Ultra-high-speed and super-cavitation catamaran with hydrofoils

A catamaran and supercavitation technology, which is applied in the direction of hull, hull design, ship construction, etc., can solve the problems of reduced propulsion efficiency, inability to effectively increase the speed of the ship, and low propulsion efficiency, so as to increase the speed of the ship and eliminate the phenomenon of cavitation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

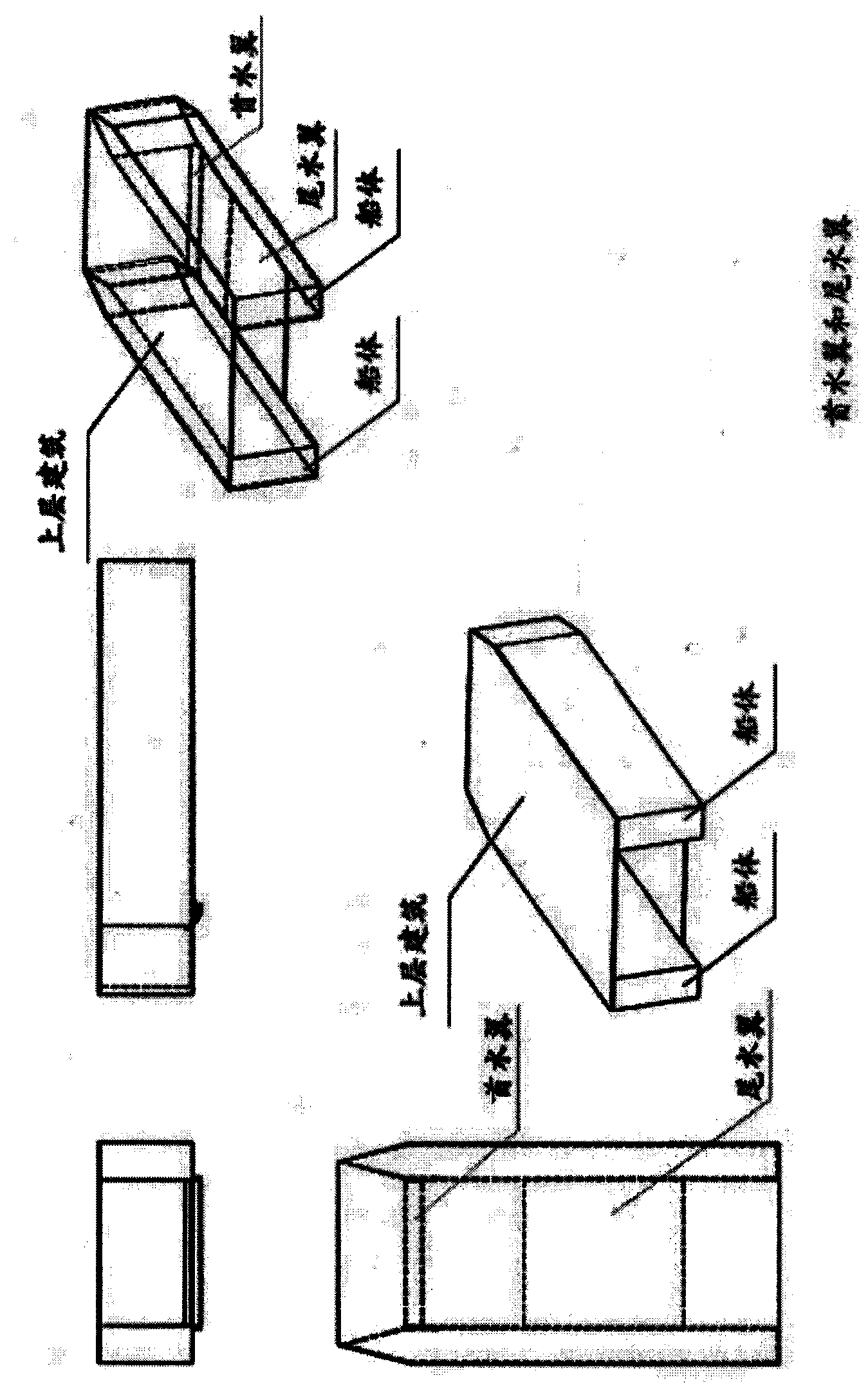

[0023] (1) The bow hydrofoil is an adjustable ascending wing installed in the bow of the ship. During sailing, the lift of the hull is controlled. The stern hydrofoil is the main hydrofoil extending equidistantly from the center of gravity to the bow and aft, and is connected to the bottom plane of the two hulls on the same plane. , Is a fixed main hydrofoil.

