Integrated electric servo brake system for vehicle

A technology that integrates electric and braking systems. It is applied to brakes, vehicle components, and brake transmissions. It can solve problems such as frequent use and poor reliability, and achieve the effects of increasing speed, maintaining foot feel, and good foot feel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

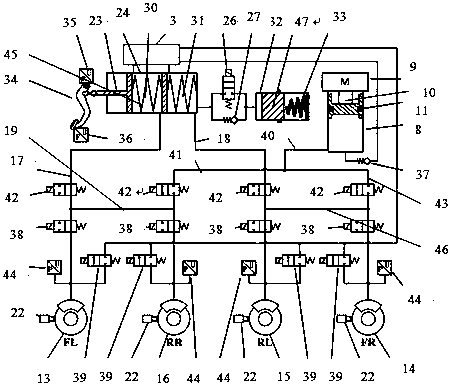

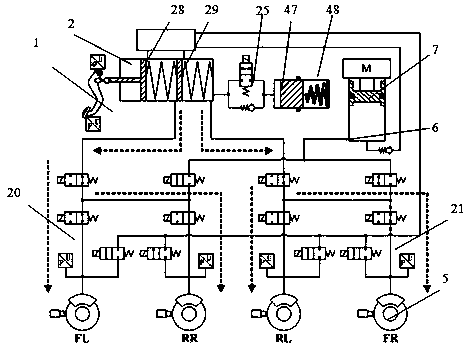

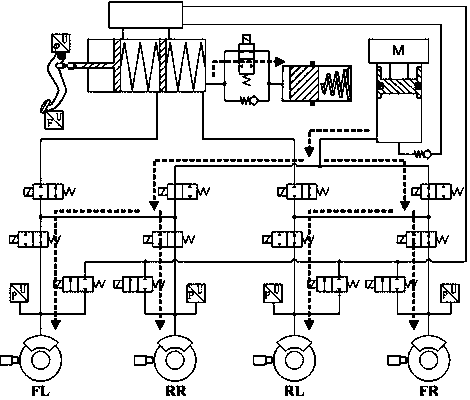

[0052] Embodiment 1: The present invention provides a vehicle integrated electric servo braking system, including: a brake operating mechanism 1; a brake master cylinder assembly 2, including a liquid storage tank 3; Master cylinder assembly; wheel brake assembly 4, including brake wheel cylinder 5; the brake master cylinder assembly communicates with the brake wheel cylinder; hydraulic circuit 6, including a booster module 7; wherein, the booster module includes A booster cylinder 8, a motor 9 and a ball screw 10 rigidly connected to the motor, the booster cylinder is provided with a hydraulic piston 11; the hydraulic piston 11 is installed inside the cylinder of the ball screw; The motor drives the ball screw to move, so that the ball screw drives the hydraulic piston to move; one end of the booster module is connected to the liquid storage tank, and the other end is connected to the brake wheel cylinder.

Embodiment 2

[0053] Embodiment 2: as figure 1 , Figure 5 As shown, the present invention provides a vehicle integrated electric servo braking system. The present invention provides a vehicle integrated electric servo braking system, including: a brake operating mechanism; a brake master cylinder assembly and an electronic control unit 12, including Liquid storage tank; the brake control mechanism transmission connection brake master cylinder assembly; wheel brake assembly, including the brake wheel cylinder; the brake master cylinder assembly is connected to the brake wheel cylinder; hydraulic circuit, including the booster module; wherein, the supercharging module includes a supercharging cylinder, a motor and a ball screw rigidly connected to the motor, and a hydraulic piston is arranged in the supercharging cylinder; the said supercharging module is installed inside the cylinder of the ball screw; the said The ball screw is also connected to the hydraulic piston, and the motor drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com