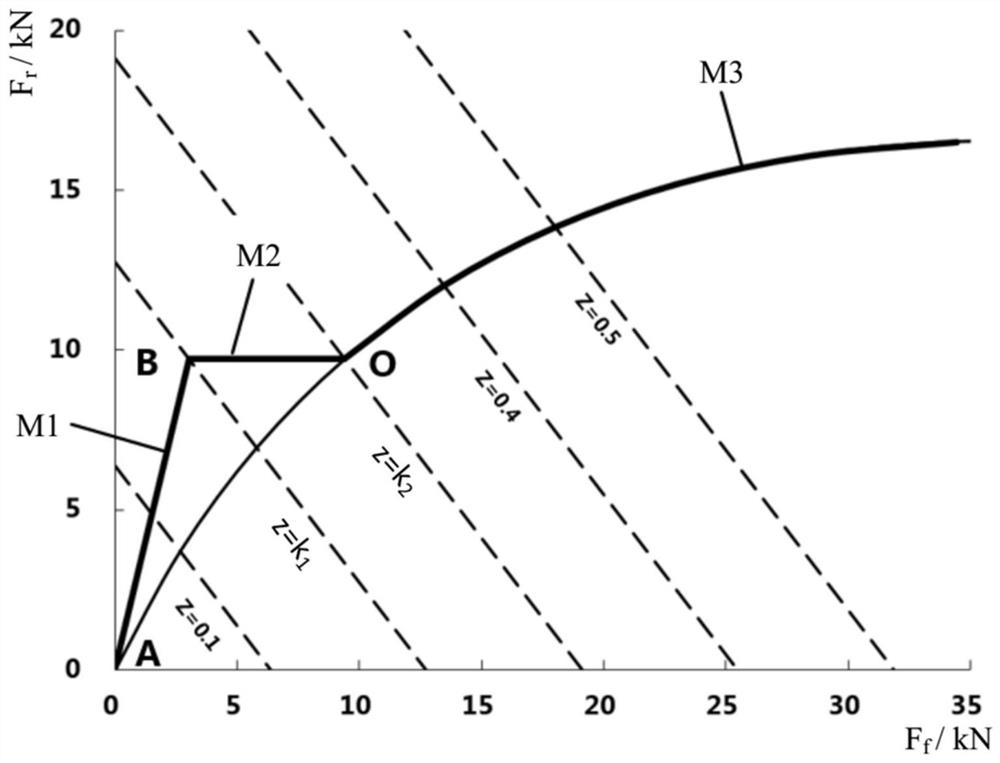

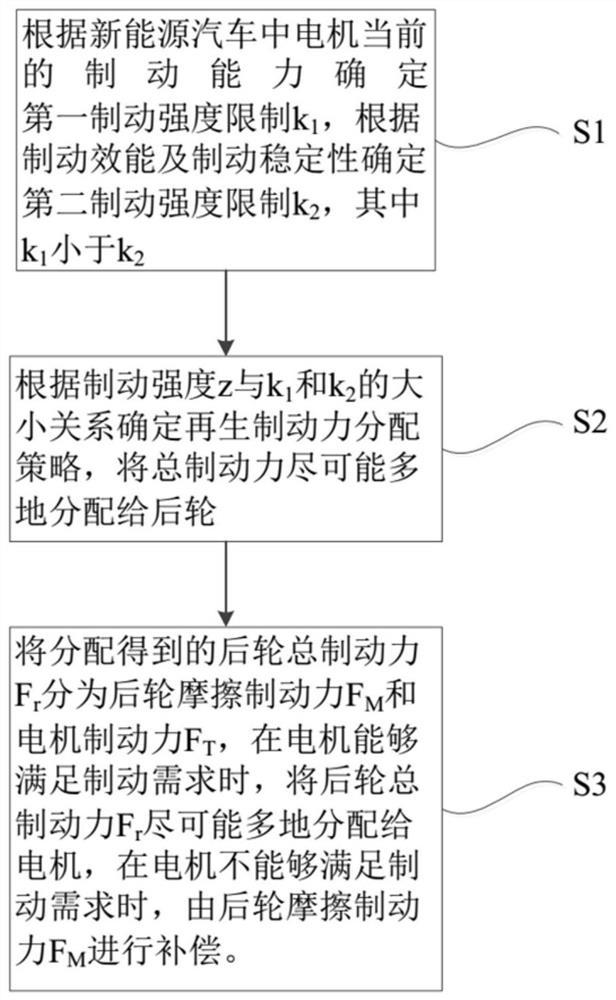

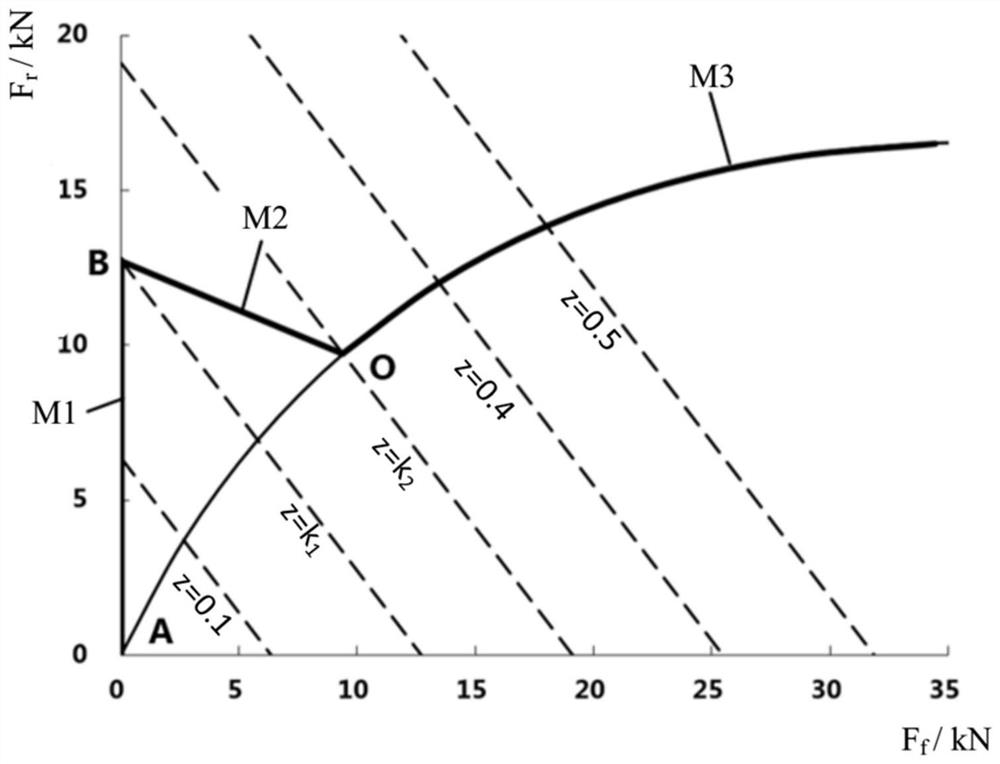

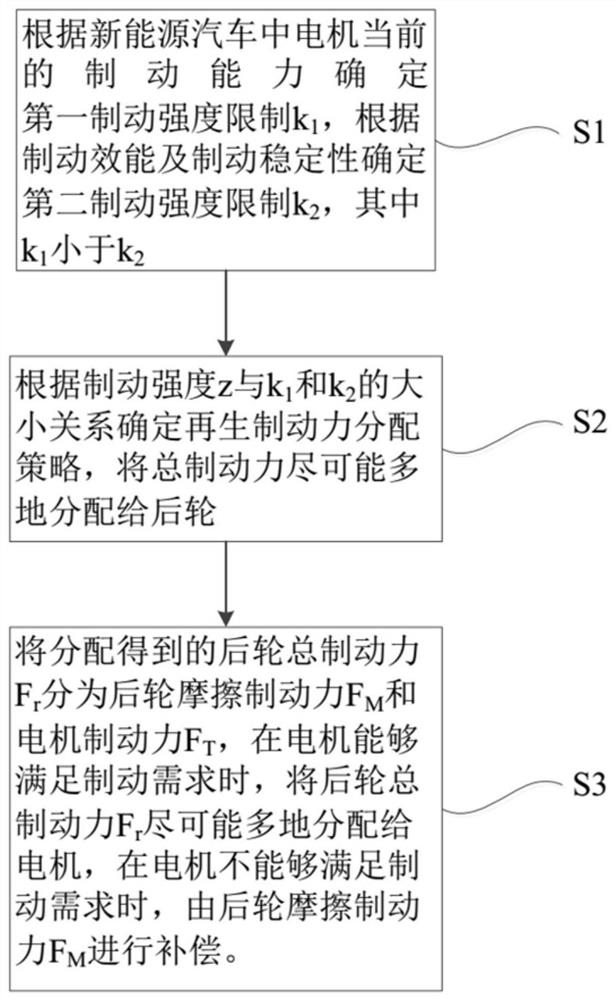

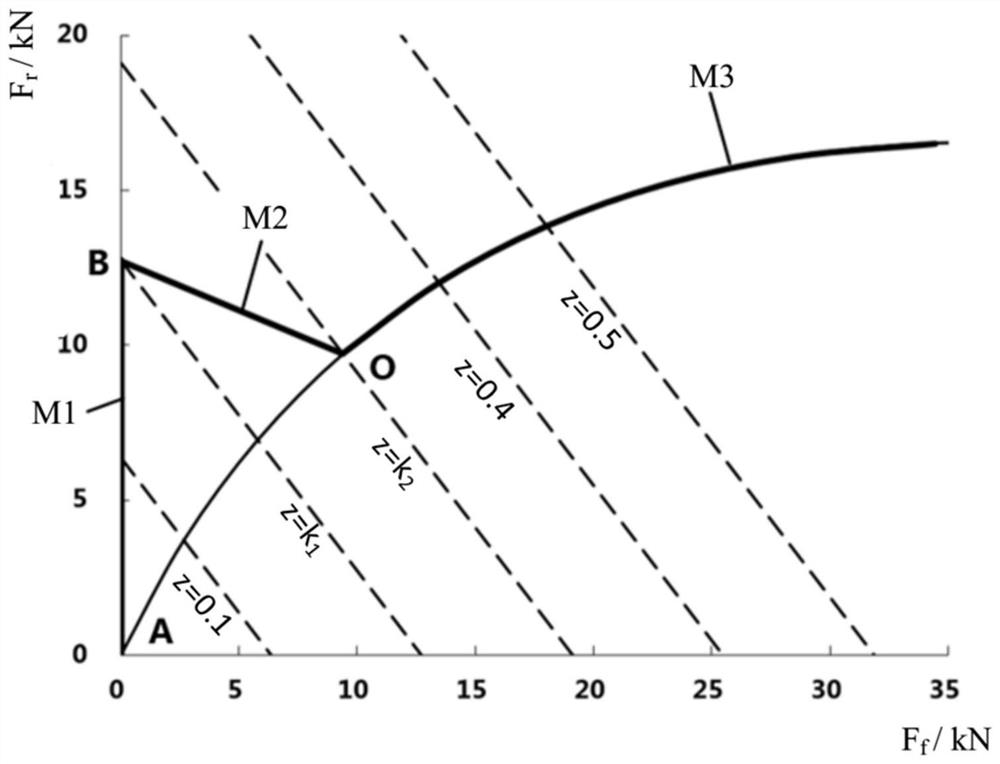

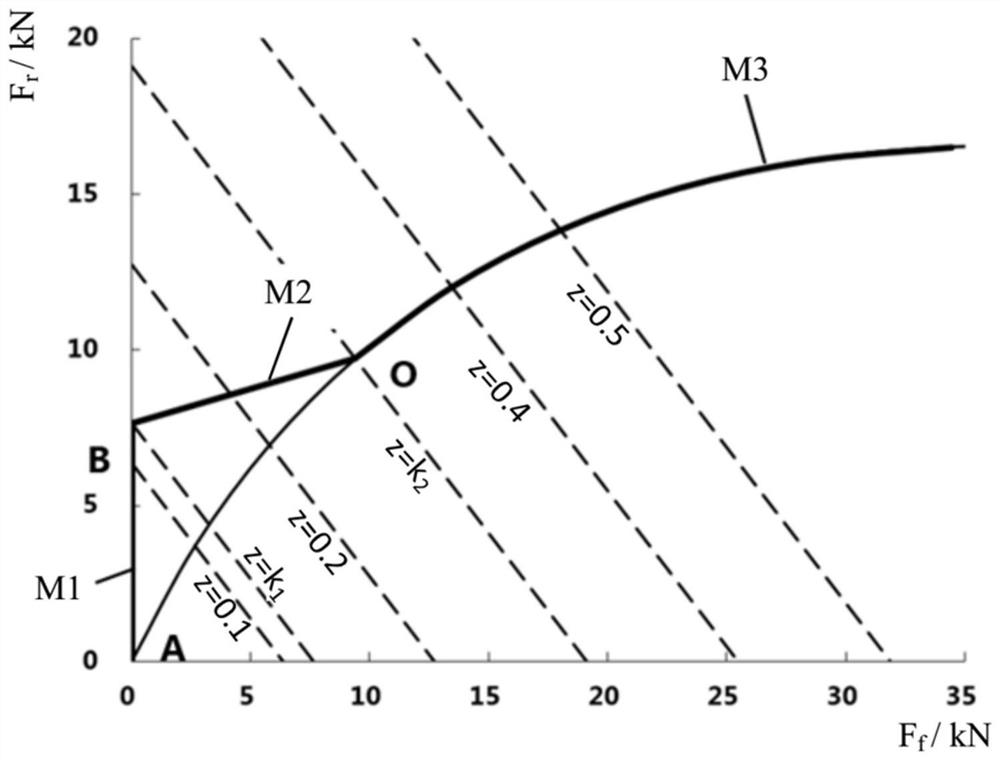

New energy automobile regenerative braking force distribution method and new energy automobile

ActiveCN112477610AEfficient recycling effectGuaranteed braking effectElectrodynamic brake systemsElectric energy managementRegenerative brakeNew energy

The invention discloses a new energy automobile regenerative braking force distribution method and a new energy automobile, and relates to the technical field of new energy automobile braking. The regenerative braking force distribution method for the new energy automobile comprises the steps that the total braking forces are distributed to front wheels and rear wheels, more total braking forces are distributed to the rear wheels when the braking strength is small, and the total braking forces are distributed to the front wheels and the rear wheels according to an ideal braking force distribution mode when the braking strength is large; the rear wheel total braking force obtained through distribution is divided into the rear wheel friction braking force and the motor braking force, when the motor can meet the braking requirement, the rear wheel total braking force is distributed to the motor as much as possible, and when the motor cannot meet the braking requirement, the rear wheel friction braking force is used for compensation. When the regenerative braking force is distributed through the regenerative braking force distribution method for the new energy automobile, the braking capacity of the motor can be brought into full play on the basis that the good braking feeling is guaranteed, and efficient braking energy recovery is achieved.