[0024] (2) Use a ventilation device to connect the lift surface of the hydrofoil and the front transverse edge of the bottom surface of the hull. When sailing, the hydrofoil and the bottom surface of the ship are separated from the water by a thin air film, and the hydrofoil and the bottom of the ship achieve supercavitation.

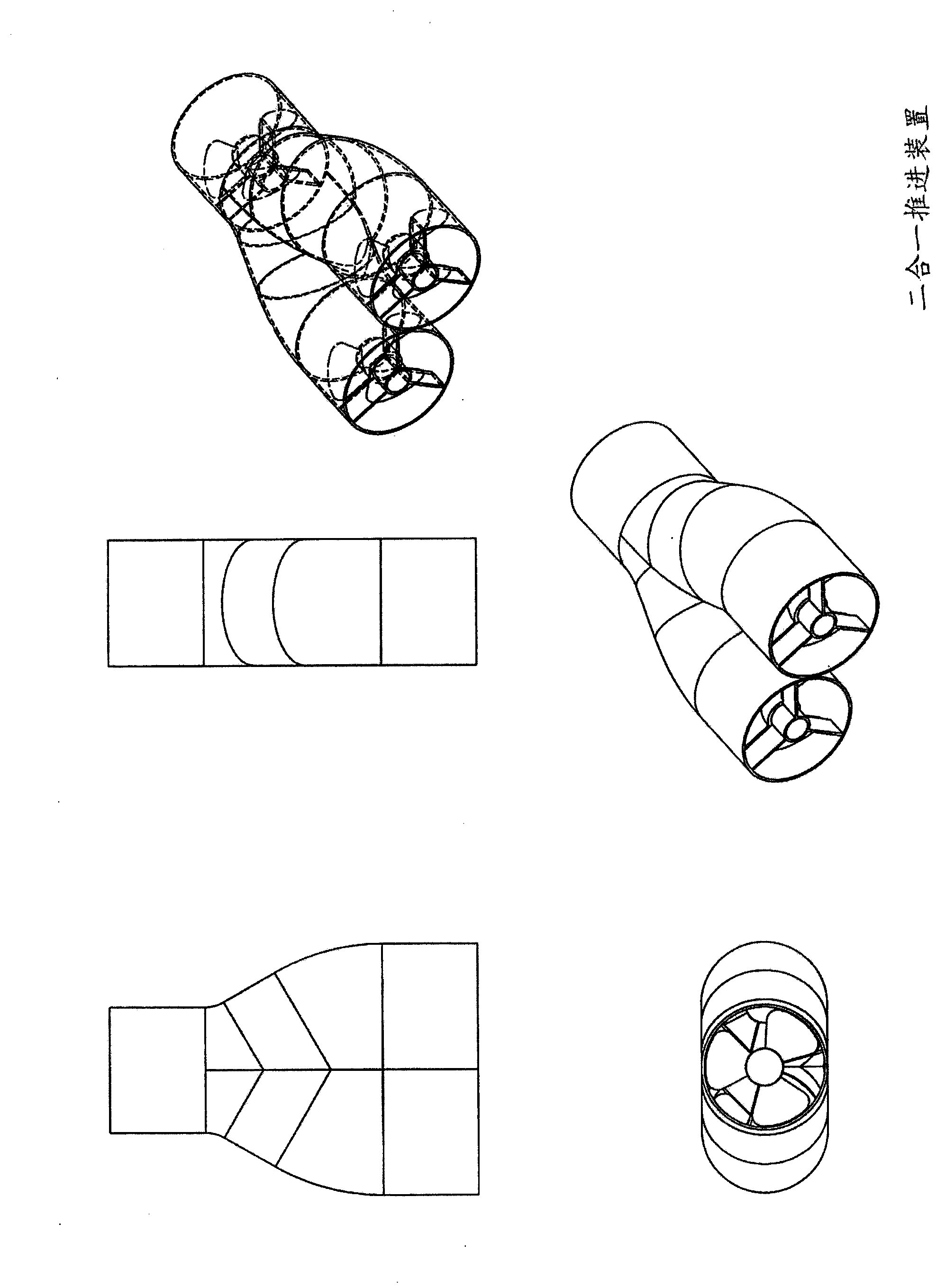

