Soymilk machine cutter detection method

A detection method and technology of soymilk machine, which are applied in the testing of machine/structural components, measuring devices, household appliances, etc., can solve the problems of loose screws or concave-convex buttons, easy to cause danger, falling off, etc., to improve the crushing effect and pulp output. effect, the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

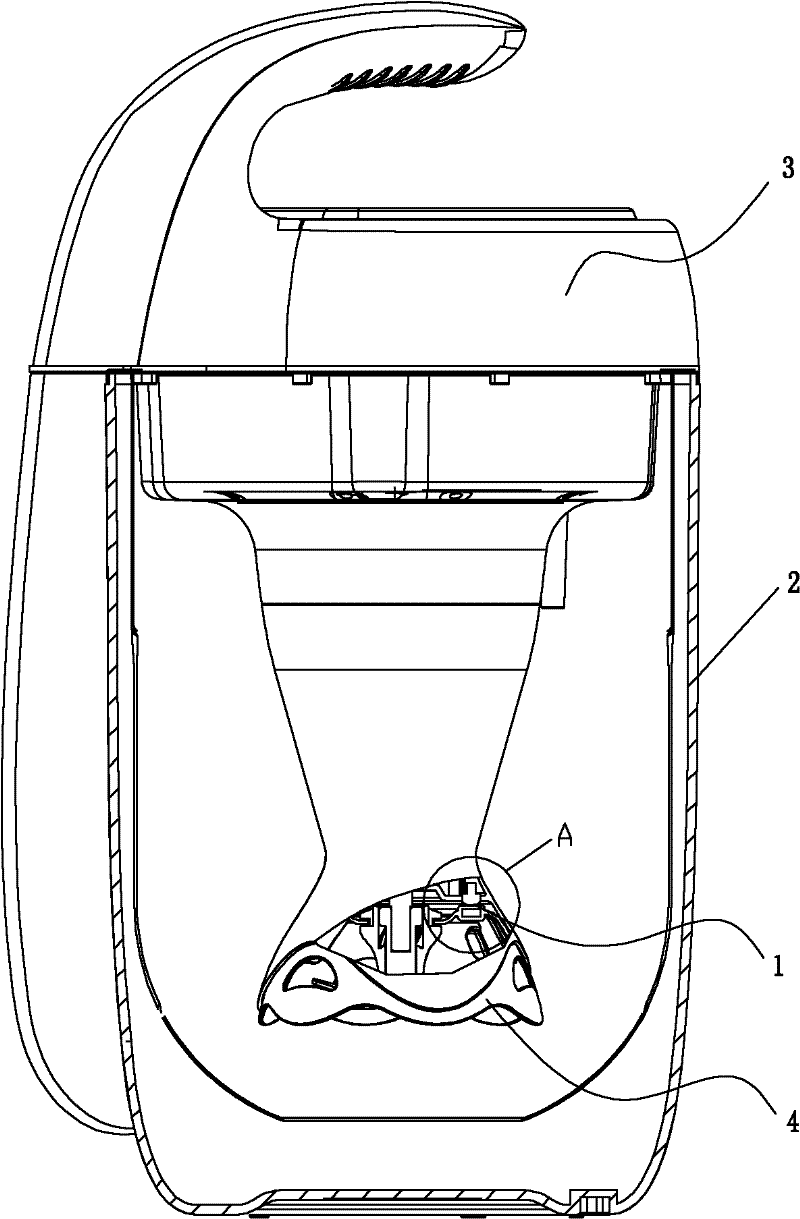

[0035] See attached Figure 1~7 , a kind of soya-bean milk maker tool detection method, comprises the following steps:

[0036] a. Start the pulping process;

[0037] b. Replace the tool;

[0038] c. Select the corresponding pulping program and start it;

[0039] d. In the detection stage, check whether it is the corresponding pulp making program, if yes, enter the next step, if not, report an error, and at the same time, the program returns to the b. tool replacement stage;

[0040] e. End tool inspection.

