An electro-hydraulic brake mechanism

A hydraulic brake and brake motor technology, applied in the direction of brake actuators, brake types, brake components, etc., can solve the problems of poor braking stability, inconvenient installation and fixing, and no limit function, etc. Dynamic stability, guaranteed braking ability, guaranteed braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

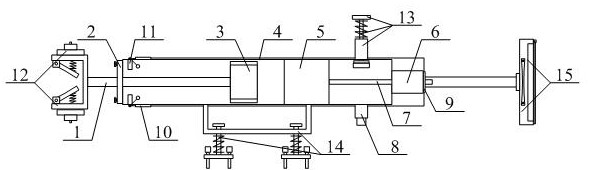

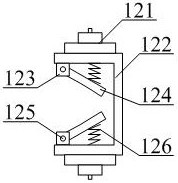

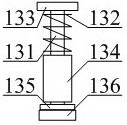

[0048] Below in conjunction with accompanying drawing, the present invention is described in detail, as shown in accompanying drawing 1 and accompanying drawing 2, a kind of electro-hydraulic braking mechanism comprises piston rod 1, fixed cover 2, piston disc 3, hydraulic cylinder 4, centrifugal pump 5, Brake motor 6, connecting shaft 7, oil pipe head 8, wiring bar 9, fixed line bar 10, limit switch 11, ventilated heat dissipation brake buffer deck structure 12, self-resetting pressure relief bar structure 13 , a shock-absorbing fixed mounting frame structure 14 and an intelligently controllable dust-proof operating machine structure 15, the lateral gap of the piston rod 1 runs through the inner middle position of the fixed cover 2; the piston disc 3 bolts are connected to the piston rod 1 The middle position of the left end; the fixed cover 2 bolts are connected to the left end of the hydraulic cylinder 4; the piston disc 3 is movably arranged inside the hydraulic cylinder 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com