Regenerative braking system and braking method for wheel hub motor-driven automobile

An in-wheel motor and regenerative braking technology, applied in the direction of brake transmission, brakes, vehicle components, etc., can solve the problem of lack of regenerative braking technology in four-wheel drive pure electric vehicles, and achieve the effect of improving braking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

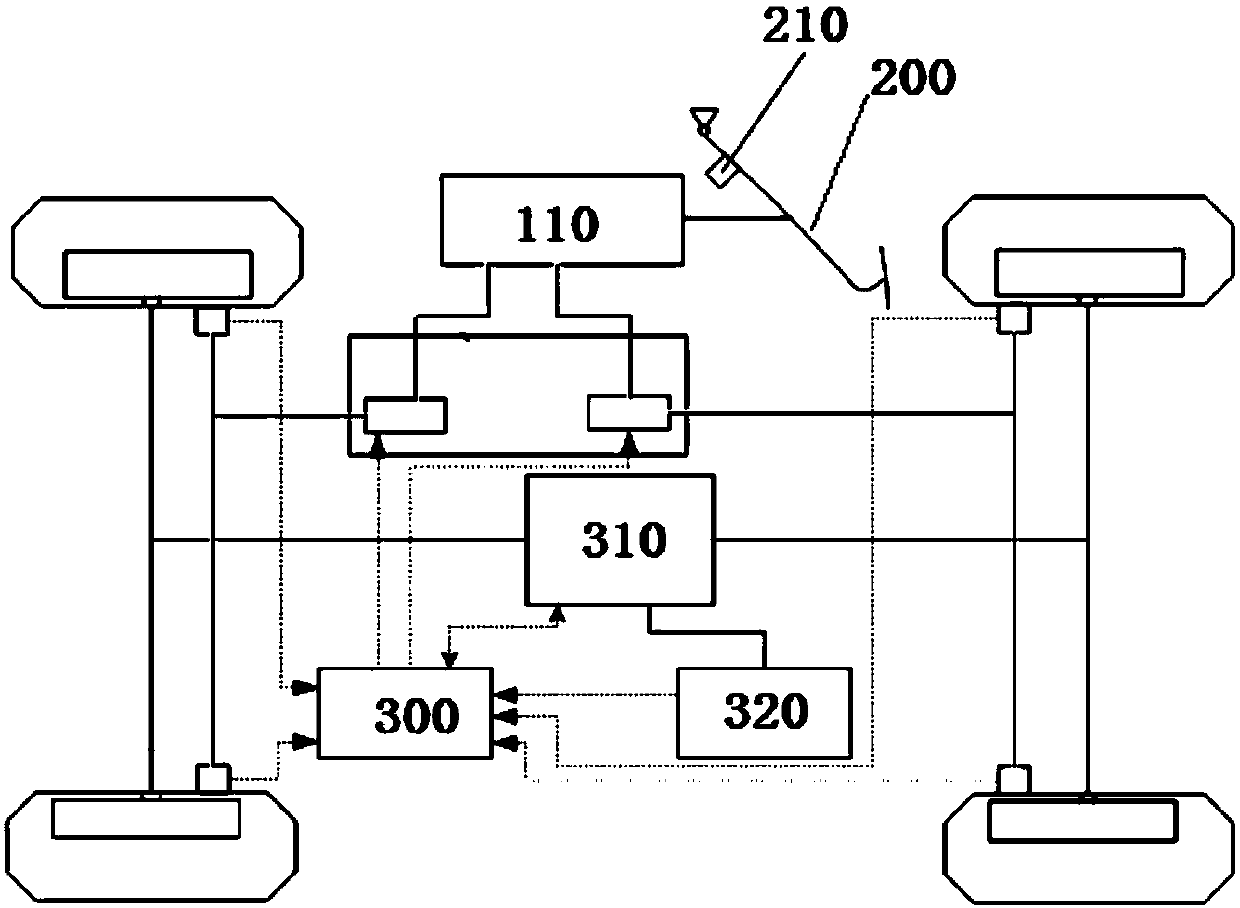

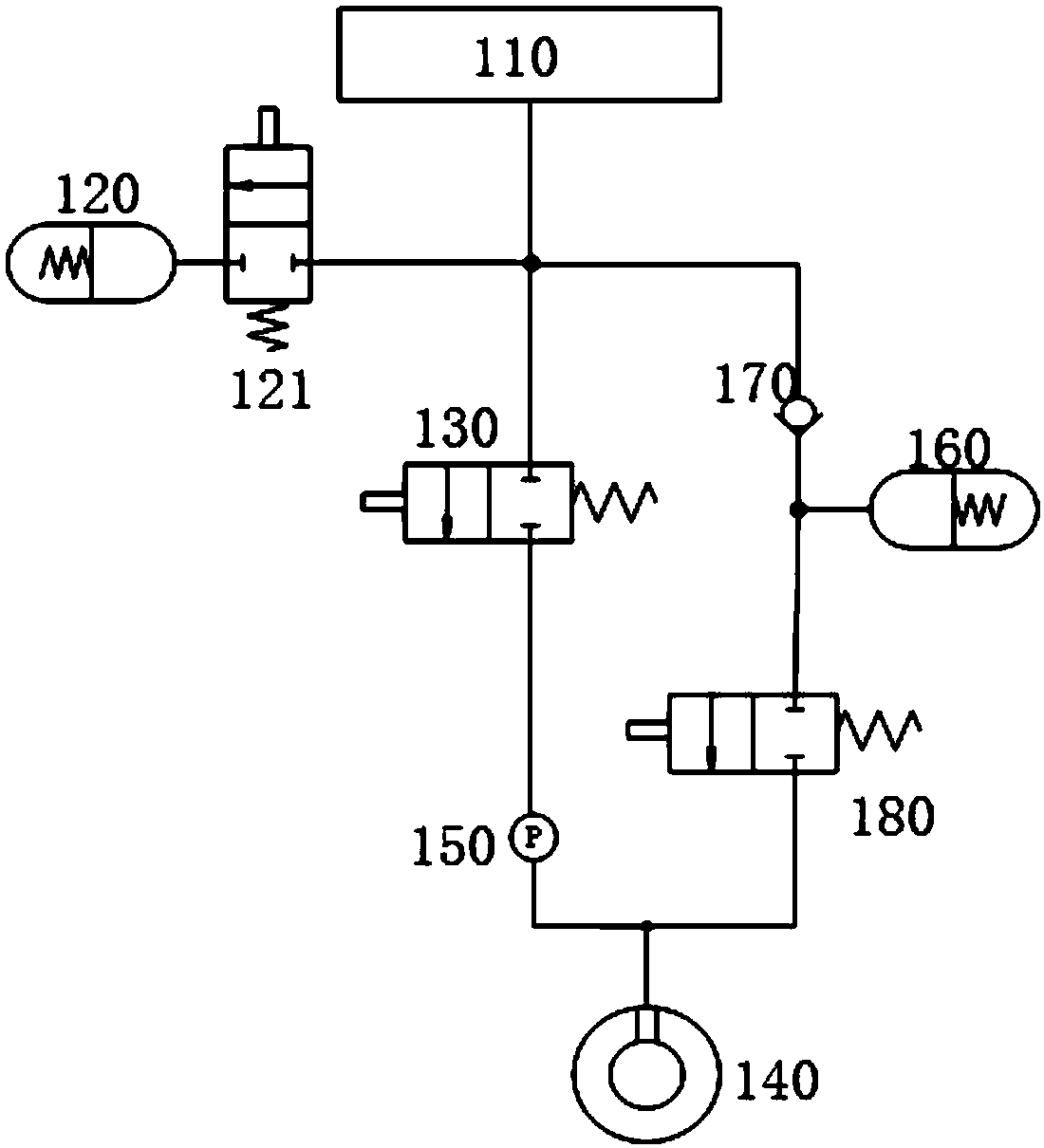

[0051] Such as figure 1 , 2As shown, the present invention provides a regenerative braking system for an in-wheel motor driven vehicle, which includes an in-wheel motor regenerative subsystem and a hydraulic braking subsystem. The hydraulic braking subsystem includes: a brake master cylinder 110; and a first energy storage The device 120 is connected to the brake master cylinder 110 and is provided with an on-off valve 121. Its functions are mainly reflected in two aspects. One is to store the high pressure from the brake master cylinder 110 under pure motor braking conditions. The brake fluid follows the driver's braking operation, and the second is to quickly build up the hydraulic braking force without affecting the hydraulic braking force when the braking capacity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com