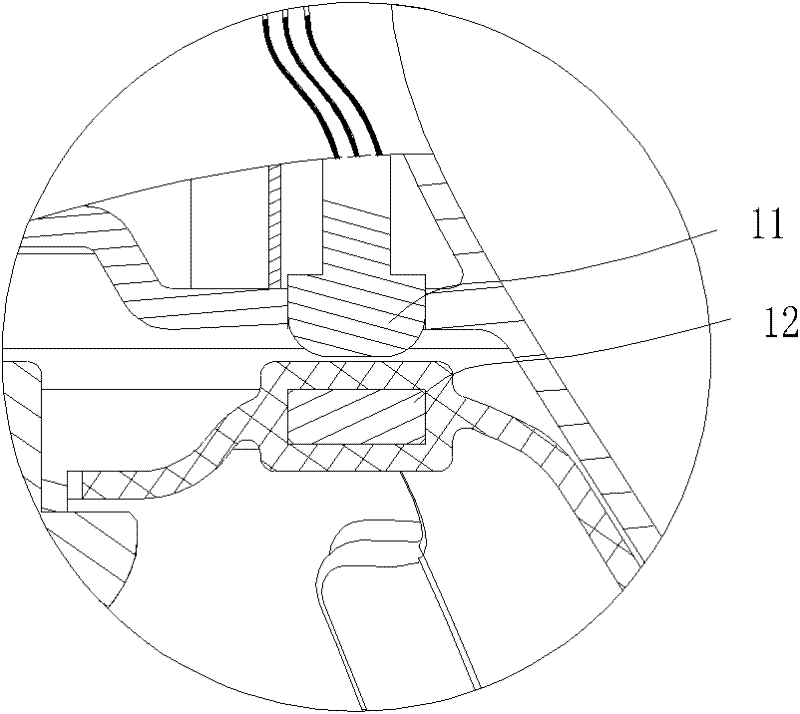

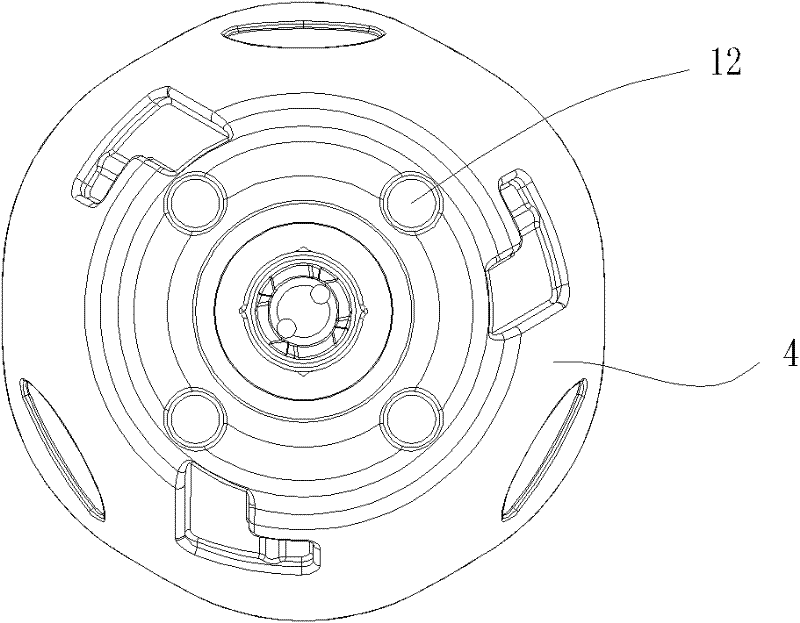

[0041] The detection stage is to detect the I / O port, feed back the retrieved signal to the MCU, and compare it with the corresponding program, if the comparison is consistent, the program continues, otherwise, the program alarm prompts, and the program returns to b. Tool stage. The number of the I / O ports is 5. Specifically, the I / O port can be set as a dry bean and soymilk knife detection port, a wet bean soymilk knife detection port, a rice paste knife detection ...

Embodiment 2

[0047] When the detection probe 11 is a magnetic reed switch, it is used to detect the presence or absence of magnetism, and more than one magnetic reed switch is arranged in the extension body of the lower cover of the machine head, and a magnet is arranged on a corresponding position on different cutters respectively. The reed switch detects the magnetism of the corresponding position of the tool assembly, which is used for the program to judge whether the installed tools are consistent. Others are the same as embodiment one.

Embodiment 3

[0049]One or more tact switches are arranged in the extension body of the lower cover. Concave-convex points are arranged at different positions on the tool. When the tact switch is pushed up by the convex points on a certain tool, the corresponding program can run normally. Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com