Owner:FAW JIEFANG AUTOMOTIVE CO

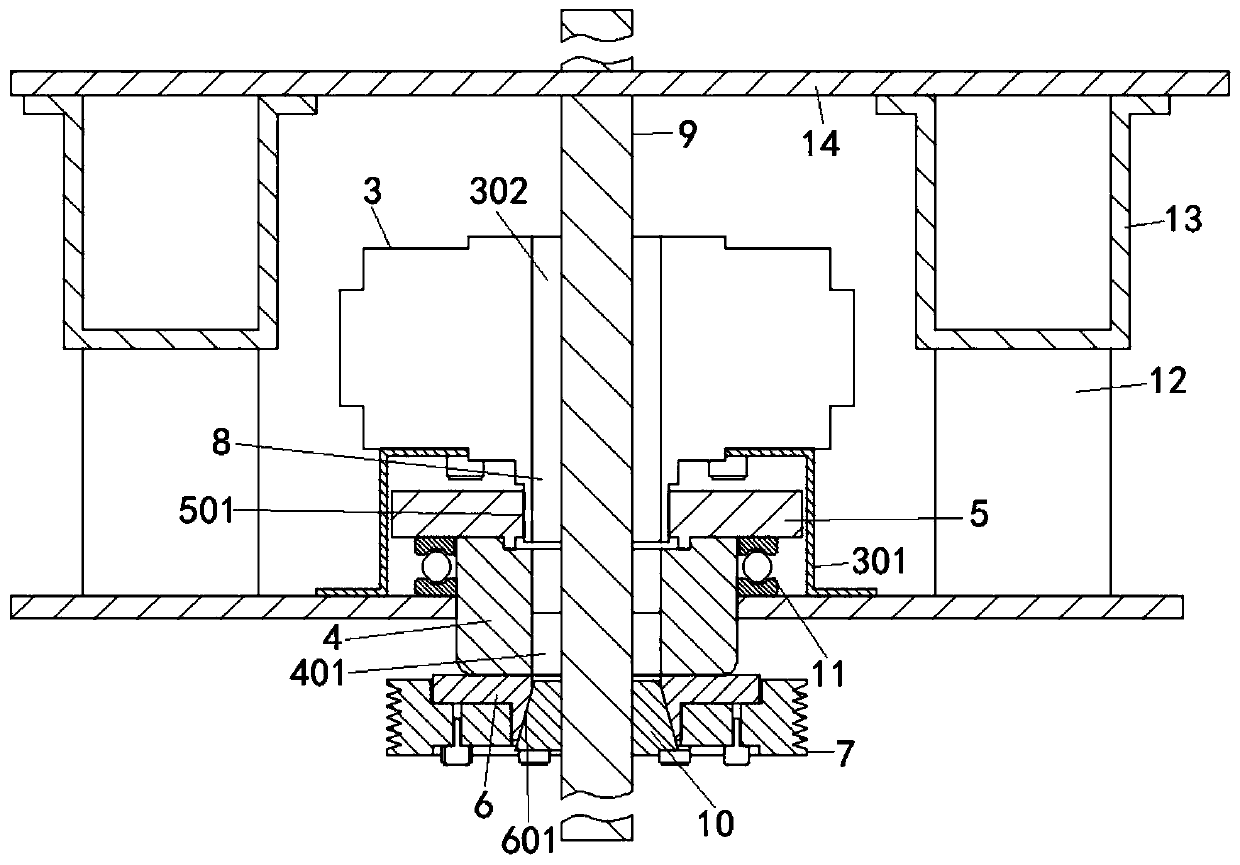

An electro-hydraulic brake mechanism

ActiveCN110821993BGood for brake coolingGuaranteed braking effectNoise/vibration controlBrake actuating mechanismsHydraulic cylinderHydraulic pump

The invention provides an electrical hydraulic brake mechanism. The electrical hydraulic brake mechanism comprises a piston rod, a fixed cover, a piston disc, a hydraulic pump, a centrifugal pump, a brake motor, a connecting shaft, an oil pressure tube head, a line bank, a fixed line bank, a limiting switch, a blocking base structure capable of ventilating, radiating, braking and buffering, a self-return type pressure relief pressure rod structure, a damping type fixed mounting frame structure and an intelligently-controlled dustproof operator structure. According to the electrical hydraulic brake mechanism provided by the invention, a ventilating fan, a braking blocking base, a jointing base, a heat-conduction blocking plate, a movable shaft and a buffer spring are arranged, so that braking and radiating are facilitated, and brake effect is guaranteed; the ventilating fan can radiate a brake assembly to be braked inside the braking blocking base; the heat-conduction blocking plate canperform radiating work; and through buffer action of the buffer spring, the heat-conduction blocking plate can movably operate inside the jointing base through the movable shaft, so that brake stability is guaranteed.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

A new energy vehicle regenerative braking force distribution method and new energy vehicle

ActiveCN112248819BEfficient recyclingGuaranteed braking effectElectrodynamic brake systemsRegenerative brakePower efficient

The invention discloses a new energy vehicle regenerative braking force distribution method and the new energy vehicle, and relates to the technical field of new energy vehicle braking. The method includes: determining the first braking strength limit according to the current braking capability of the motor, and determining the second braking strength limit according to the braking performance and braking stability; according to the braking strength and the first braking strength limit and the second The size relationship of the braking strength limit determines the regenerative braking force distribution strategy, and distributes the total braking force to the rear wheels as much as possible; divides the distributed total rear wheel braking force into the rear wheel friction braking force and the motor braking force. When the braking demand can be met, the total braking force of the rear wheel is distributed to the motor as much as possible, and when the motor cannot meet the braking demand, the frictional braking force of the rear wheel is used to compensate. Through this method, the total braking force can be distributed to the rear wheel braking force according to the maximum braking force that the motor can provide, so that the braking capacity of the motor can be fully utilized, and efficient braking energy recovery can be realized.

