Sea-buckthorn pulping method and sea-buckthorn pulp thereof

A sea buckthorn and pulping technology, applied in textiles and papermaking, raw material separation, papermaking, etc., can solve the problems of unutilized branches and waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

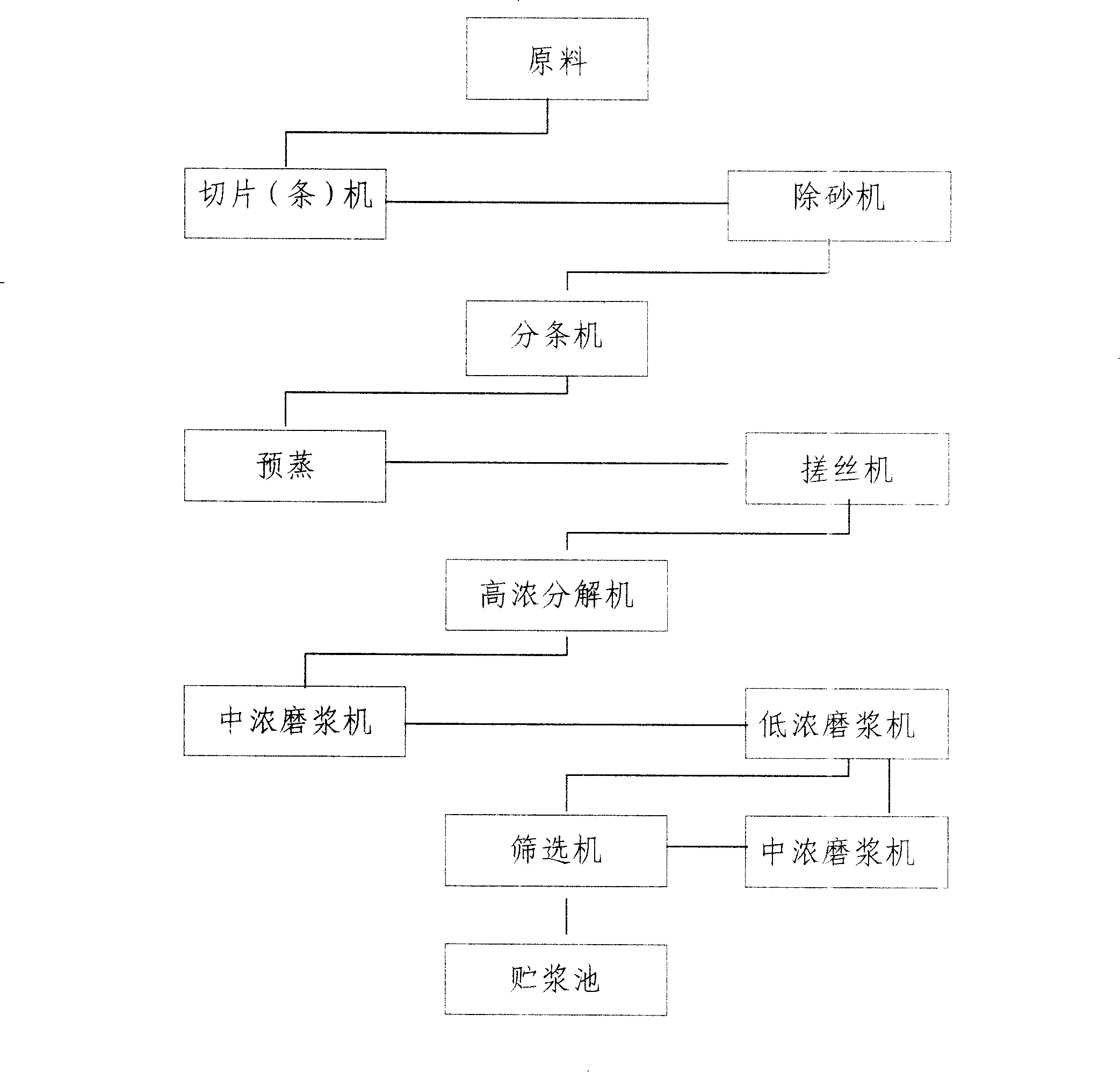

[0028] according to figure 1 The process flow chart shown is for seabuckthorn pulping. First cut the seabuckthorn wood into 15mm seabuckthorn slices through a slicer, and then remove the sand dust and impurities in the seabuckthorn through a sand remover.

[0029] The material is decomposed into thin strips by a slitting machine, and then 1kg of steam is introduced for 3 hours of softening and pre-steaming treatment; then it is sent to a thread rolling machine for thread separation and kneading, and after crushing and rubbing, it is formed into coarse strips. Fibrous;

[0030] Finally, three-stage refining is carried out, which are: first-stage refining treatment by high-consistency decomposing machine, the concentration of slurry is 35%; secondary refining treatment by medium-consistency refining machine, slurry concentration is 70%; low-consistency refining The pulp machine is subjected to three-stage refining treatment, and the slurry concentration is 90%. After the thre...

Embodiment 2

[0033] First cut the seabuckthorn branches into 20mm seabuckthorn branch sections by a slicer, and then remove the sand dust in the seabuckthorn by a sand remover.

[0034] Then the material is decomposed into thin strips by a slitting machine, and then 2 kg of steam is introduced for 2 hours of softening and pre-steaming treatment; then it is sent to a thread rolling machine for thread separation and kneading, and after crushing, rubbing and separation, coarse strips are formed. Fibrous;

[0035] Finally, three-stage refining is carried out, which are: first-stage refining treatment by high-consistency decomposing machine, the concentration of slurry is 40%; secondary refining treatment by medium-consistency refining machine, slurry concentration is 60%; low-consistency refining The pulp machine is subjected to three-stage refining treatment, and the slurry concentration is 80%. After the third stage of refining, it is screened and sent to the pulp storage tank for standby, ...

Embodiment 3

[0038] First cut the seabuckthorn wood into 18mm seabuckthorn slices through a slicer, and then remove the sand dust in the seabuckthorn through a sand remover.

[0039] Then the material is decomposed into thin strips by a slitting machine, and then 2 kg of steam is introduced for 2 hours of softening and pre-steaming treatment; then it is sent to a thread rolling machine for thread separation and kneading, and after crushing, rubbing and separation, coarse strips are formed. Fibrous;

[0040] Finally, three-stage refining is carried out, which are: first-stage refining treatment by high-consistency decomposing machine, the concentration of slurry is 38%; secondary refining treatment by medium-consistency refining machine, slurry concentration is 65%; low-consistency refining The pulp machine is subjected to three-stage refining treatment, and the slurry concentration is 85%.

[0041] The pulp yield of the slurry was 76.5% after being washed by conventional methods. After p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Tightness | aaaaa | aaaaa |

| Ring pressure index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com