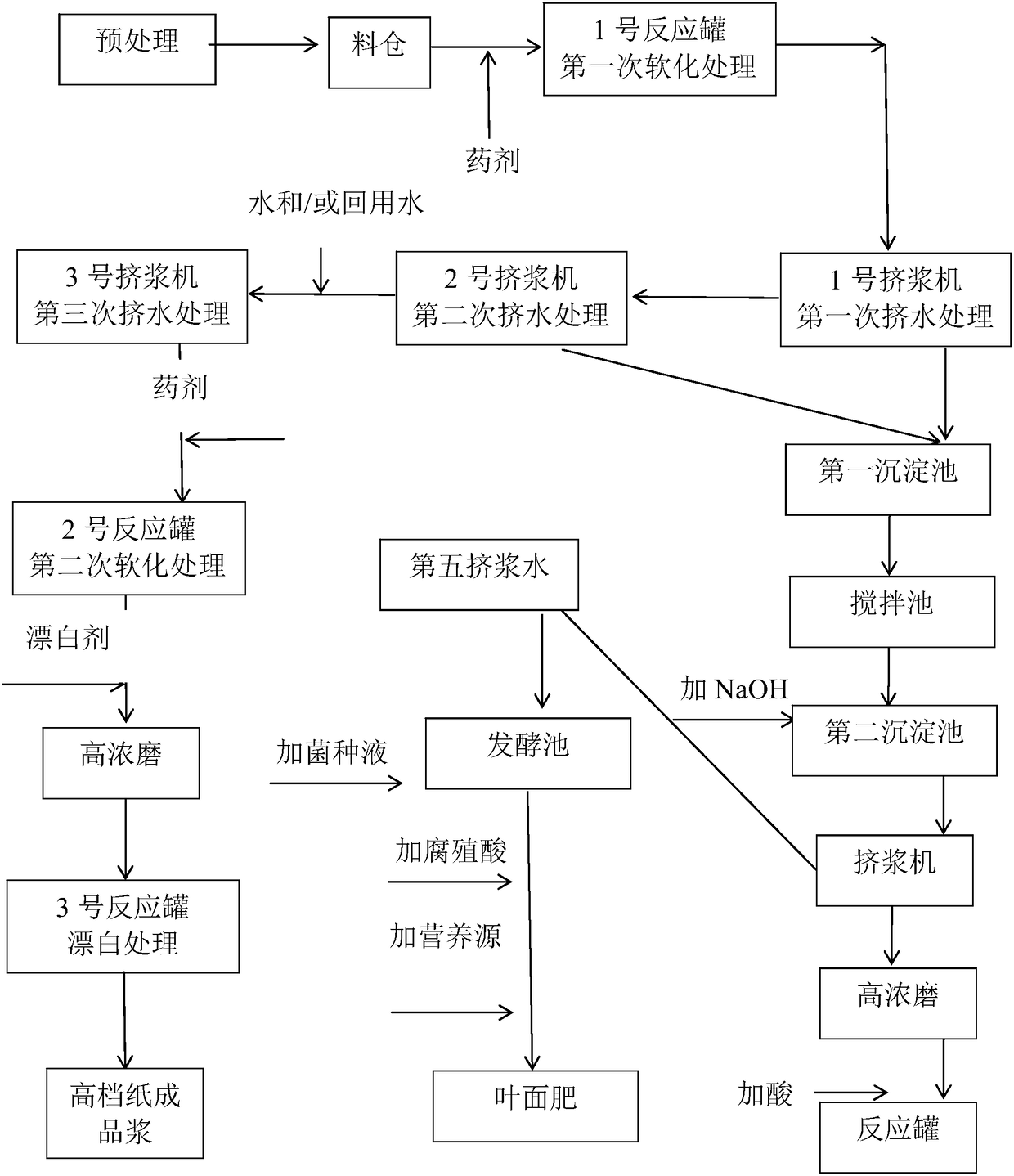

[0005] The traditional papermaking process is to process the papermaking raw materials through pulping, modulation, papermaking,

