Biological pulping method adopting crop straw and papermaking pulp

A technology for crop straw and biological pulping, which is used in papermaking, textiles and papermaking, and cellulose treatment with microorganisms/enzymes to reduce energy consumption, reduce emissions, and improve pulp yield and whiteness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

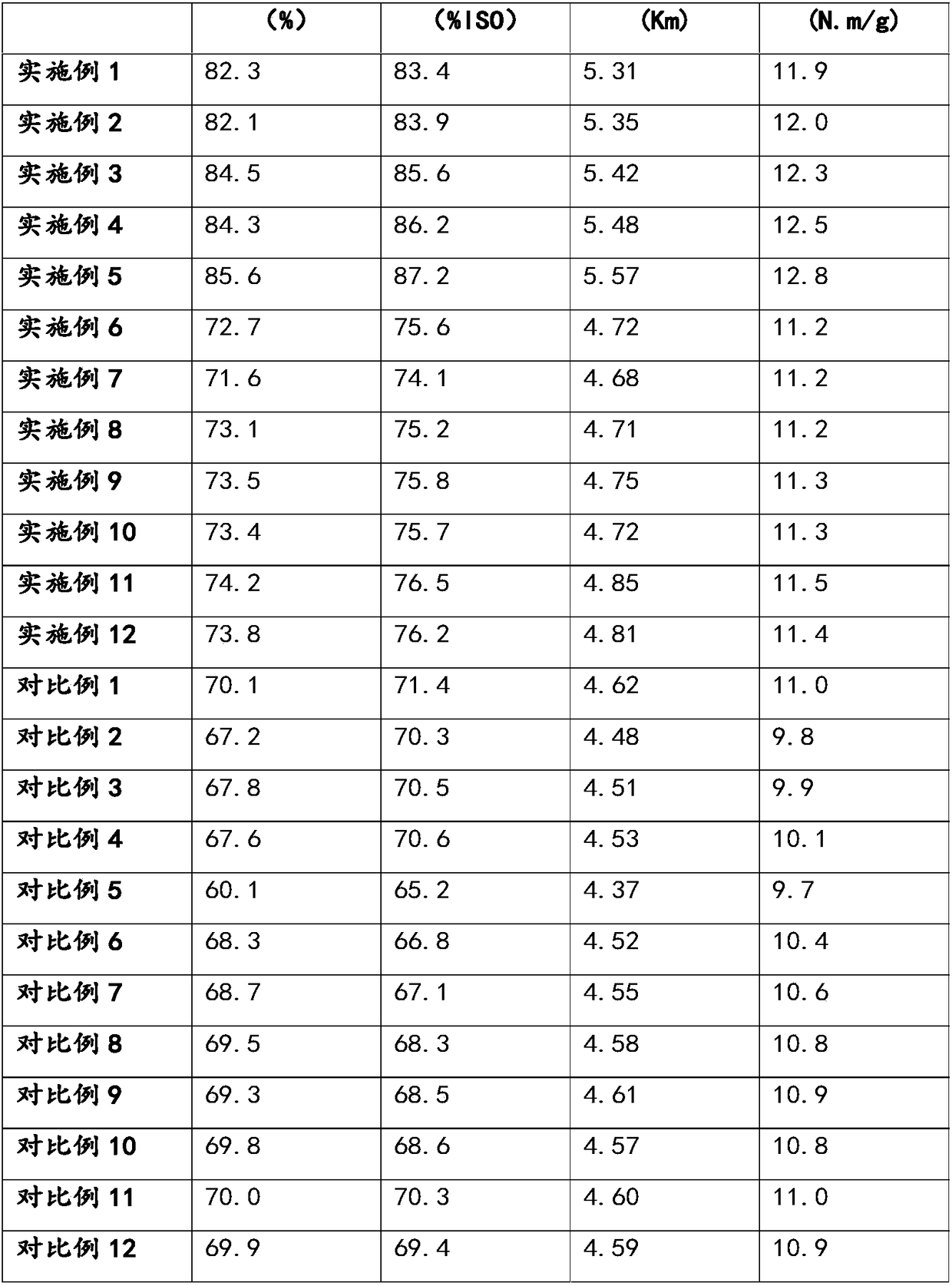

Examples

Embodiment 1

[0087] This embodiment provides a method for biological pulping of crop straws, comprising the following steps:

[0088] (a 1 ) cutting crop straws into sections with a length of 30-40 mm, then soaking the cut crop straws in water for 2 hours, and then squeezing the water to obtain crop straw hydrolyzed material with a moisture content of 2-30%;

[0089] (a 2 ) subjecting the crop straw hydrolyzed material to a bioenzyme treatment at a temperature of 50° C. for 3 hours to obtain a coarse crop straw material;

[0090] A compound biological enzyme preparation is used for one-time biological enzyme treatment, and the treatment temperature is 50°C to obtain a coarse pulp of crop straw;

[0091] (b) Grinding and separating the coarse diameter of the crop straw to obtain the crop straw

[0092] (c) subjecting the crop straw grinding slurry to a secondary treatment with a microbial agent at 50° C., and the secondary treatment time is 20 minutes, to obtain a fine slurry of crop str...

Embodiment 2

[0097] This example provides a biopulping method for crop straws. The difference between this example and Example 1 is that in the compound biological enzyme preparation, lignin peroxidase, xylanase, laccase, pectin Enzymes and beating enzymes are 3:2:2:2:2.

Embodiment 3

[0099]This example provides a biopulping method for crop straws. The difference between this example and Example 1 is that in the compound biological enzyme preparation, lignin peroxidase, xylanase, laccase, pectin Enzymes and beating enzymes are 2:1:1:1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com