Optimization method of braking force distribution in commercial vehicle integrated braking system under different working conditions

A technology of braking force distribution and braking conditions, applied in electric braking systems, braking transmissions, brakes, etc., can solve different problems, achieve the effects of preventing thermal recession, fast braking response, and improving economic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

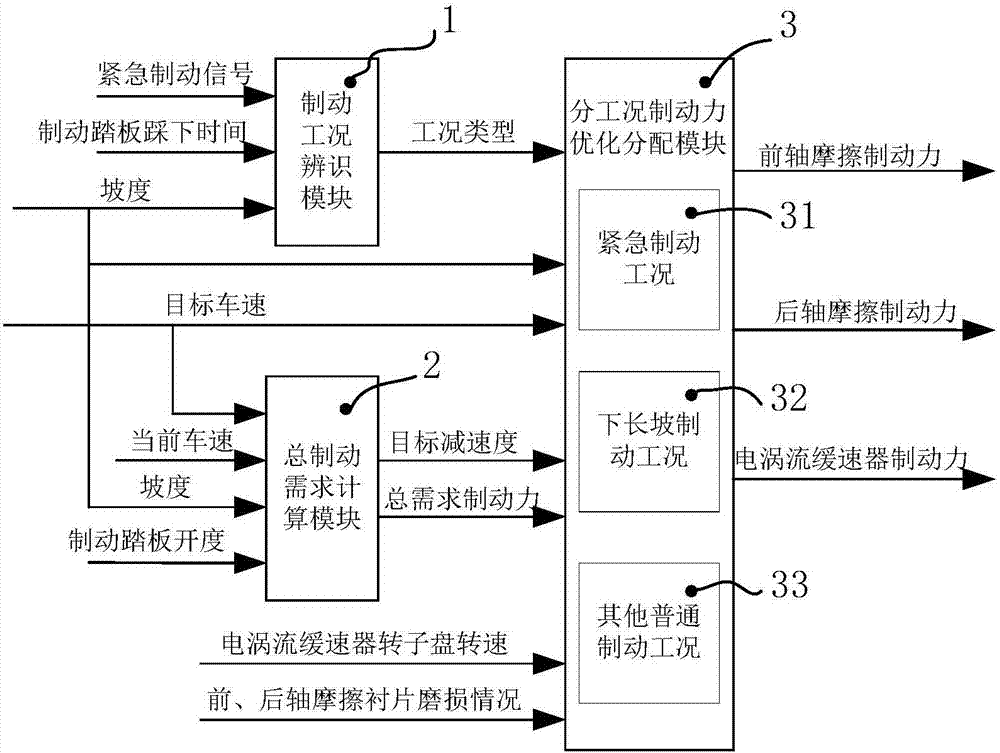

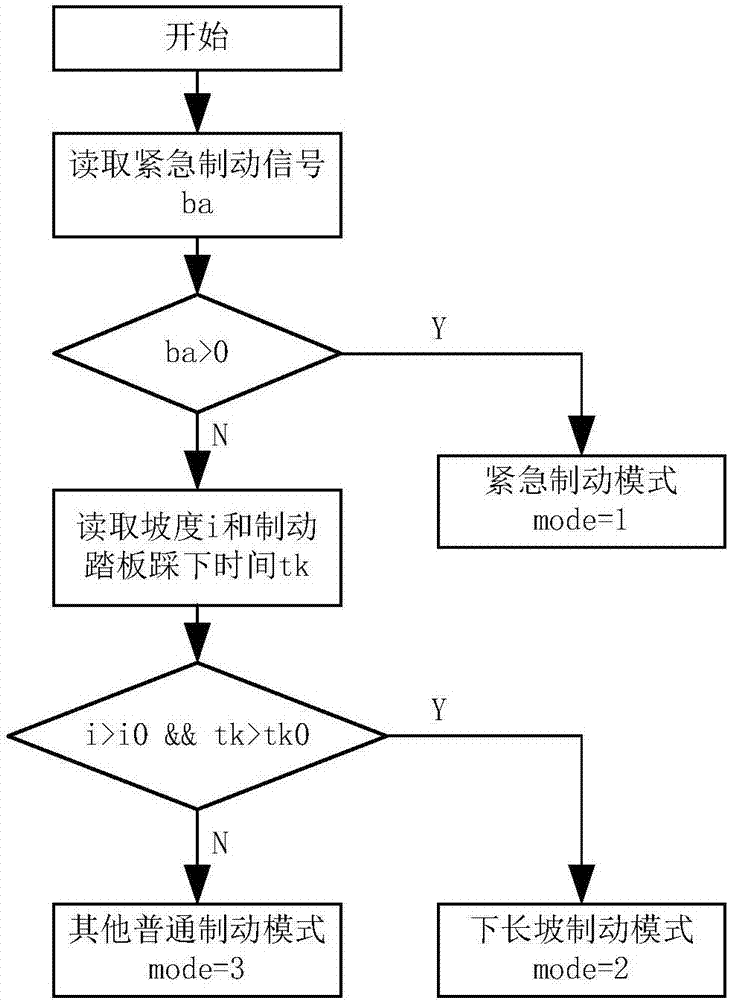

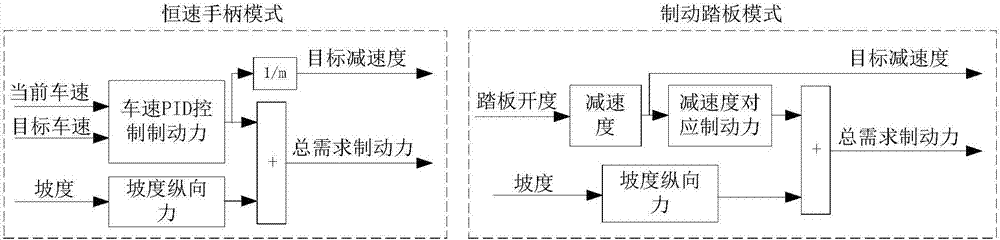

[0024] The braking force distribution optimization method for commercial vehicle integrated braking system proposed by the present invention is suitable for commercial vehicles equipped with pneumatic electronic control braking system and eddy current retarder. There are three types of braking, downhill braking and other ordinary braking. The braking conditions are identified online through the brake pedal signal, road gradient and emergency braking signals. According to the identification results, different braking conditions are used. Different control objectives are used to dynamically allocate and optimize the braking force of the three brake actuators of the pneumatic electric control braking system, the front axle friction braking force, the rear axle friction braking force and the eddy current retarder braking force. Emergency braking conditions aim at braking st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com