Ultra-high speed aircraft thermal protection and drag reduction method and system

An aircraft, ultra-high-speed technology, applied in the thermal protection device of the aerospace vehicle, the device for the control of the living conditions of the aerospace vehicle, and the influence of the air flow flowing through the surface of the aircraft, etc., can solve the problem of heat protection, accidental failure, and endanger Carry system security and other issues to achieve the effect of improving energy efficiency and limit speed, slowing down or avoiding thermal barrier phenomenon, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In order to make the technical solution of the present invention clearer, the thermal protection and drag reduction system of the ultra-high-speed aircraft of the present invention will be further described in detail in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention and not to limit the present invention.

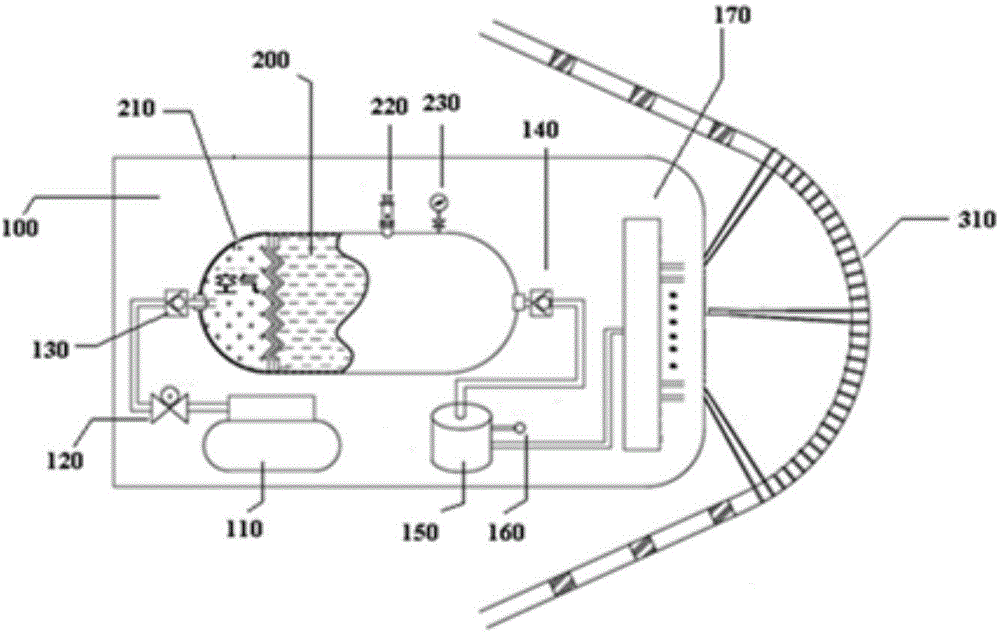

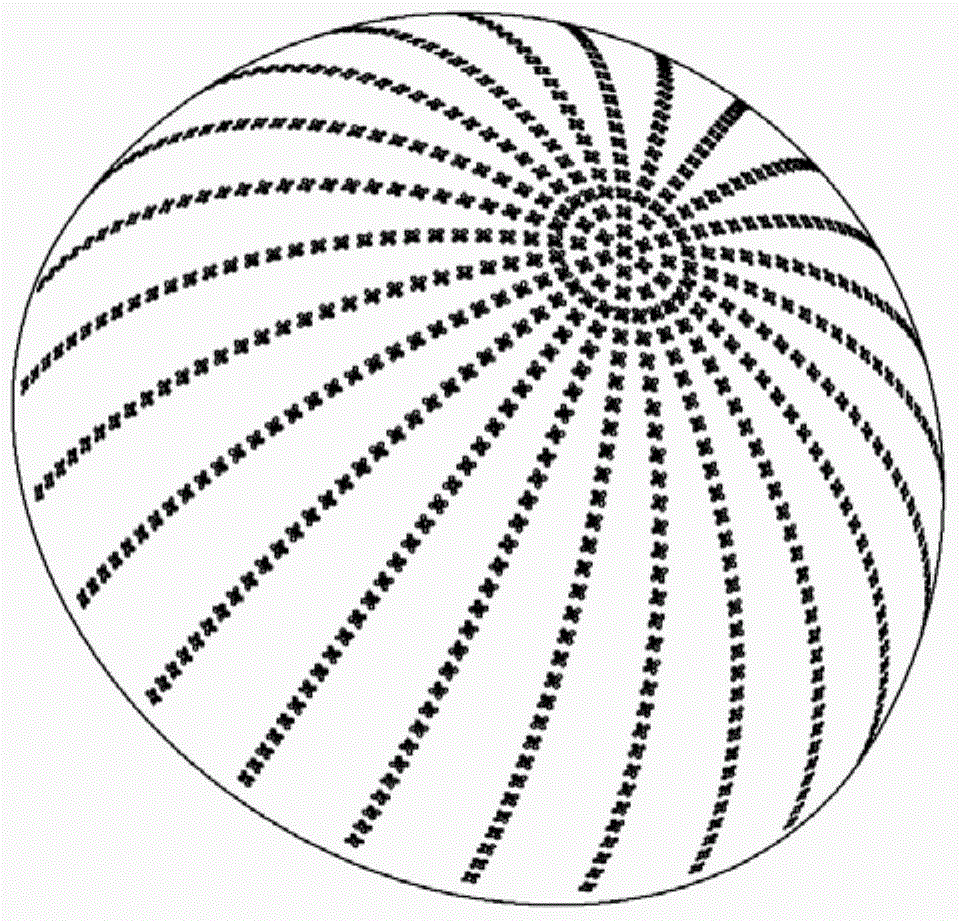

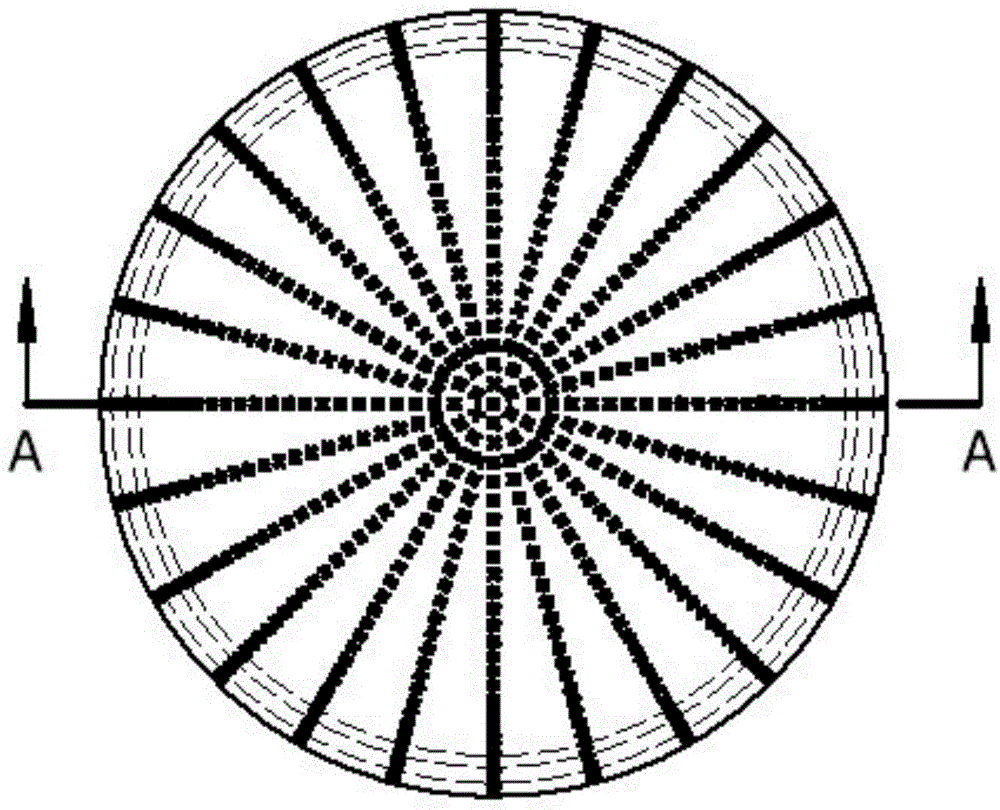

[0047] In this example, if figure 1 As shown, the ultra-high-speed aircraft includes a sealed cavity, and the drag reduction and thermal protection system of the ultra-high-speed aircraft includes a cold source 200 arranged inside the sealed cavity of the ultra-high-speed aircraft, and is used to convert the cold source 200 into a high-pressure gas and eject it The cold source driving device 100. The wall surface 310 of the head portion of the sealed cavity of the ultra-high-speed aircraft is a sandwich structure. figure 2 is a schematic diagram of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com