Method for controlling anti-lock system of four-hub-motor drive electric car free of hydraulic braking

An anti-lock braking system and in-wheel motor technology, applied in the direction of brakes, etc., can solve the problems of reducing vehicle flexibility, increasing body quality, impact and wear, etc., to ensure braking stability, vehicle braking stability, and reliability and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical solution, purpose and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings.

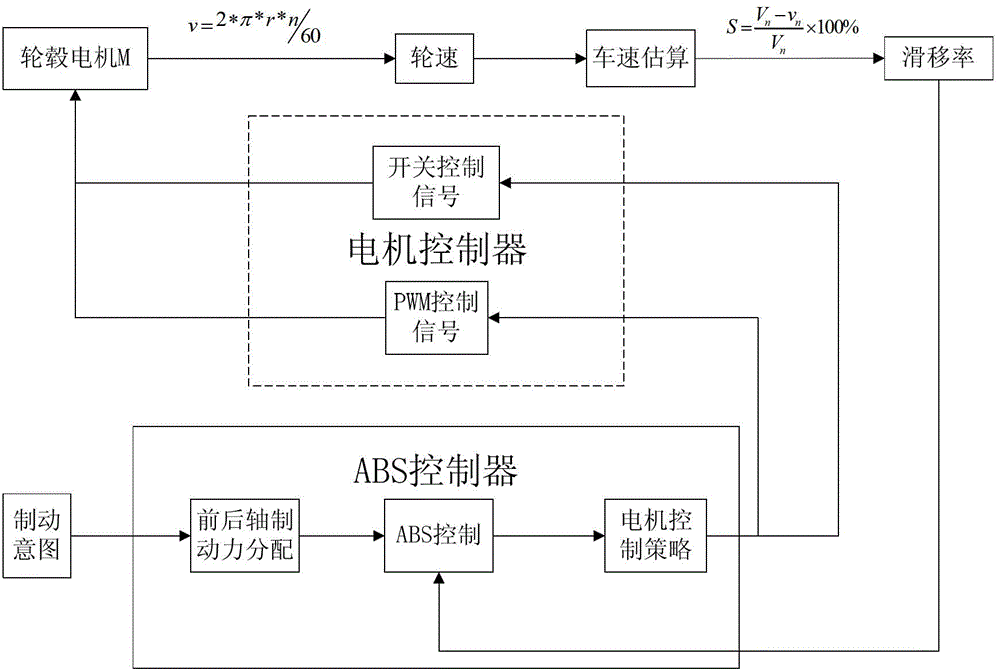

[0029] The present invention is a control method for the anti-lock braking system (ABS) of an electric vehicle driven by a four-wheel hub motor without hydraulic brakes. Its structure is as attached figure 1 shown. After determining the braking intention of the vehicle, the braking force of the front and rear axles is distributed, combined with the current wheel speed and slip ratio, the motor control is realized through the ABS controller and the motor controller.

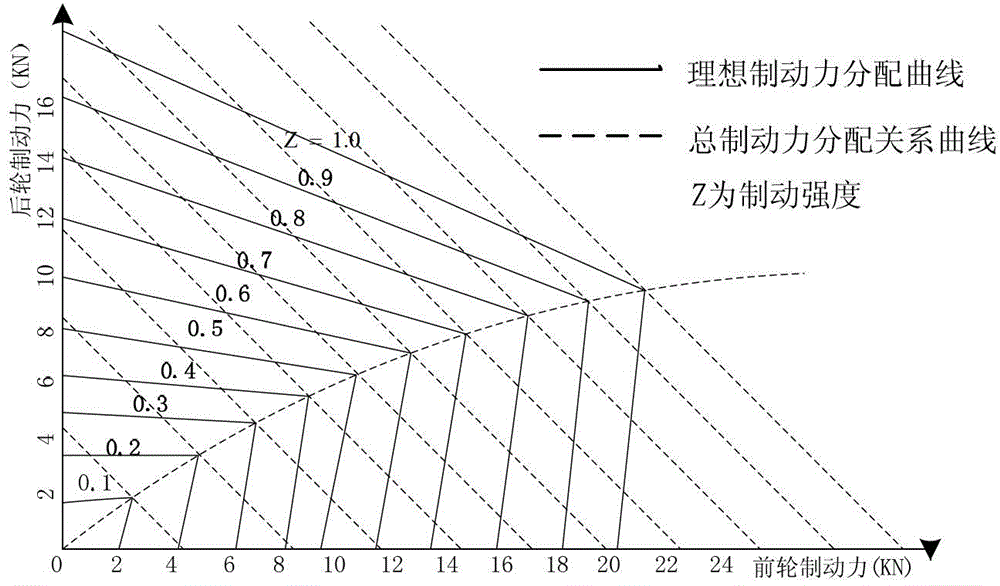

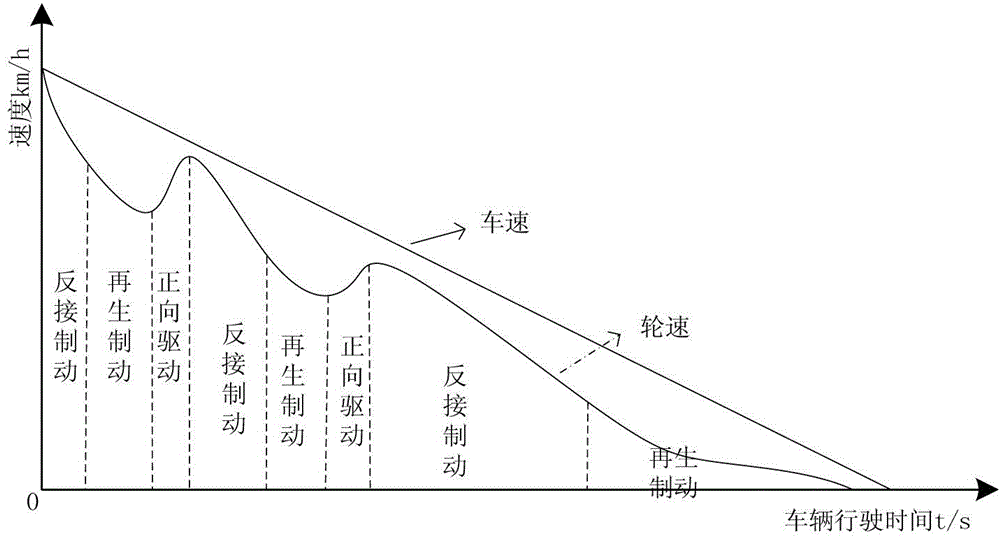

[0030] to combine figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , the control method mainly includes the following aspects: braking force distribution, braking intention judgment, slip rate calculation and control logic.

[0031] (1) Braking force distribution system. Braking force distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com