Sisal processing method and sisal scraping device thereof

A processing method, sisal technology, applied in textiles and papermaking, mechanical treatment, fiber mechanical separation, etc., can solve problems affecting fiber extraction rate and straight fiber output rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

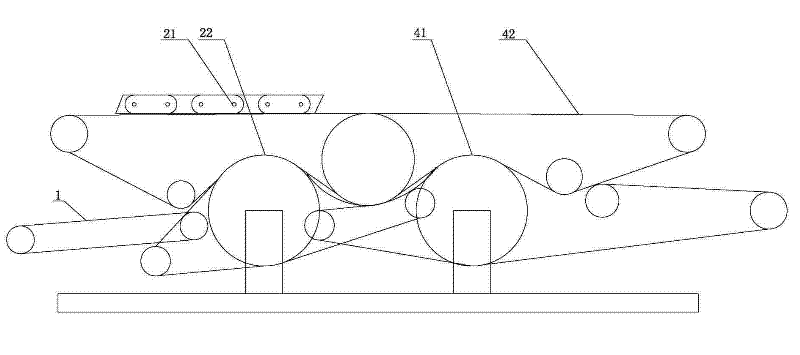

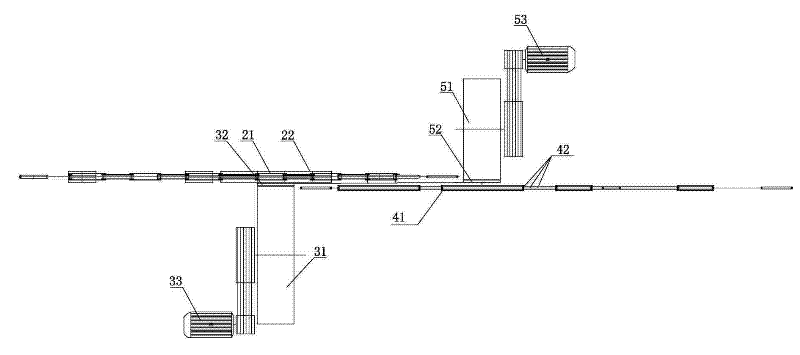

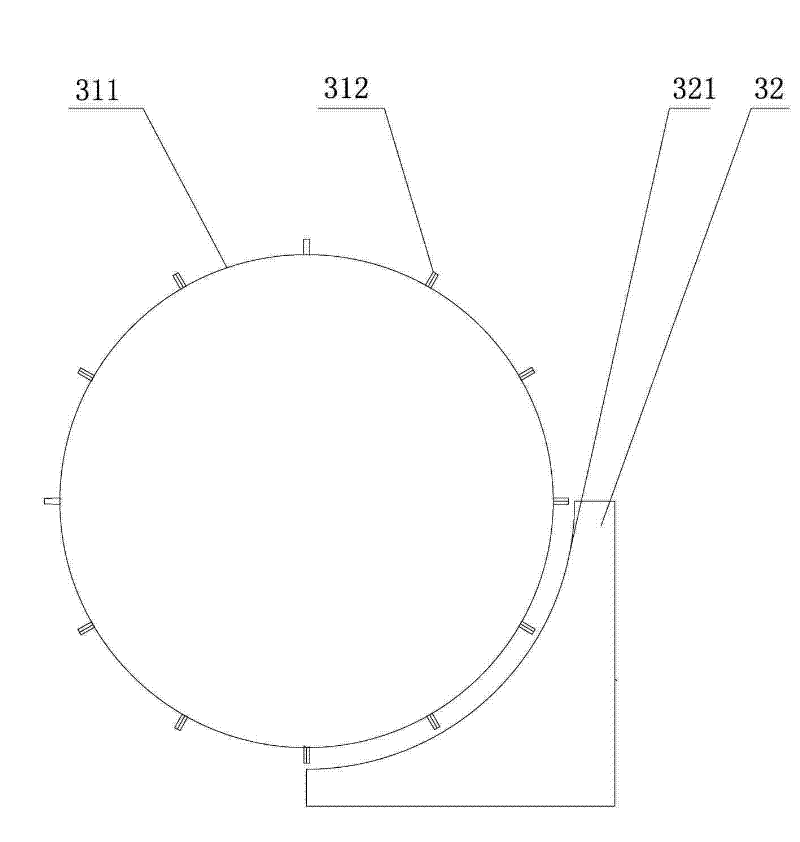

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0024] Sisal processing method concrete process of the present invention is as follows:

[0025] 1. Separate the harvested sisal leaves from the base and the tip and tie them tightly, and send them to the factory for processing according to the grade of sisal leaves;

[0026] 2. First-level hemp discharge and conveying. According to the set processing capacity of 20-25 tons per hour, set the required weight of sisal leaves per minute and per meter to convey, and arrange the hemp handles one by one without leaving intervals;

[0027] 3. Secondary hemp discharge and conveying. The sisal leaves arranged in bundles are conveyed by the first-stage hemp row and stretched and thinned by the speed difference of the two conveyor belts;

[0028] 4. Even conveying. The sisal leaves transported by the second-level hemp row are e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com