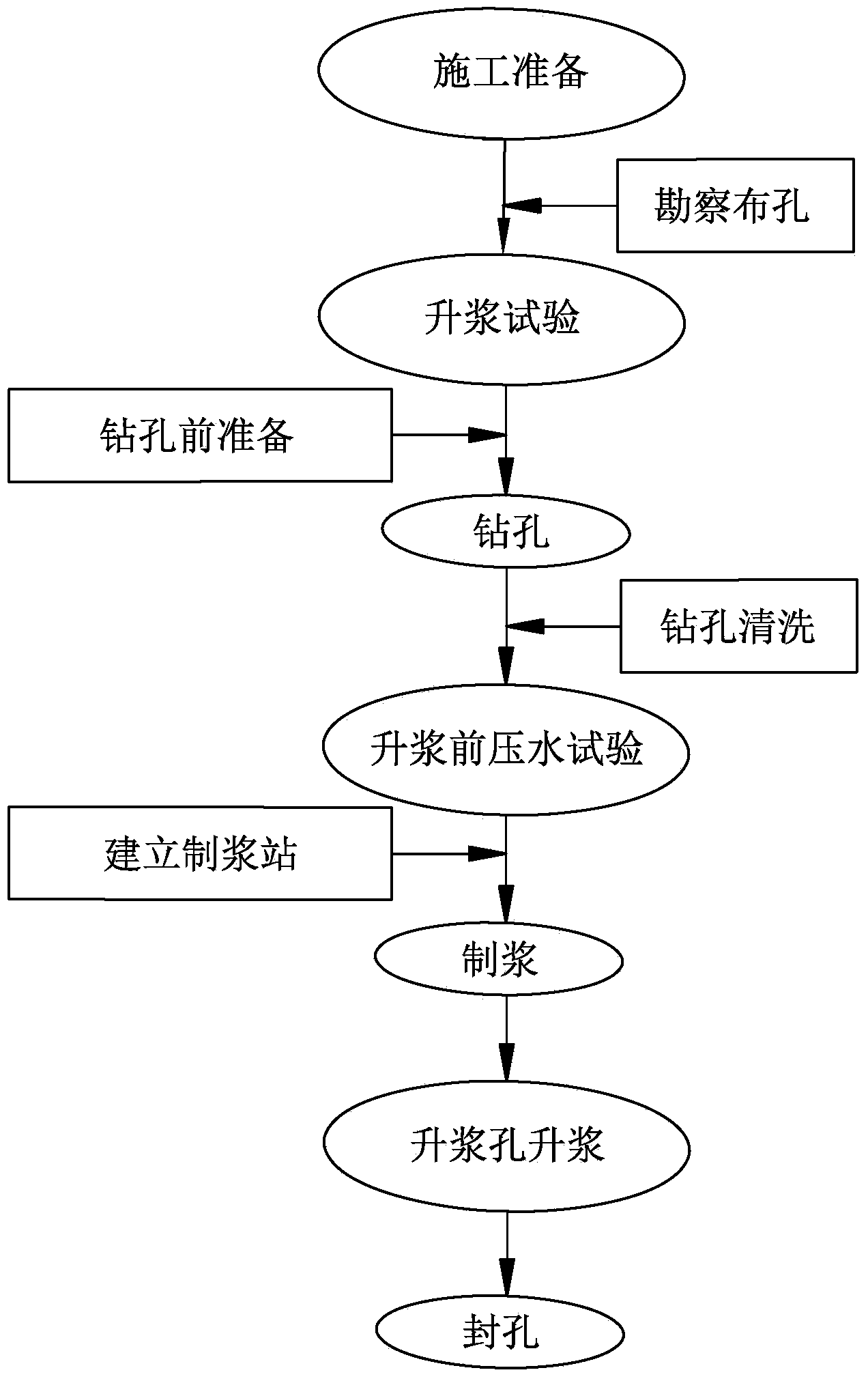

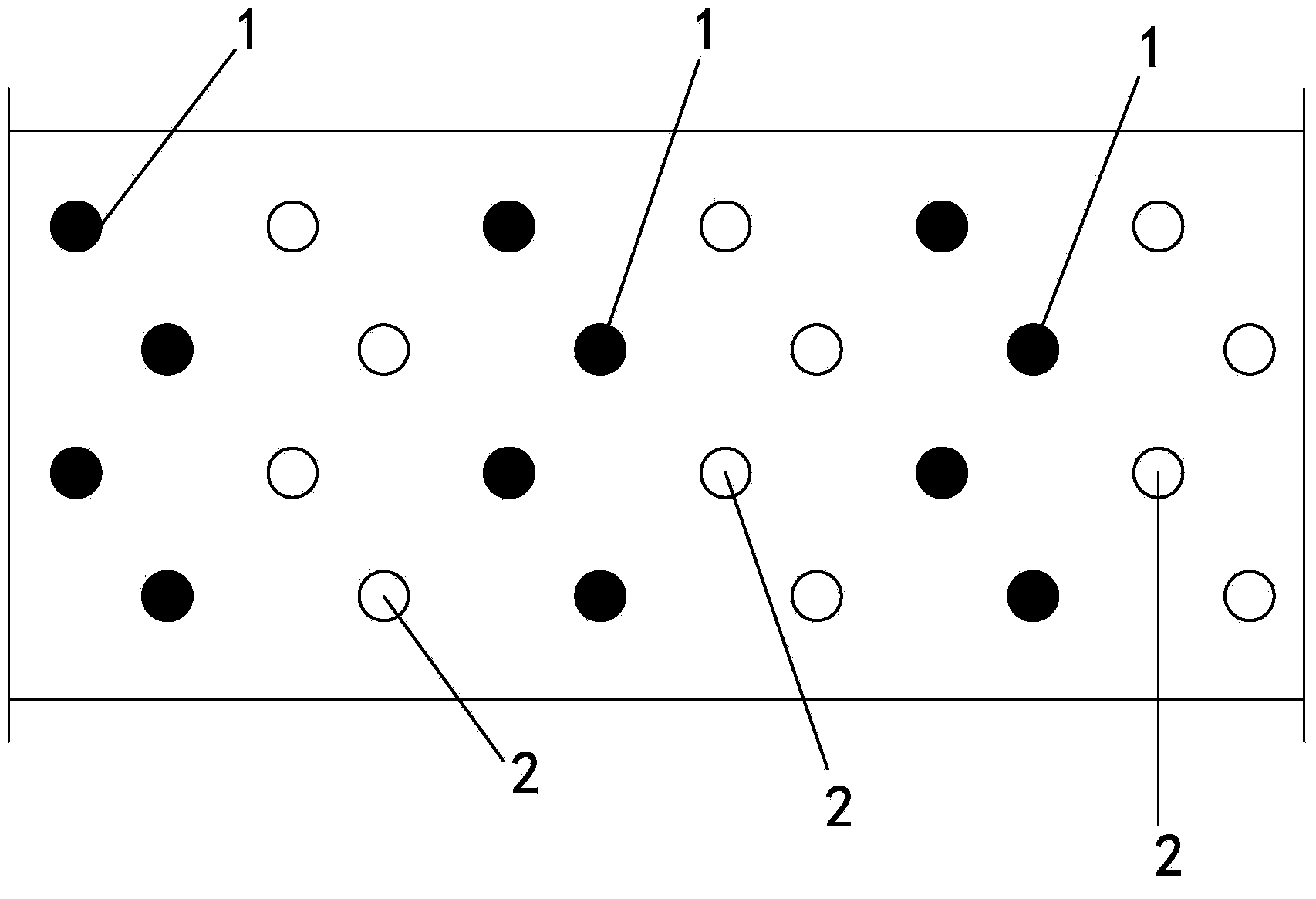

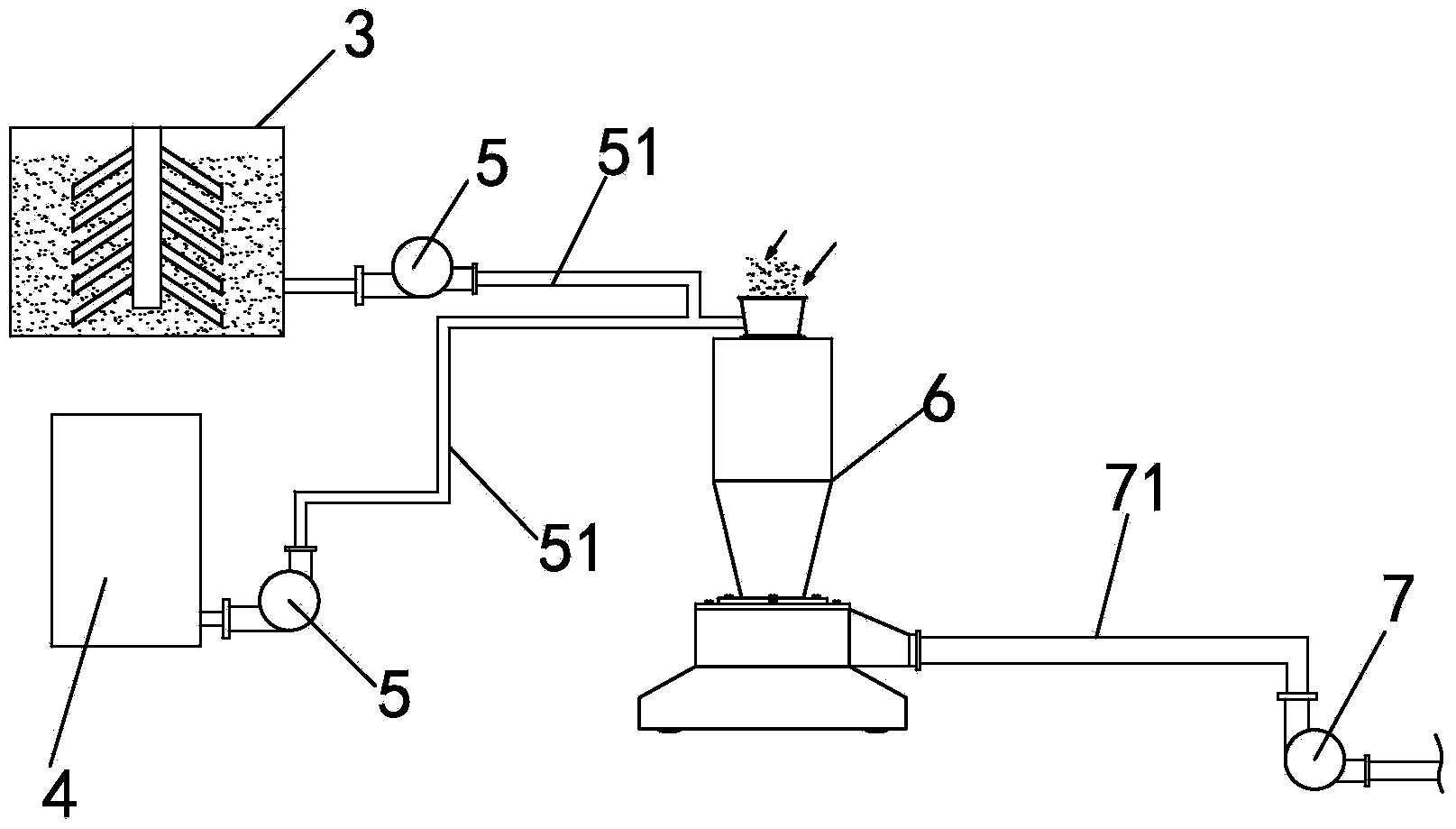

Drill hole prepacked aggregate concrete construction method

A construction method and concrete technology, applied in basic structure engineering, basic structure testing, construction, etc., can solve problems such as increasing construction difficulty, increasing construction cost, wasting manpower and material resources, and achieving shortened construction period, effective construction cost, and construction. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110]The parameters of the mass parts of each component of the slurry are selected as follows: 35 mass parts of water, 75 mass parts of cement, 60 mass parts of admixtures, and 10 mass parts of admixtures; after the above-mentioned test items are tested, the following data are obtained:

[0111]

[0112] The various indexes of embodiment 1 are all within the required indexes, meet the requirements of this construction method, and can be put into use.

Embodiment 2

[0114] The mass parts parameters of each component of the slurry are selected as follows: water mass parts are 35, cement mass parts are 80, admixtures are 65 mass parts, admixtures are 15 mass parts; after the above test items are tested, the following data are obtained:

[0115]

[0116] Part of the indicators in Example 2 are all within the required indicators. Due to the large amount of cement, the mixing time exceeds the required indicators, and the fluidity of the raised slurry also exceeds the required indicators, which does not meet the requirements of this construction method. It is necessary to adjust the components before it can be put into use. .

Embodiment 3

[0118] The parameters of the mass parts of each component of the slurry are selected as follows: 35 parts by mass of water, 70 parts by mass of cement, 65 parts by mass of admixtures, and 15 parts by mass of admixtures; after the above-mentioned test items, the following data are obtained:

[0119]

[0120] Part of the indicators in Example 3 are all within the required indicators. Due to the large amount of water, the density of the slurry is lower than the required indicators, and the strength of the slurry is also lower than the required indicators. It does not meet the requirements of this construction method. It is necessary to adjust the components before putting in use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com