Method for making baked pulp

A baking and slurry technology, applied in heating devices, cooking utensils, household utensils, etc., can solve the problems of uneven baking of materials and the inability of the motor-mounted model to stir the animal materials, so as to ensure the baking effect and improve the baking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

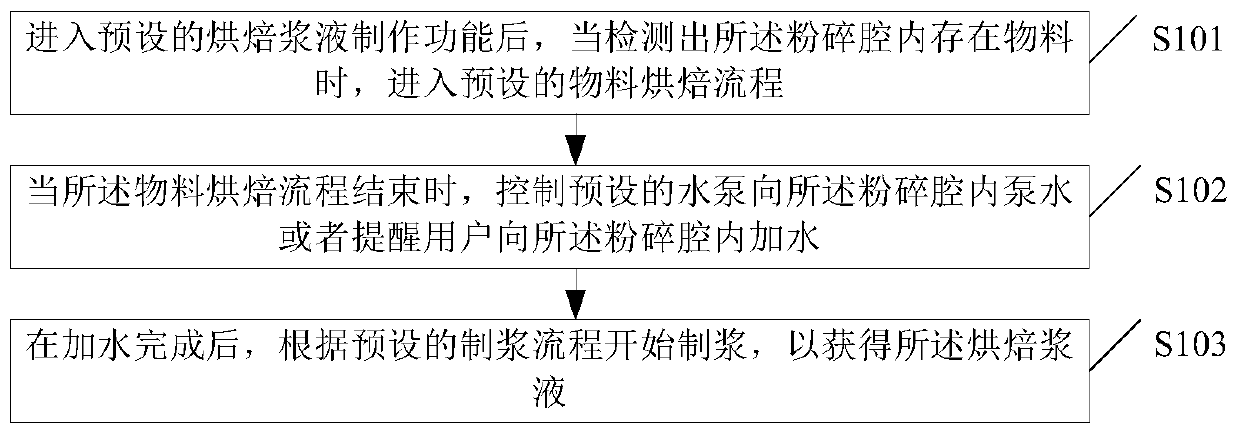

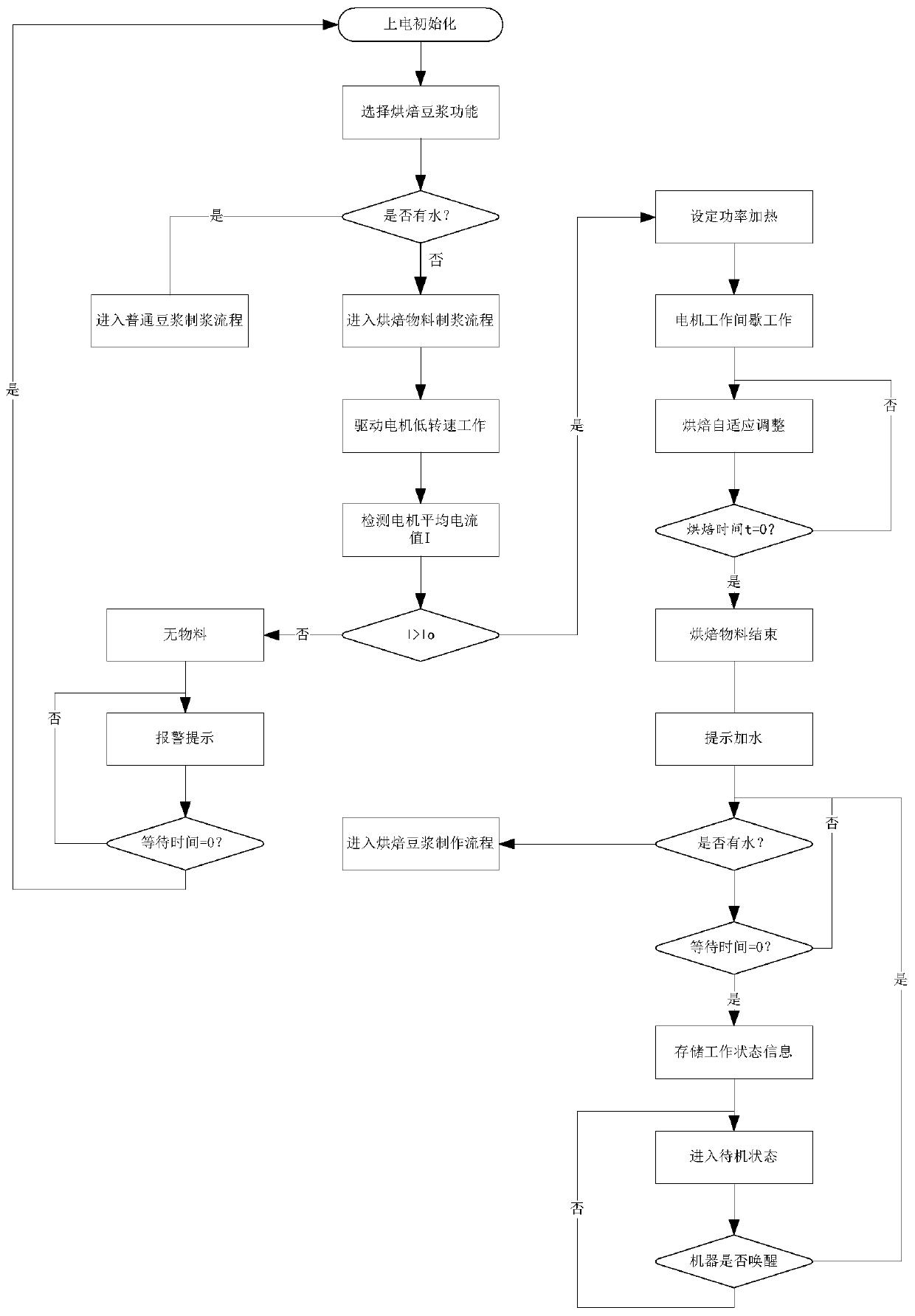

[0041] In order to achieve the above object, an embodiment of the present invention provides a pulping method for baking slurry, the food processor for making the baking slurry includes a motor, a grinding blade, a grinding chamber, a heating device and a temperature sensor; the temperature sensor is used for Real-time detection of the temperature of the heating device; the motor is located below the bottom of the crushing chamber, and the motor shaft of the motor penetrates into the crushing chamber, and the crushing blade is installed on the motor shaft, close to the bottom of the crushing chamber; as figure 1 , figure 2 As shown, the method may include S101-S103:

[0042] S101. After entering the preset baking slurry production function, when it is detected that there is material in the crushing chamber, enter the preset material baking process.

[0043] In an exemplary embodiment of the present invention, the method may further include: after entering the function of ba...

Embodiment 2

[0057] On the basis of the first embodiment, this embodiment provides a structural embodiment of a food processing machine with a motor under it.

