Continuous pulping method for cotton stalk natural color chemomechanical pulp

A chemical-mechanical, natural technology, applied in pulp beating/refining methods, pulping with inorganic alkali, pulping of cellulose raw materials, etc., can solve problems such as low pulping yield, low refining concentration, and large power consumption , to achieve the effect of improving slurry quality, reducing impurity content and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes.

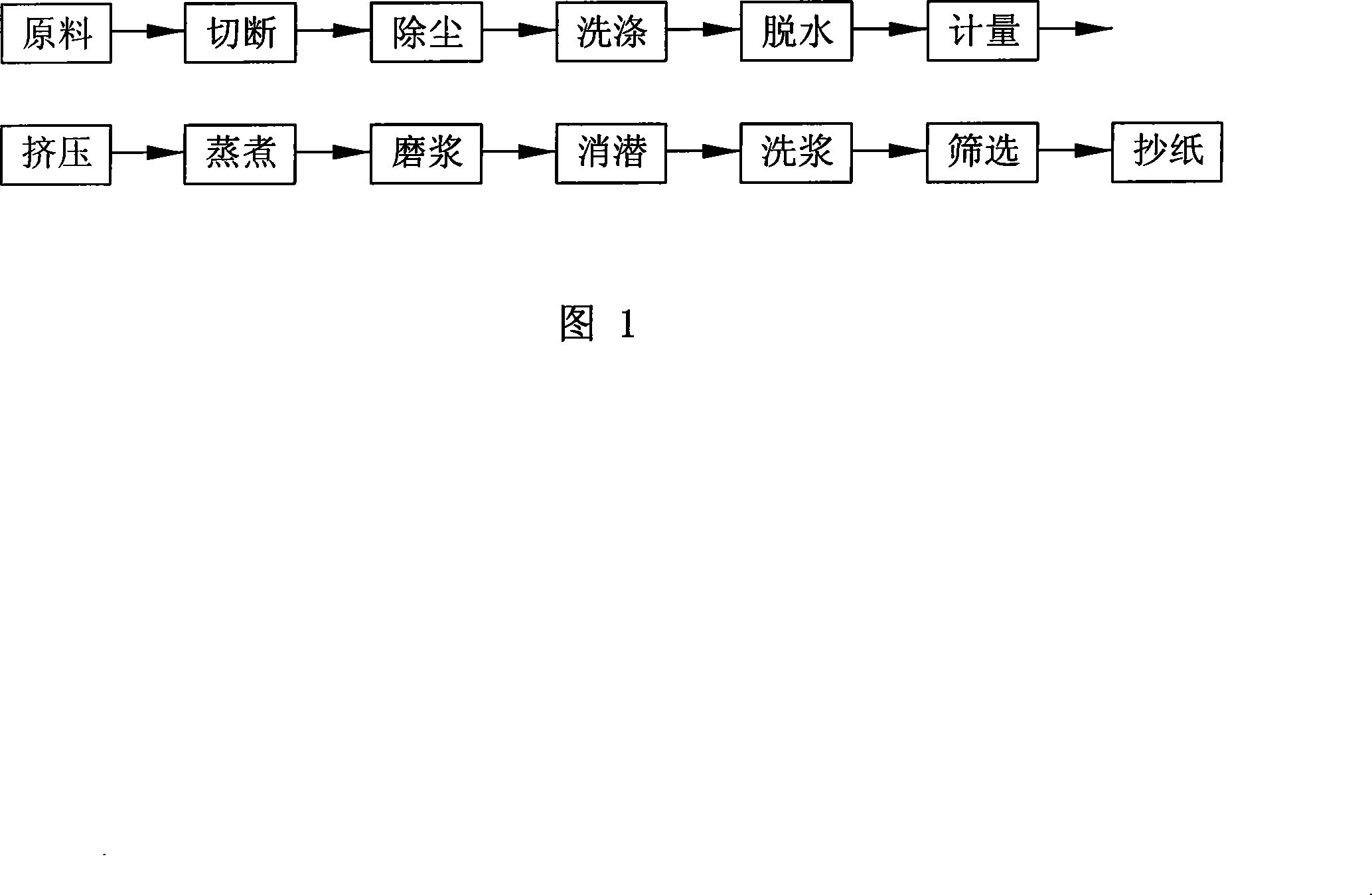

[0024] A method for continuous pulping of cotton stalk natural color chemical mechanical pulp, comprising the following steps: cotton stalk raw materials are cut by a cotton stalk crusher into pieces of ≤40mm; qualified raw materials are sent to a silo after dedusting by a dust collector, and are stored in the silo After that, it is sent to the double-drum washer for washing. After the heavy impurities are separated under the action of the washing water, it enters the oblique spiral dehydrator to remove the washing water; the clean raw materials after dehydration are sent to the pin drum meter, and the raw material is sold to the drum meter. After metering, it is extruded and dehydrated by the screw feeder to form a tight plug and then sent to the horizontal tube continuous steamer; in the horizontal tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com