Method for controlling oil and gas well drilling to reduce drill string viscous resistance

A technology of oil and gas, viscous resistance, applied in drilling equipment and methods, drilling equipment, drilling automatic control system, etc., can solve the problems of decreased drilling efficiency and drilling pressure, and achieve the effect of improving efficiency and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

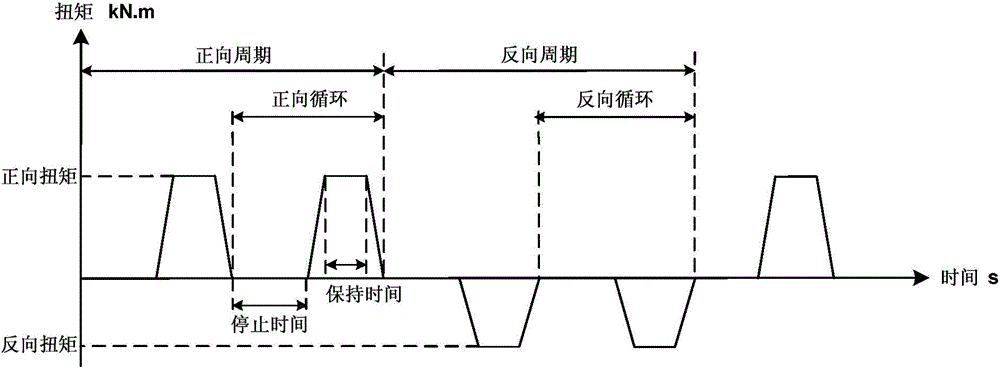

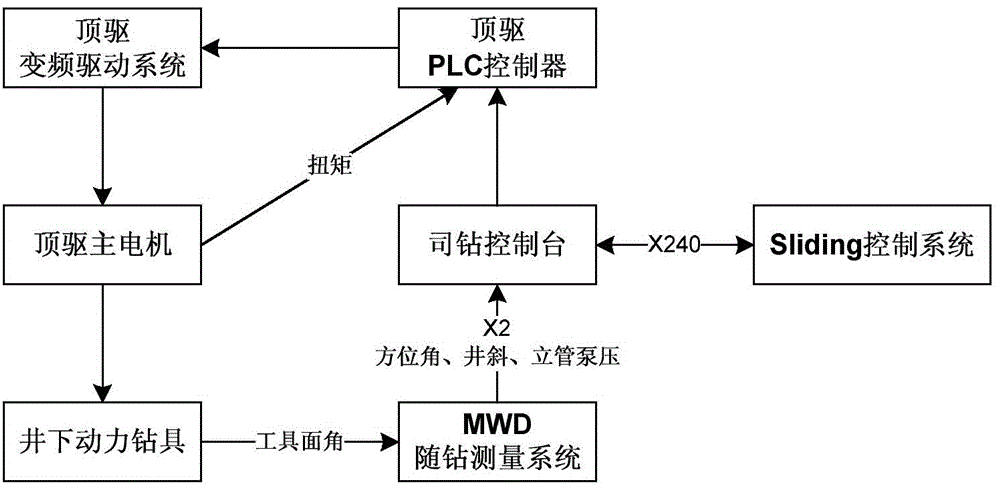

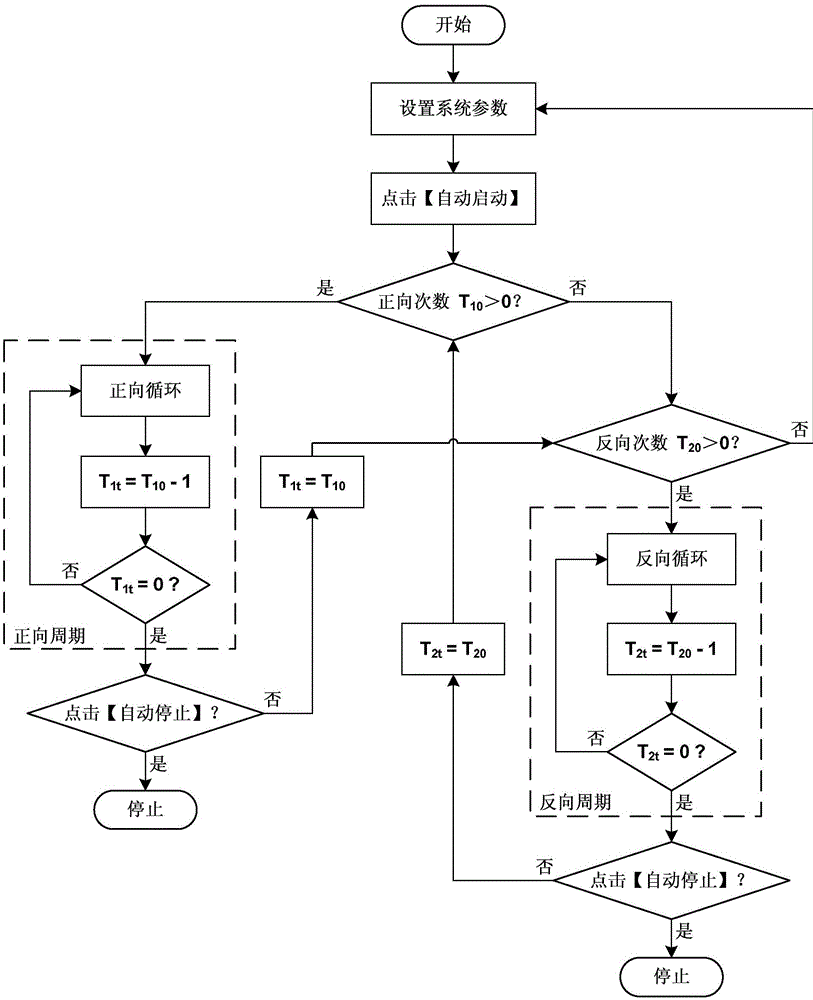

[0033] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, a method of controlling oil and gas drilling to reduce the viscous resistance of the drill string,

[0034] The method and system proposed by the present invention are also applicable to other types of drilling rigs, such as drilling rigs and ocean drilling rigs, which rely on the rotary table and kelly to provide rotational power.

[0035] The top drive body is suspended on the derrick through the hook connected with the travel car, and can move up and down along the vertical guide rail parallel to it. In the rotary drilling mode, the top drive main motor drives the top drive main shaft to rotate, and then drives the drill string connected to it to rotate, and the middle drill string in the wellbore also rotates accordingly. In the sliding drilling mode, the middle drill string has been rotated into place (that is, not rotating) driven by the top drive, while the drill bit is rotated by the downhole power mo...

Embodiment 2

[0090] Embodiment 2: as figure 1 , figure 2 , image 3 As shown, a method of controlling oil and gas drilling to reduce the viscous resistance of the drill string. Aiming at the problems of large friction between the drill string and the well wall, unstable pressure on bit, and low ROP in the traditional directional drilling technology, the drilling tool was studied. Combining the upper torque generated by the connected top drive, rotary table and other power devices, the reaction torque generated by the downhole power drilling tool and the friction resistance torque between the drill string and the well wall, so that the friction torque balances the upper rotation torque and bottom hole reaction torque to achieve The ideal balance state (the vector sum of the three is zero), thereby reducing the viscosity of the drill string, stabilizing the WOB, and increasing the ROP.

[0091]The basic principle of the present invention is to make the surface system (top drive or turntab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com