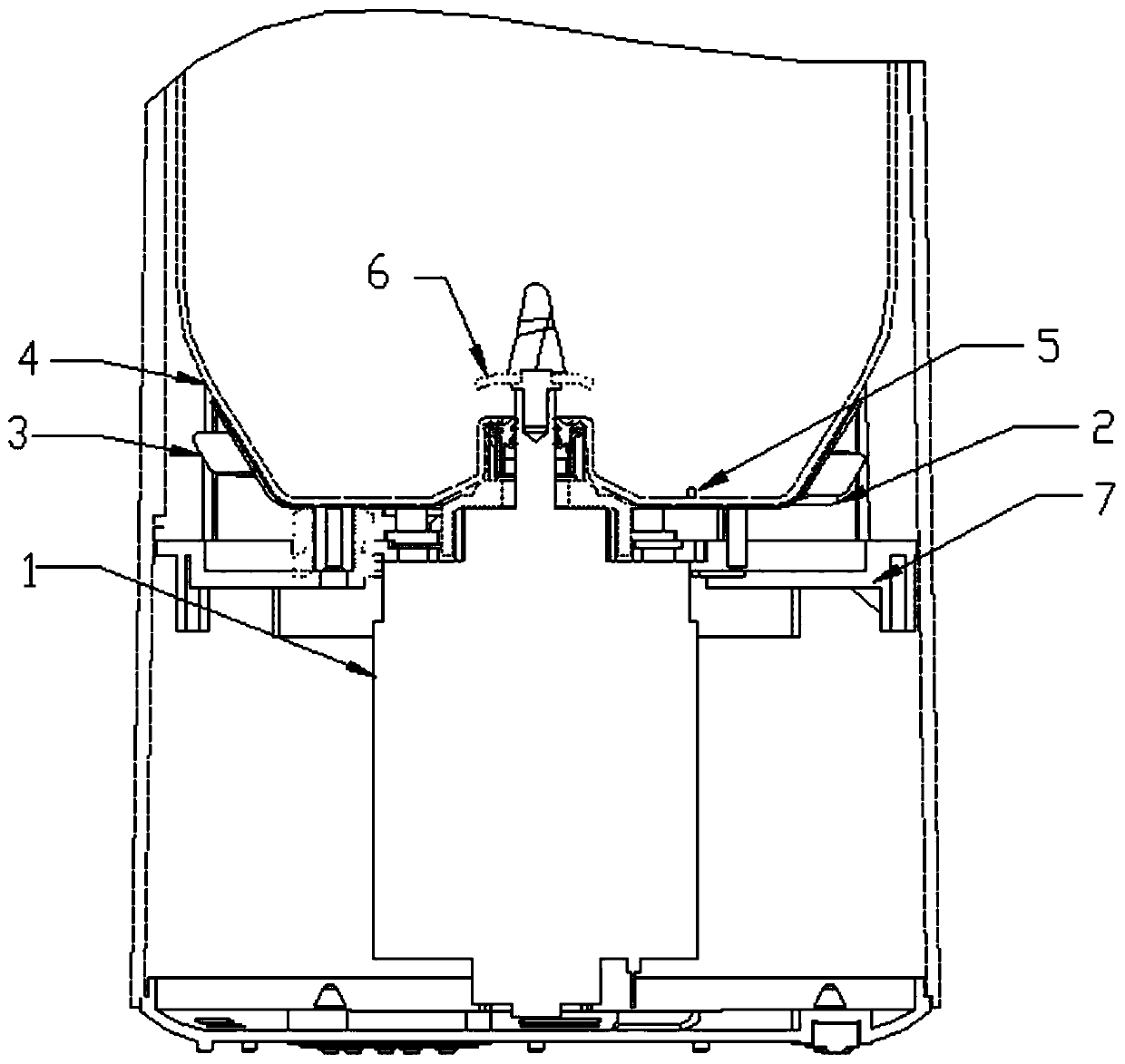

[0058] In an exemplary embodiment of the present invention, as image 3 As shown, the motor 1 of the under-motor food processing machine is fixed on the bottom of the heating cup body 4, the bracket 7 (circuit board bracket or motor fixing bracket) is opened to fix the motor 1, the crushing blade 6 is fixed on the motor 1, and the heating device 3 Placed on the side or bottom of the heating cup 4, the temperature sensor 2 is fixed on the heating device 3, and the inner bottom of the heating cup 4 is provided with a temperature sensor 5, the metal shell of the temperature sensor 5 is isolated from the heating cup 4 and reused for water detection .

[0059] In the exemplary embodiment of the present invention, by setting a temperature sensor on the heating device, the problem of uncontrolled temperature of the heating device and fre...

Embodiment 3

[0061] On the basis of any of the above-mentioned embodiments, this embodiment further limits the heating method when the material is baked.

[0062] In an exemplary embodiment of the present invention, the adjusting the heating mode and / or heating power of the heating device may include: controlling the heating device to perform the following operations in a cycle for a second preset duration:

[0063] After heating with the second preset power for a third preset duration, stop for a fourth preset duration.

[0064] In an exemplary embodiment of the present invention, the heating method of material baking can adopt the heating method of large and small fires, and the heating method of large and small fires can adopt the third preset duration of heating (such as 1 second) and then pause for a fourth preset duration (such as N seconds) , N is a positive number).

[0065] In an exemplary embodiment of the present invention, the system can adaptively adjust the stop time N secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com