Device for preparing non-woven fabric product continuously with electrostatic spinning method

An electrospinning method and electrospinning technology are applied in the field of devices for preparing ultrafine fibers, which can solve the problems of thick fiber diameter, high manufacturing difficulty and high maintenance cost, and achieve uniform fiber diameter, reduced processing difficulty and large void ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

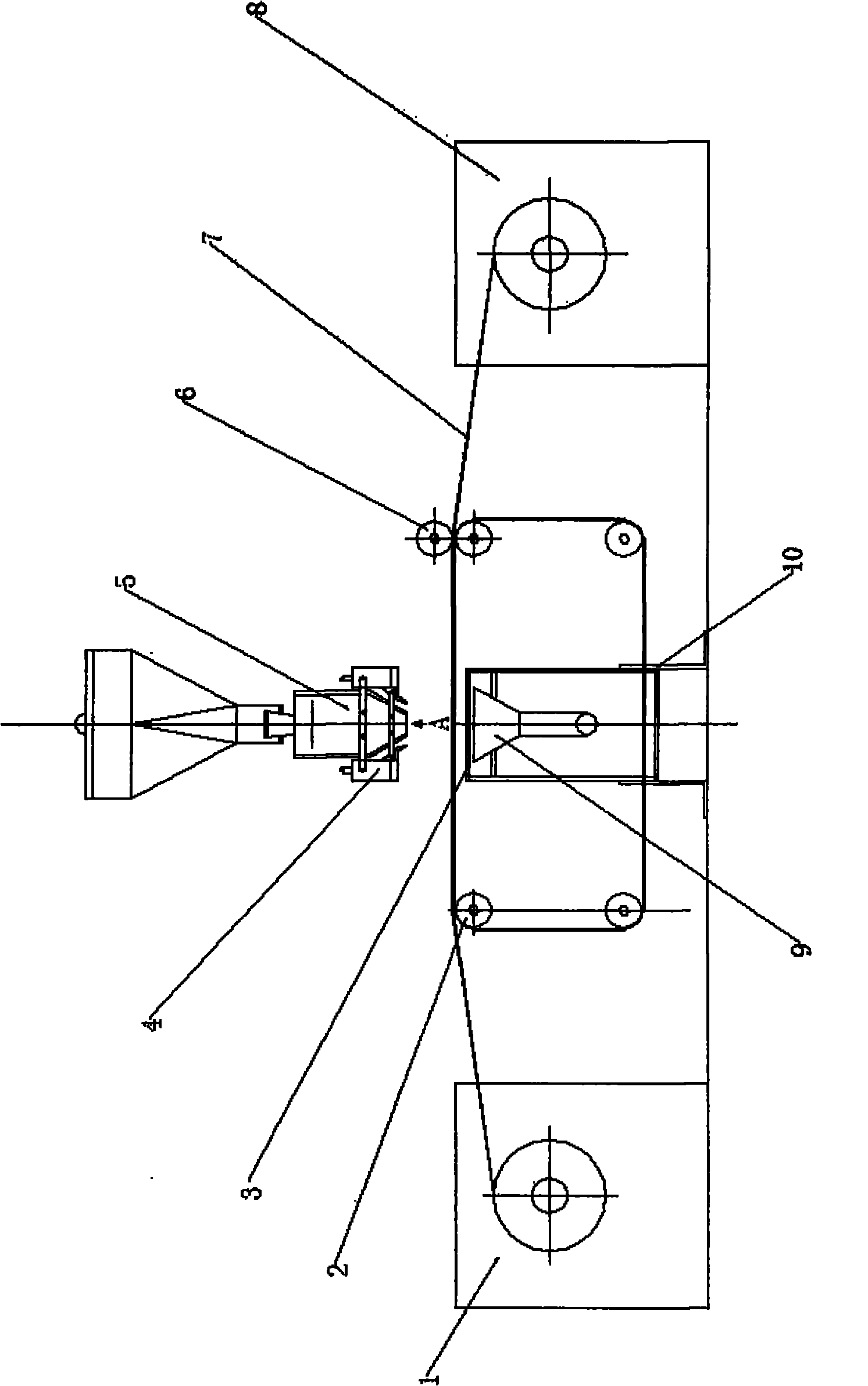

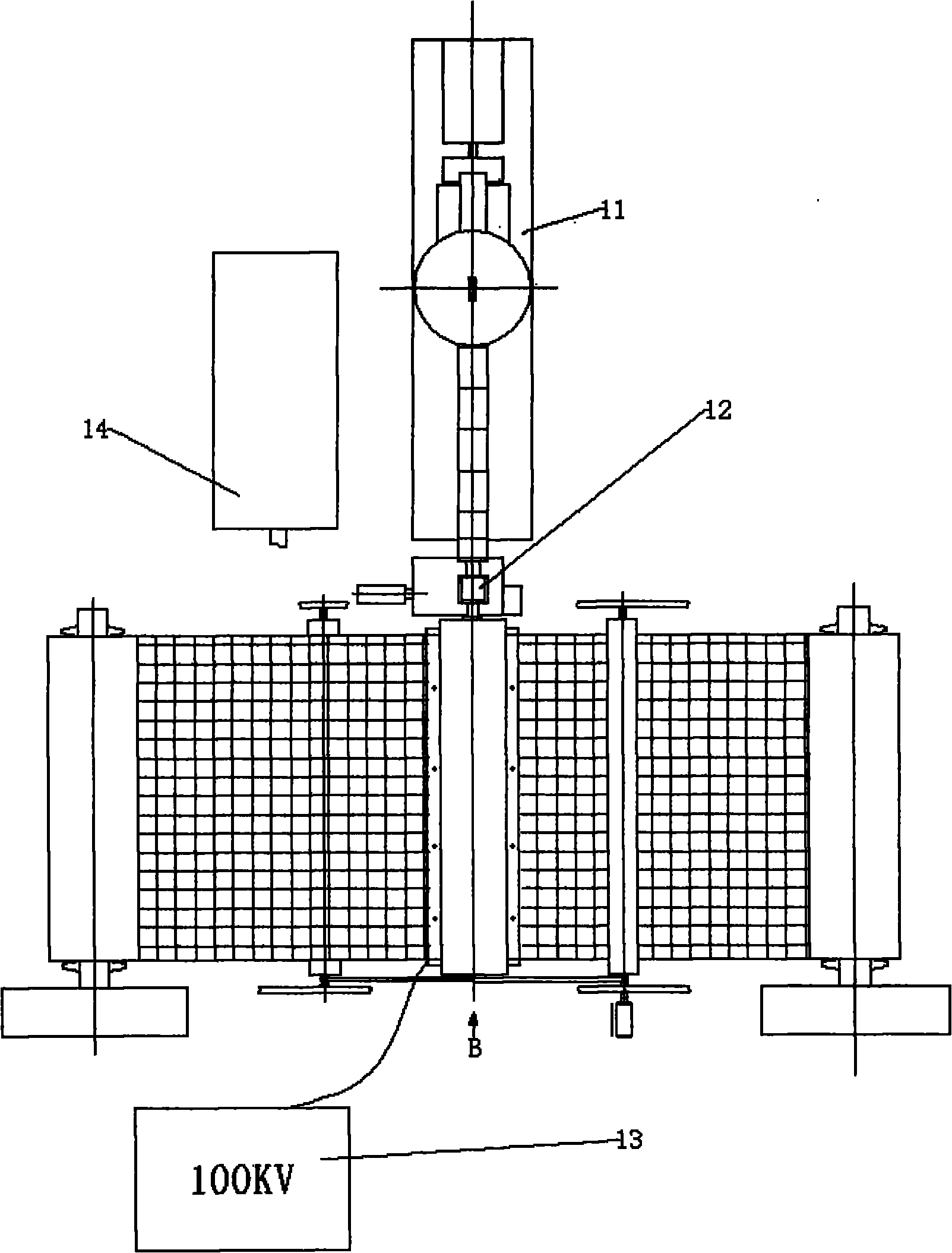