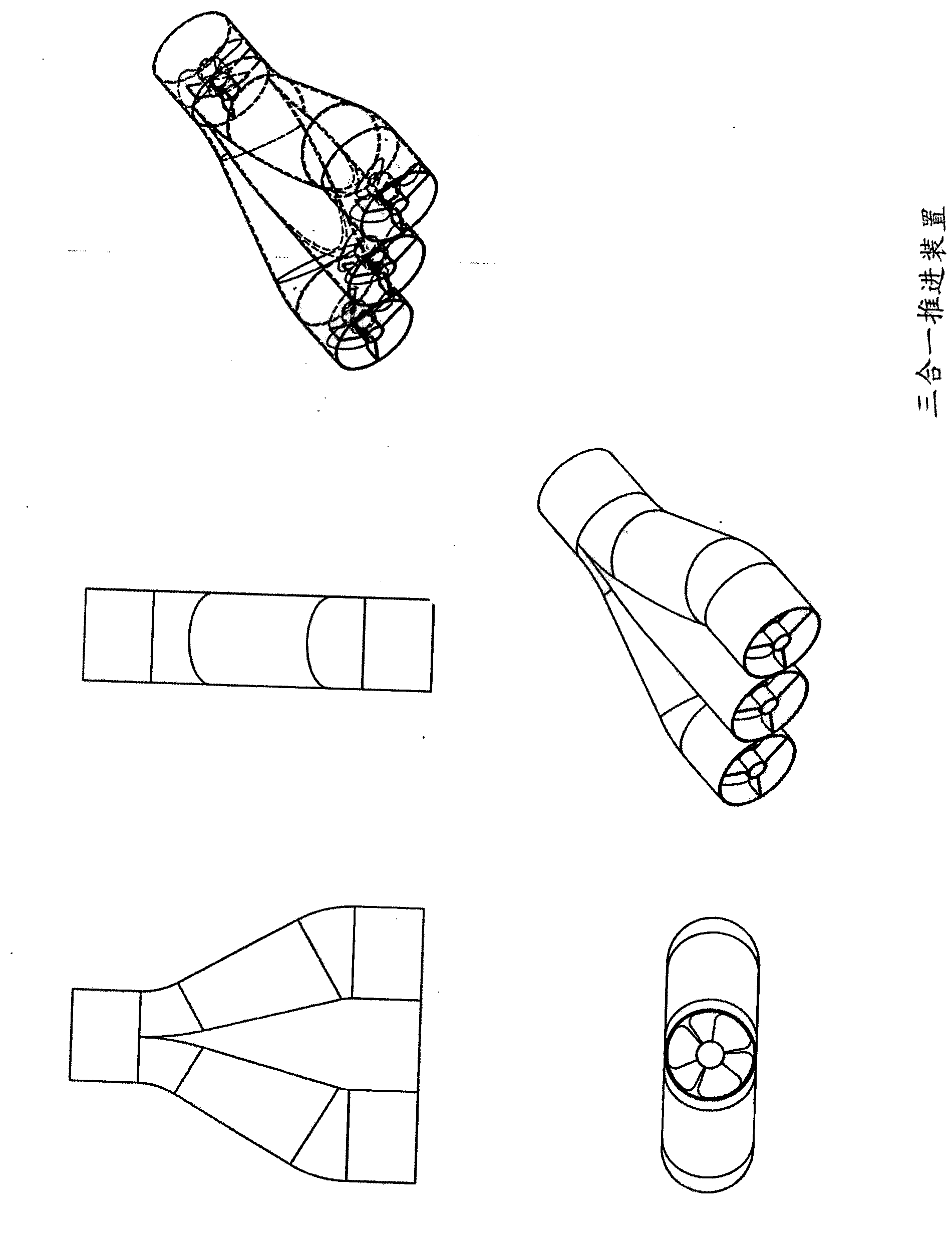

[0025] (3) Combine two water inlet pipes in the middle, and a water outlet at the back is a two-in-one channel combined propeller propulsion device, and three water inlet pipes are combined in the middle, and a water outlet at the back is a three-in-one. One channel combined propeller propulsion devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com