Owner:FAW JIEFANG AUTOMOTIVE CO

An electric vehicle electro-hydraulic composite braking system and its optimization method

InactiveCN106043256BImprove braking efficiencyEasy to analyzeBraking action transmissionElectrodynamic brake systemsWheel speed sensorHigh energy

The invention discloses an electric-hydraulic composite braking system for an electric automobile and an optimization method of the electric-hydraulic composite braking system. The electric-hydraulic composite braking system for the electric automobile comprises a motor regeneration braking force module, a hydraulic braking force module and a composite braking force control module. The motor regeneration braking force module comprises two hub motors, a brake pedal position sensor, four wheel speed sensors, an automobile speed sensor, a super-capacitor, a two-quadrant DC-DC converter and a first ECU. The hydraulic braking force module comprises an oil pump motor, a hydraulic oil pump and a second ECU. In the traveling process of the automobile, through detection of the automobile speed and the wheel speed of automobile traveling and brake pedal position signals, the composite braking force control module controls the distribution ratio between the motor regeneration braking force module and the hydraulic braking force module. Meanwhile, through multi-objective optimization conducted on the electric-hydraulic composite braking system, the braking pedal feeling and motor recovered energy serve as objects, and under the ECE laws and regulations, the relatively high energy recovery rate and the proper brake pedal feeling are obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

New energy automobile regenerative braking force distribution method and new energy automobile

ActiveCN112248819AEfficient recyclingGuaranteed braking effectElectrodynamic brake systemsRegenerative brakePower efficient

The invention discloses a new energy automobile regenerative braking force distribution method and a new energy automobile, and relates to the technical field of new energy automobile braking. The method comprises the following steps: a first braking strength limit is determined according to the current braking capacity of a motor, and a second braking strength limit is determined according to braking efficiency and braking stability; a regenerative braking force distribution strategy is determined according to the magnitude relation between the braking strength and the first braking strengthlimit and the second braking strength limit, and the total braking force is distributed to rear wheels as much as possible; and the rear wheel total braking force obtained through distribution is divided into the rear wheel friction braking force and the motor braking force, when the motor can meet the braking requirement, the rear wheel total braking force is distributed to the motor as much as possible, and when the motor cannot meet the braking requirement, the rear wheel friction braking force is used for compensation. According to the method, the total braking force can be distributed tothe braking force of the rear wheels according to the maximum braking force provided by the motor, so that the braking capacity of the motor is brought into full play, and efficient braking energy recovery is realized.

Owner:FAW JIEFANG AUTOMOTIVE CO

Braking system applied to college student equation and working method thereof

ActiveCN114179761AFlexible controlShorten the timeFoot actuated initiationsBrake safety systemsPistonElectric machinery

The invention discloses a braking system applied to a college student equation and a working method of the braking system. The braking system comprises an adjusting base and a braking module. The adjusting base is mounted on the frame; the brake module and the acceleration module are installed on the adjusting base side by side. The brake module comprises a brake pedal, a brake adjusting motor, a transmission flexible shaft, a threaded rod, a front brake oil cylinder U-shaped fork, a brake pedal, a rear brake oil cylinder U-shaped fork and a brake oil cylinder. The middle of the threaded rod is rotationally connected to the bottom end of the brake pedal. Nuts are screwed to the two ends of the threaded rod. And the outer sides of the two nuts, the front brake oil cylinder U-shaped fork and the rear brake oil cylinder U-shaped fork respectively form a revolute pair. And the front brake oil cylinder U-shaped fork and the rear brake oil cylinder U-shaped fork are respectively connected with pistons of the two brake oil cylinders. Through cooperation of the motor and the flexible shaft, the threaded rod serving as a lever is driven to rotate, the ratio of input oil pressure of front and rear wheel brakes is adjusted through rotation of the threaded rod, and flexible control over braking force of front and rear wheels is achieved.