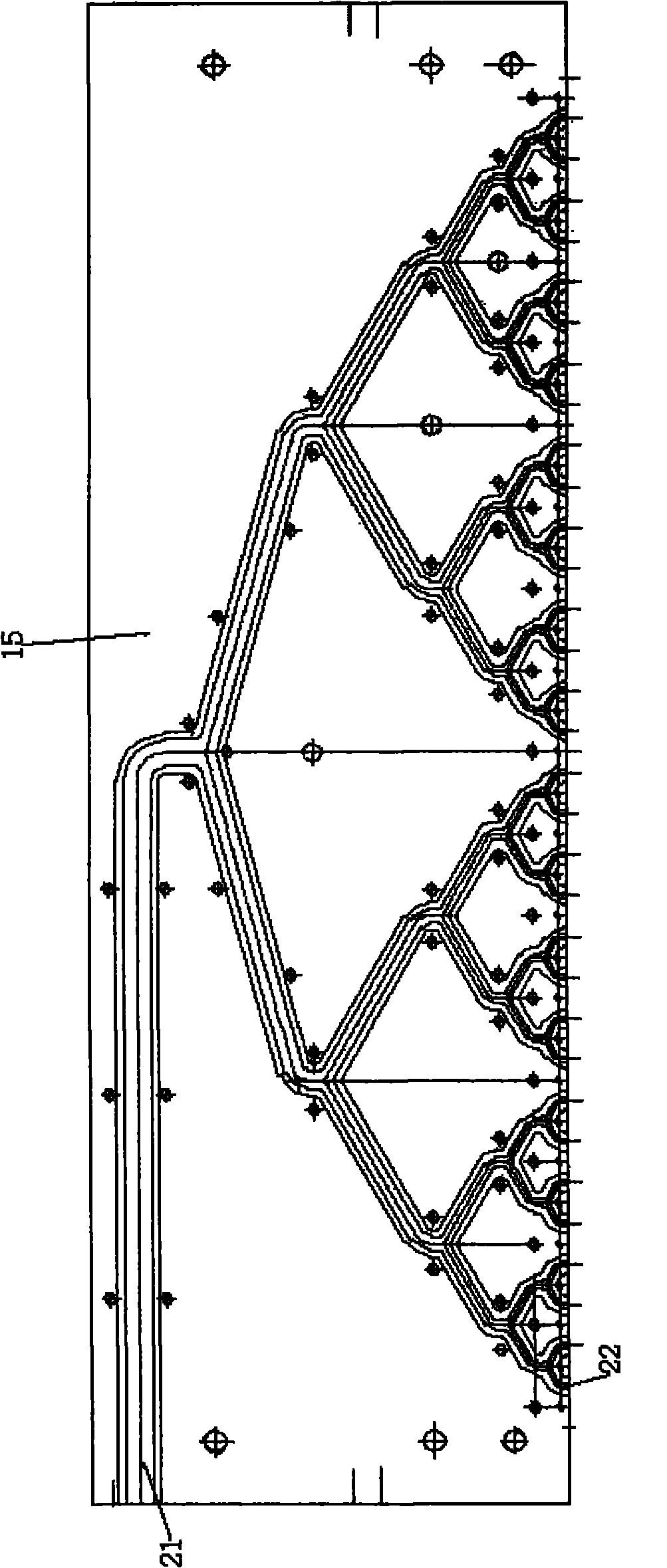

[0026] The present invention proposes a device for continuously preparing non-woven fabric products by melt electrospinning method, such as figure 1 and figure 2 As shown, the device mainly includes: a melt conveying device, a melt metering pump 12, an electrospinning die head 5, a die head temperature control device, a high-voltage static electricity generating device 13, a collecting device and a support. In the figure, the melt delivery device is an extruder 11, and the die head temperature control device is composed of a heating rod 20, a temperature sensor 19 and a control element. After the material is fed into the extruder 11, it is plasticized and homogenized into a uniform molten state by the extruder 11, and is transported to the melt metering pump 12. The flow and velocity of the molten material are controlled by the melt metering pump 12, which ensures that the fiber Stability of diameter and output. The molten material is transported to the hot runner inlet 21 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com