Turbulent flow identification method of food processor

A technology of food processors and turbulence devices, which can be used in household appliances, applications, kitchen utensils, etc. It can solve problems such as poor crushing, materials that cannot be hit by blades, and burns to users, so as to reduce the probability of detection misjudgment and solve the detection temperature. Deviation, the effect of improving the recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

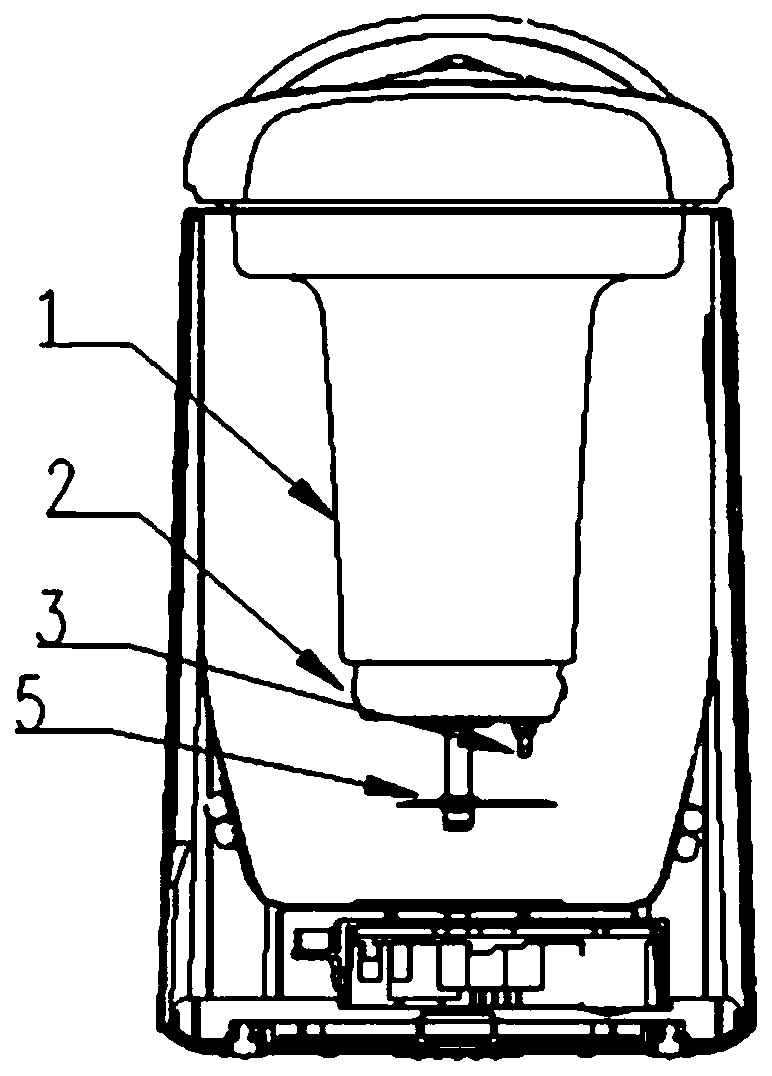

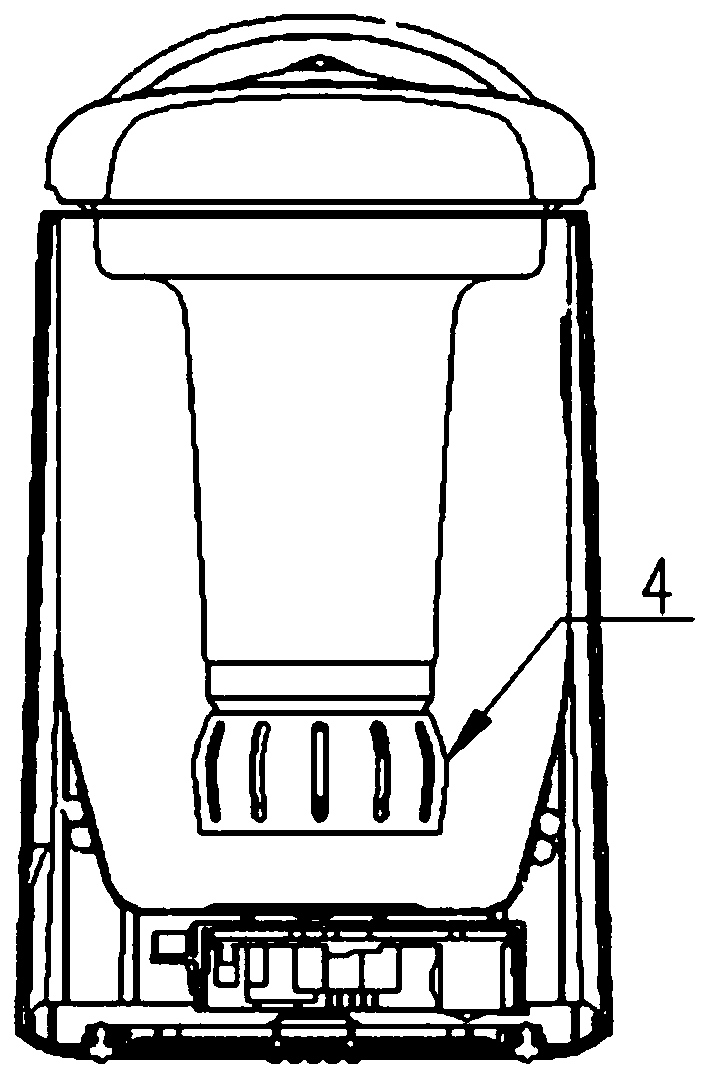

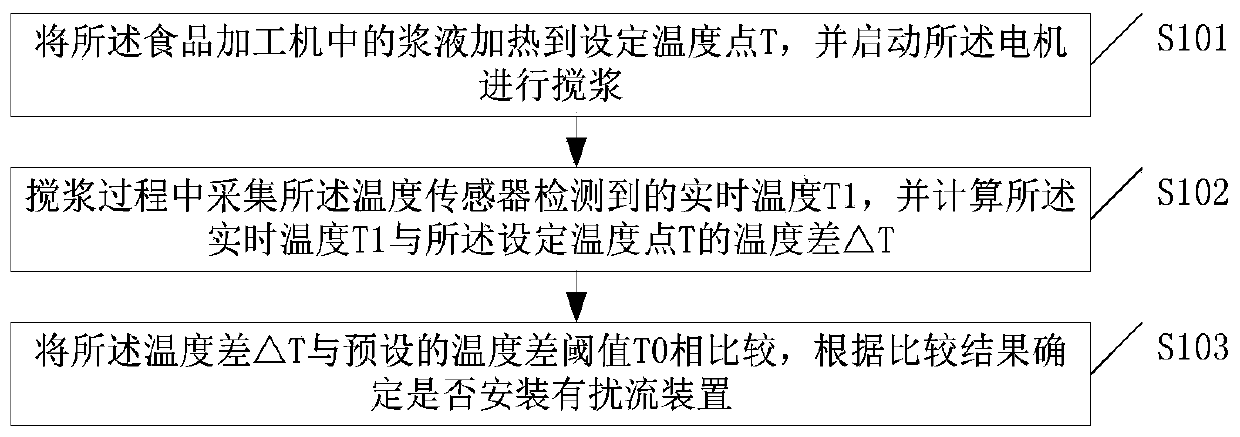

[0042] An embodiment of the present invention provides a method for identifying a spoiler for a food processor, as shown in Figure 1(a) and Figure 1(b), the food processor may include a motor 5 and a machine head 1, the machine A temperature sensor 3 may be provided at the fixed position 2 of the turbulence device 4 on the head 1; as figure 2 As shown, the method may include S101-S103:

[0043] S101, heating the slurry in the food processor to a set temperature point T, and starting the motor to stir the slurry;

[0044] S102. Collect the real-time temperature T1 detected by the temperature sensor during the mixing process, and calculate the temperature difference ΔT between the real-time temperature T1 and the set temperature point T;

[0045] S103. Comparing the temperature difference ΔT with a preset temperature difference threshold T0, and determining whether a spoiler is installed according to the comparison result.

[0046] In an exemplary embodiment of the present inv...

Embodiment 2

[0057] On the basis of Example 1, this example provides an example of a specific heating method for heating the slurry in the food processor to the set temperature T.

[0058] In an exemplary embodiment of the present invention, the heating the slurry in the food processor to the set temperature point T may include: heating the slurry to the set temperature point T with full power.

[0059] In an exemplary embodiment of the present invention, the heating mode set by the system can be a full power heating mode, so as to heat the slurry to the set temperature point T in the shortest time, avoiding the situation of uniform temperature if the low power is heated for a long time lead to misjudgment.

Embodiment 3

[0061] On the basis of the first or second embodiment, this embodiment provides an embodiment in which the working power of the motor is detected during the pulping process as a supplementary basis for judging whether the turbulence device is installed.

[0062] In an exemplary embodiment of the present invention, the method may further include: after determining that the flow turbulence device is not installed, judging again whether the flow turbulence device is installed according to the operating frequency of the motor during the pulping process.

[0063] In an exemplary embodiment of the present invention, the re-judging whether a turbulence device is installed according to the operating frequency P of the motor during the pulping process may include:

[0064] Comparing the operating frequency P of the motor during the stirring process with the set power threshold P0;

[0065] When P≥P0, it is determined that the spoiler is installed; when P

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com