Split type structure train wheel

A body structure, train technology, applied to the direction of wheels, wheels characterized by rail running parts, vehicle parts, etc., can solve the problems of large weight, large stress and energy, heavy quality, etc., and achieve the effect of easy repair and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

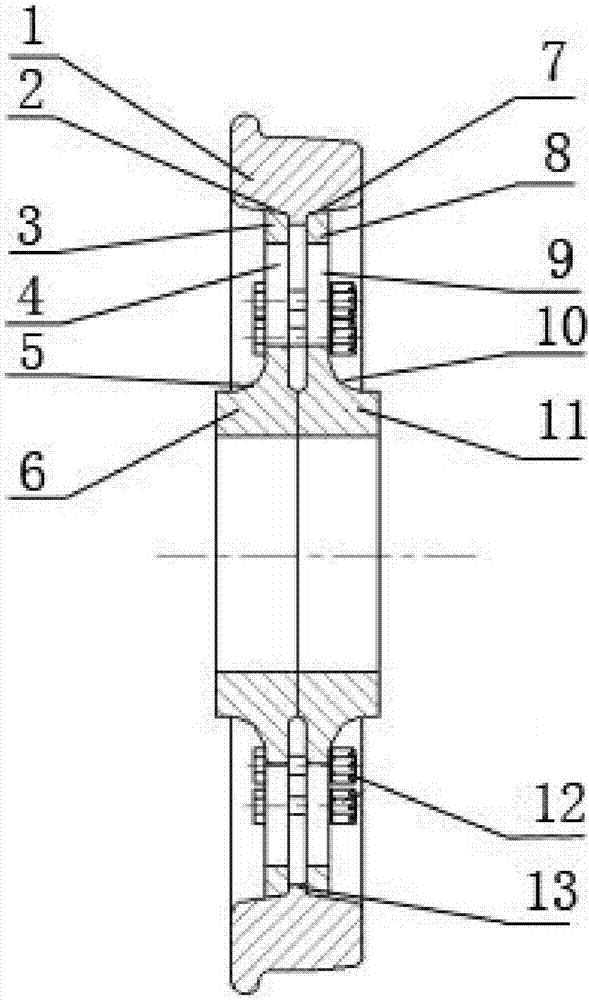

[0019] like figure 1 As shown, the split-type train wheel includes: rim 1, inner inclined surface 2, inner spoke 3, inner lightening hole 4, inner curved surface 5, inner hub 6, outer inclined surface 7, outer spoke 8, outer lightening hole 9 , Outer curved surface 10, outer hub 11, bolt 12. The rim 1 is integrally formed by forging. The inner ring of the rim 1 has a boss 13. The inner slope 2 and the outer slope 7 are symmetrical on both sides of the boss 13, and the inclination angle relative to the horizontal plane is 8°; the inner spoke 3 and the outer spoke 8 The outer edge is processed with an inclination angle of 8° relative to the horizontal plane, and fits with the rim 1; the inner spoke 3 is provided with an inner weight-reducing hole 4, and the outer spoke 8 is provided with an outer weight-reducing hole 9; the inner spoke 3 and the inner hub 6 The junctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com