Li-ion positive electrode slurry and preparation method thereof

A cathode slurry, lithium ion technology, used in battery electrodes, electrical components, circuits, etc., can solve the problems of poor slurry conductivity, poor slurry stability, and poor slurry uniformity, and achieve sedimentation. Small, good pulping effect, good uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

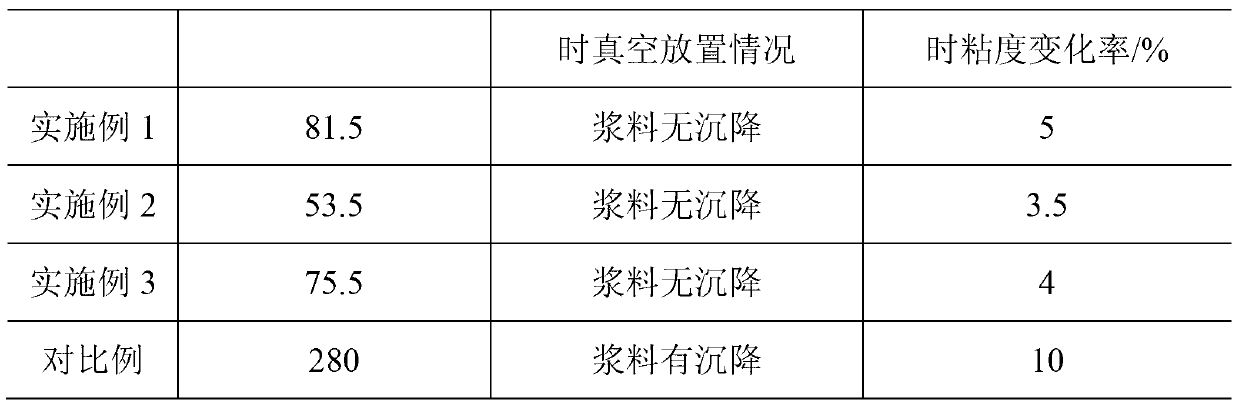

Embodiment 1

[0032] 1) Weigh lithium iron phosphate, polyvinylidene fluoride, Super-P material and KS-6 respectively according to the mass ratio of 90:7:2:1;

[0033] 2) Dry powder mixing:

[0034] Clean and dry the slurry tank of the planetary mixer, add lithium iron phosphate, Super-P material and KS-6, then dry mix at a revolution speed of 5rpm and a stirring speed of 10rpm for 30min, and keep the stirring temperature at 20-40°C, and according to the situation, the stirring blade and the slurry tank need to be scraped in time to make the obtained dry powder mixture evenly mixed; during the stirring process, the lithium iron phosphate, Super-P material and KS are being mixed from the slurry tank -6 and 10 samples were randomly sampled from all directions in the inorganic conductive agent, and the powder resistance values of these 10 samples were tested respectively. The deviation of the powder resistance value of each sample was less than 5%. At this time, it was considered to be unifo...

Embodiment 2

[0044] Step 1) to step 2) are the same as step 1) to step 2) in the embodiment;

[0045] 3) Step-by-step slurry preparation process:

[0046] According to the mass ratio of 8:100, dissolve polyvinylidene fluoride into N-methylpyrrolidone at 20-40°C to obtain PVDF colloidal liquid; divide PVDF colloidal liquid into four parts, and the first part of PVDF colloidal liquid Accounting for 32% of the total mass of PVDF jelly, the second PVDF jelly accounts for 15% of the total PVDF jelly, the third PVDF jelly accounts for 28% of the total PVDF jelly, and the fourth PVDF Colloidal liquid accounts for 25% of the total mass of PVDF colloidal liquid;

[0047] Add the first part of PVDF colloidal liquid to the dry powder mixture, and then stir at a revolution speed of 15rpm and a stirring speed of 28rpm at 20-40°C for 30min to make it uniform, and obtain a mixed slurry A; wherein, during the stirring process, according to the situation The stirring paddle and the slurry tank are scrape...

Embodiment 3

[0054] Step 1) to step 2) are the same as step 1) to step 2) in the embodiment;

[0055] 3) Step-by-step slurry preparation process:

[0056] According to the mass ratio of 8:100, dissolve polyvinylidene fluoride into N-methylpyrrolidone at 20-40°C to obtain PVDF colloidal liquid; divide PVDF colloidal liquid into four parts, and the first part of PVDF colloidal liquid Accounting for 35% of the total mass of PVDF gel, the second PVDF gel accounts for 18% of the total mass of PVDF gel, the third PVDF gel accounts for 30% of the total mass of PVDF gel, and the fourth PVDF Colloidal liquid accounts for 17% of the total mass of PVDF colloidal liquid;

[0057] Add the first part of PVDF colloidal liquid to the dry powder mixture, and then stir at 20-40°C at a revolution speed of 20rpm and a stirring speed of 35rpm for 40min to make the mixed slurry A uniform; The stirring paddle and the slurry tank are scraped in good time so that there is no dry powder in the obtained mixed slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com