Owner:HANGZHOU DIANZI UNIV

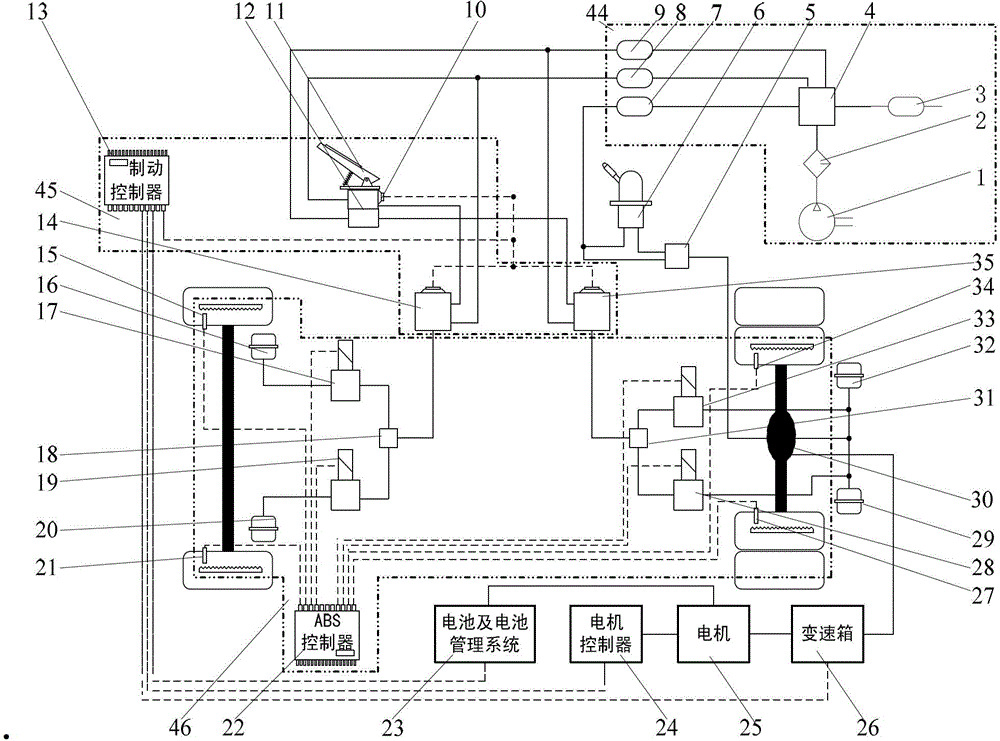

Energy-feedback active control type air braking system

InactiveCN102745183BReduced Braking HazardsIncrease mileageFluid braking transmissionEnergy recoveryElectric control

The invention provides an energy-feedback active control type air braking system, relates to an air braking system of electric automobile energy feedback and belonging to the field of electric automobiles. The energy-feedback active control type air braking system comprises a high-air-pressure generation module, an active air pressure control module and an ABS (Anti-skid Brake System) module, wherein the high-air-pressure generation module is used for generating high-pressure air for the whole automobile under certain pressure; and the active air pressure control module comprises a pedal displacement sensor, a brake pedal, a brake valve, a brake controller, a front-axle double-control proportional relay valve and a rear-axle double-control proportional relay valve. The energy-feedback active control type air braking system is capable of realizing ideal distribution of a braking force and maximization of the rate of energy recovery. The energy-feedback active control type air braking system employs the double-control proportional relay valves to realize active real-time accurate distribution of the braking forces of a front axle and a rear axle, the braking motor of a driving shaft motor and the mechanical braking force; and simultaneously, the energy-feedback active control type air braking system is capable of guaranteeing braking security by starting the conventional braking manner when the electric control part of the double-control proportional relay valves becomes invalid. Furthermore, the energy-feedback active control type air braking system provided by the invention is applied to electric vehicles having the air braking system.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Vacuum cleaner tension wheel frame dislocation balance structure

The invention discloses a dislocation balance structure of a tension wheel frame of a vacuum cleaner, which is installed at a coil reel, and comprises: a tension wheel frame bracket, which is rotatably connected to a rotating shaft of the coil coil, and a shaft body is arranged transversely on the tension wheel frame bracket , the two ends of which form the first connection part; the tensioner frame, which includes the first frame unit and the second frame unit arranged in a dislocation, and the two outer sides of the joint are provided with the second connection corresponding to the first connection part part, the tension wheel frame is connected to the tension wheel frame support through the first connection part and the second connection part, the free end of the first frame body unit is rotatably connected with the tension wheel, and the free end of the second frame body unit is used as the force application point . Compared with the prior art, the present invention does not need to guarantee the force application point at the center position of the tension wheel frame, but only needs to apply the force on the free end of the second frame unit, so it can effectively overcome the problems in the prior art. The phenomenon of tension wheel deviation caused by the deviation of the force point from the center.

Owner:SUZHOU CHUNJU ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com