Additive for anode material of lithium ion battery, preparation method of additive, positive electrode material containing additive and lithium ion battery

A lithium-ion battery and positive electrode material technology, which is applied in the direction of battery electrodes, electrolyte battery manufacturing, secondary batteries, etc., can solve the problems of affecting battery performance, poor cycle performance of lithium-ion batteries, and poor pulping and sheeting effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of the positive electrode material additive for lithium ion batteries, the method comprising the following steps:

[0033] S1, using a silane coupling agent to modify the surface of the inorganic lithium salt to obtain a silane coupling agent-modified inorganic lithium salt;

[0034] S2. After fully dispersing the conductive carbon material in an organic solvent, mix it with the low melting point polymer and the inorganic lithium salt modified by the silane coupling agent in step S1, and heat until the organic solvent is completely volatilized, so that the low melting point polymer and the conductive carbon The material is coated on the surface of the inorganic lithium salt, and a composite material with a core-shell structure is obtained after drying.

[0035] According to the preparation method of the lithium ion battery cathode material additive of the present invention, preferably, the step S1 includes adding ...

Embodiment 1

[0074] (1) Prepare silane coupling agent solution according to the ratio of 20% silane coupling agent KH550, 72% ethanol, and 8% water;

[0075] (2) Take 50g LiNi 0.8 co 0.15 al 0.05 o 2 Add to the aqueous solution of ethanol and heat to 60°C to obtain a mixed solution;

[0076] (3) Slowly add 15ml of the silane coupling agent solution in step (1) to the mixed solution in step (2), and stir at 200rad / min until the solvent is completely evaporated. Put the remaining material in a vacuum drying oven at 150°C for drying, soak in ethanol after drying, wash, and centrifuge to obtain LiNi modified by silane coupling agent 0.8 co 0.15 al 0.05 o 2 ;

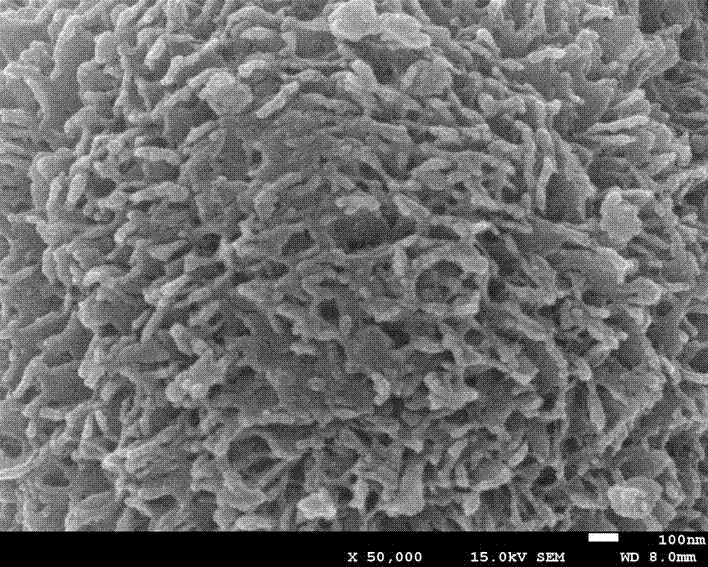

[0077] (4) Add 0.3 g of carbon nanotubes with an average particle size of 150 nm into 100 ml of decahydronaphthene for ultrasonic dispersion, then add it into a 500 ml three-necked round bottom flask, heat to 100 ° C, and stir at 200 rad / min;

[0078] (5) adding 10 g molecular weight to the mixed solution of step (4) is 3000 low...

Embodiment 2

[0081] The same treatment method as in Example 1, except that 0.4 g of carbon fibers with an average particle diameter of 500 nm was added in step (4) instead of carbon nanotubes to prepare lithium-ion battery cathode material additive A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com