processing and other main

processing steps. Among them, pulping is the first step and the most critical step in papermaking. The pulping process is to remove the pulping raw materials. The process of

lignin; the removal process is mainly divided into

chemical pulping method, mechanical pulping method and semi-

chemical pulping method,

chemical pulping method is the most widely used production method; it mainly includes crushing-cooking-alkali

softening- Squeezing-washing-bleaching and other operations; the chemical pulping method is to use chemical liquid to continuously cook the flakes in a device that is fed with high-temperature steam above 150°C, so that the

lignin in the pulping raw materials can be produced with chemical reagents at high temperature. The reaction produces water-soluble matter, which is separated from the

fiber into a slurry; although chemical pulping retains the natural length of the

fiber and removes most of the

lignin, the yield of the slurry is low and the

pollution is large, and in the

cooking process, due to

chemical agents The addition of the prepared pulp has an unpleasant smell and a

bitter taste, and a large amount of

black liquor will be produced in the subsequent squeezing and washing process

[0006]

Black liquor contains a large amount of

suspended solids, organic pollutants and toxic substances, of which about 30-35% are inorganic substances, and the main components are

sodium hydroxide,

sodium carbonate,

sodium sulfide,

sodium sulfate and other sodium salts combined with organic substances ; It also contains 65-70% organic substances, the main components are lignin, resin,

starch and low-molecular compounds, etc. If the

black liquor is directly discharged into the

water body, it will cause serious

pollution, such as containing a large amount of

fiber,

pigment and inorganic Salt papermaking

wastewater will turn the water black and have a special stench; the

biochemical oxygen demand (BOD) of papermaking black liquor containing high concentrations of organic pollutants can be as high as 5000-40000g / L, which will consume a large amount of dissolved water.

Oxygen affects the

water quality; a large amount of alkaline substances in the black liquor will cause the pH value of the water to rise sharply and destroy the balance of the

water environment[0007] Traditional alkali

recovery technology equipment is complex and requires a large amount of investment. It is reported that a set of alkali

recovery equipment generally requires an investment of more than 30 million yuan, and its daily operating costs are also relatively high. It is as high as 2671 yuan /

ton of alkali, while the market price of

sodium hydroxide is only 1800 yuan. Therefore, most of our enterprises are unable to carry out alkali recovery at present, but directly

discharge the black liquor or directly

discharge it after

dilution, causing environmental

pollution, especially in water areas. extreme pollution

[0008] At present, there are relevant reports on the preparation of fertilizers from papermaking black liquor, and they have not been effectively promoted. Not only that, but there are also some problems in these technical solutions: (1) the cost is high; (2) the quality of the prepared fertilizer is poor , poor fertilizer efficiency; (3) it is necessary to add other

nutrient sources, and its consumption is equivalent to that of fertilizers prepared by other methods in the prior art; (4) there are few utilization methods and a single variety

[0011] Disclosed in

Chinese patent CN101486604A is a kind of

fulvic acid foliar fertilizer of

ammonium method grass pulp black liquor as raw material, and this foliar fertilizer is to use imonium method grass pulp black liquor as raw material, and in the preparation process of described foliar fertilizer , using two consecutive

flash evaporation-five-effect

evaporation technology to concentrate the black liquor of

ammonium method grass pulp, although in order to improve the

utilization rate of

heat energy, it adopts the method of steam recycling, but it is inevitable to introduce additional energy; not only that , the equipment for this process is in a high temperature state for a long time, and a large amount of money is also required for equipment wear and maintenance

Moreover, this preparation process only adds soluble trace elements to the concentrated

ammonium method

straw pulp black liquor, and does not do any treatment to harmful substances and

suspended solids in the imonium method

straw pulp black liquor, which are still retained in the obtained

Fulvic acid foliar fertilizer; plants that absorb this kind of foliar fertilizer may also deposit some toxic and harmful substances and elements in the body while supplementing nutrients

Login to View More

Login to View More