An electric vehicle electro-hydraulic composite braking system and its optimization method

An electric vehicle, electro-hydraulic composite technology, applied in electric braking systems, electric vehicles, brakes, etc., can solve problems such as limiting braking energy recovery effect, driver braking stability, and driver inconsistent braking feeling. , to increase the brake pedal feel, improve the overall optimization ability, and improve the braking performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

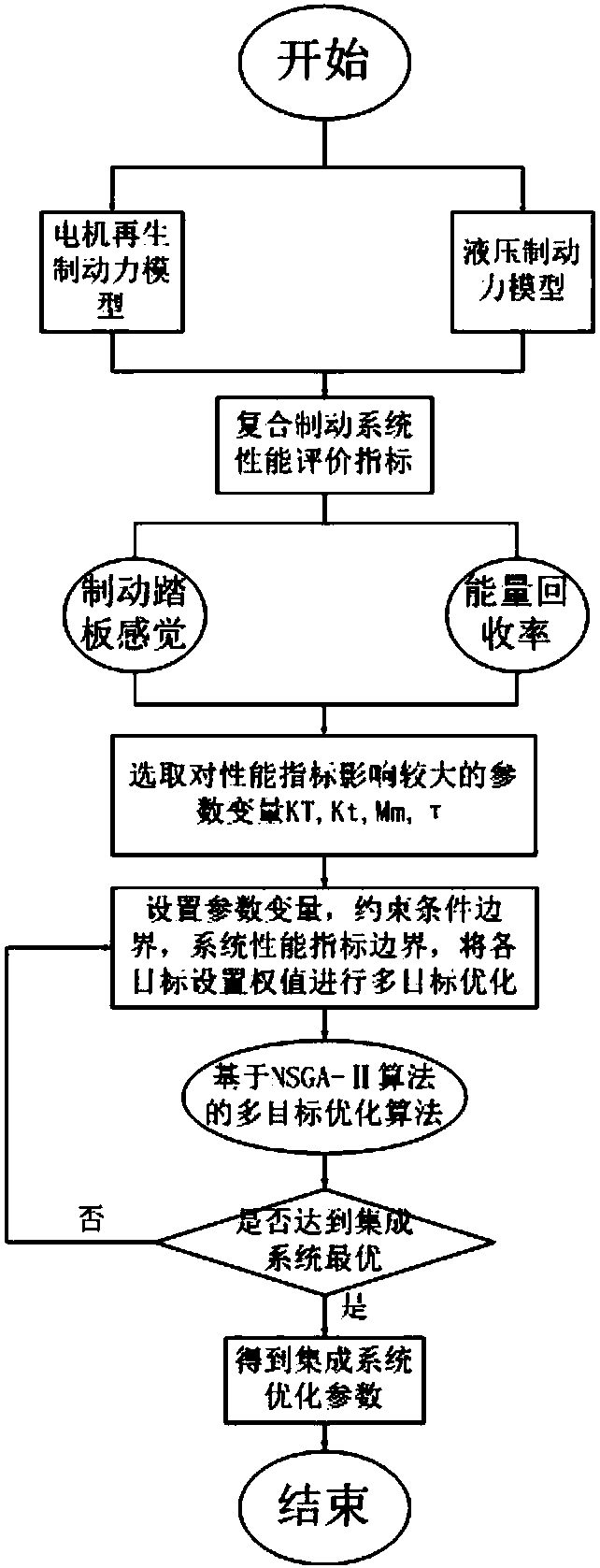

[0055] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

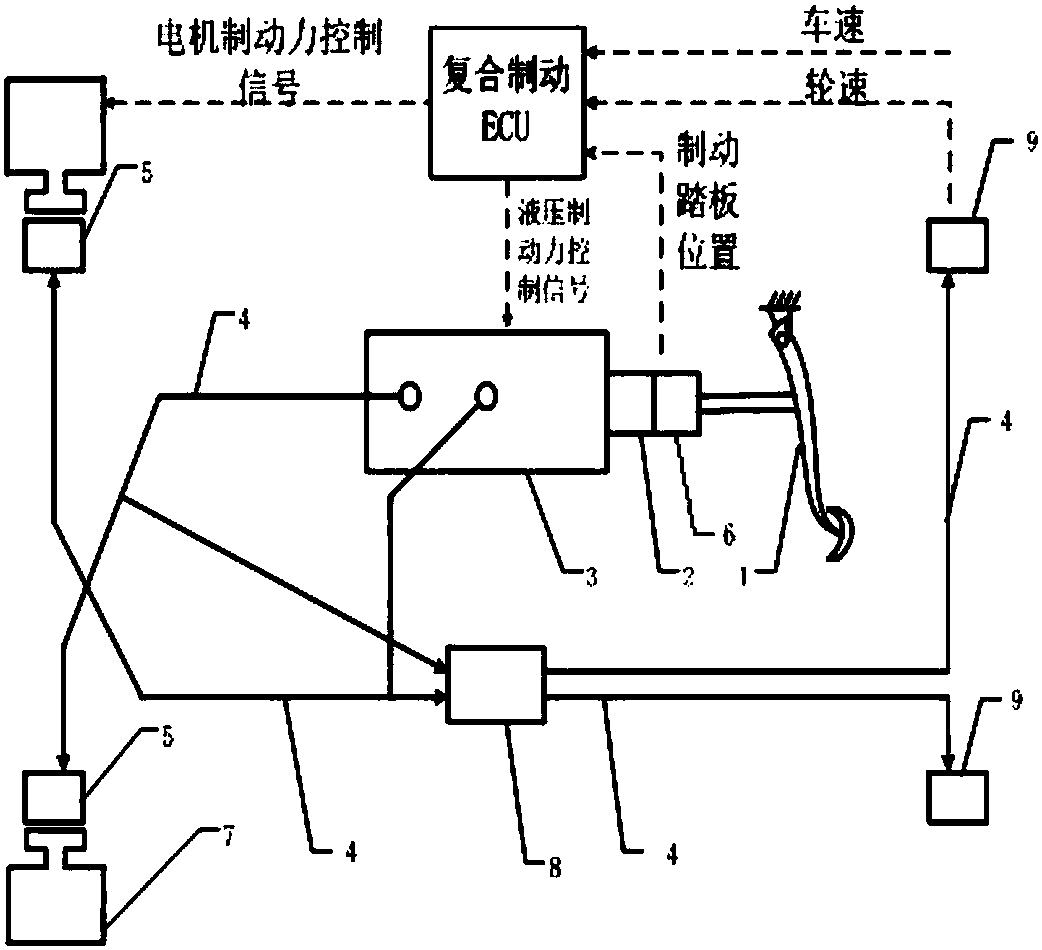

[0056] Such as figure 1 As shown, the present invention discloses an electro-hydraulic composite braking system for an electric vehicle, which includes a motor regenerative braking force module, a hydraulic braking force module and a composite braking force control module;

[0057] The motor regenerative braking force module includes two hub motors, a brake pedal position sensor, four wheel speed sensors, a vehicle speed sensor, a super capacitor, a two-quadrant DC-DC converter and a first ECU;

[0058] The two in-wheel motors are correspondingly arranged in the two front wheels of the electric vehicle for driving and braking the two front wheels;

[0059] The brake pedal position sensor is arranged at the brake pedal, and is used to obtain the stroke of the brake pedal when the brake pedal is stepped on;

[0060] The four wheel speed sensors are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com