Long slope vibratory slipform shaping mill

A molding machine and slope technology, which is applied in the field of long-slope vibrating sliding-form molding machines, can solve the problems of difficult maintenance and repair, complex structure and high cost in the later stage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

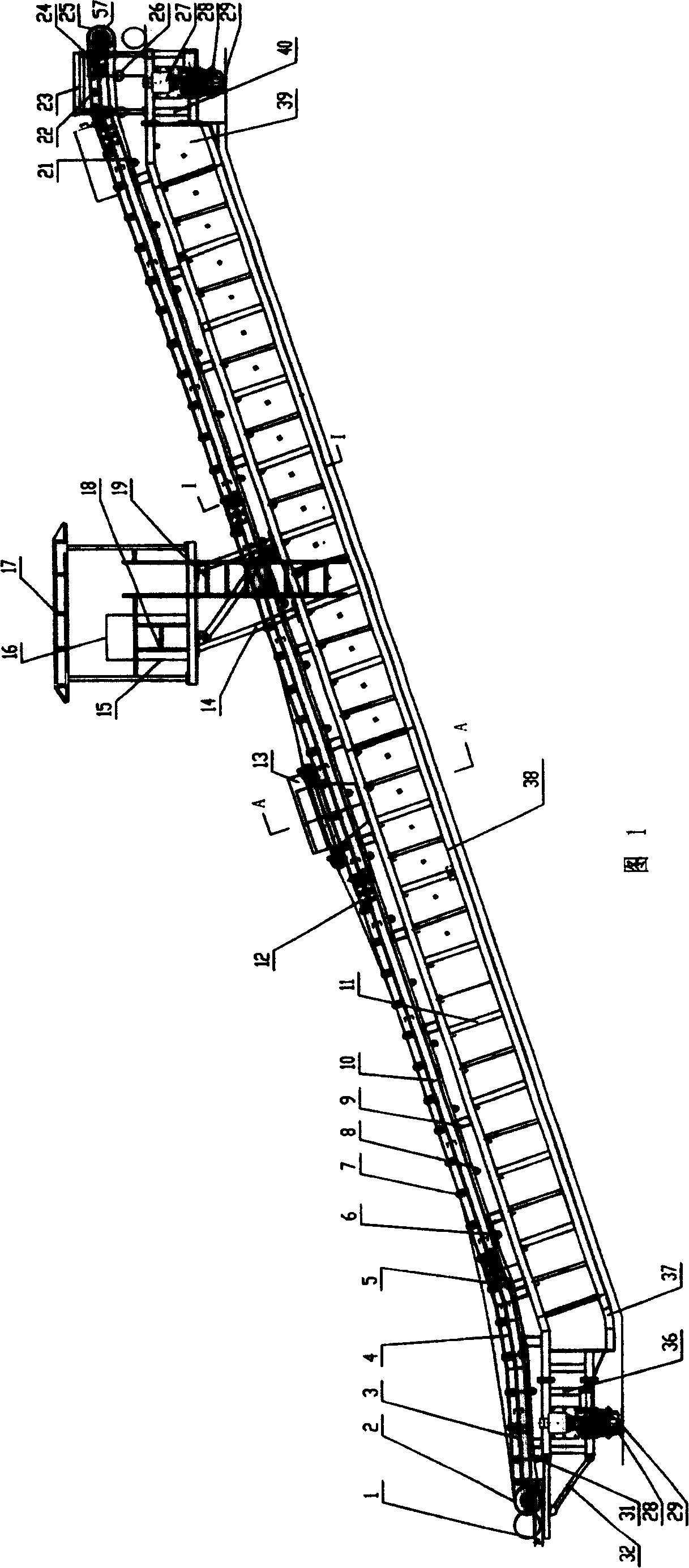

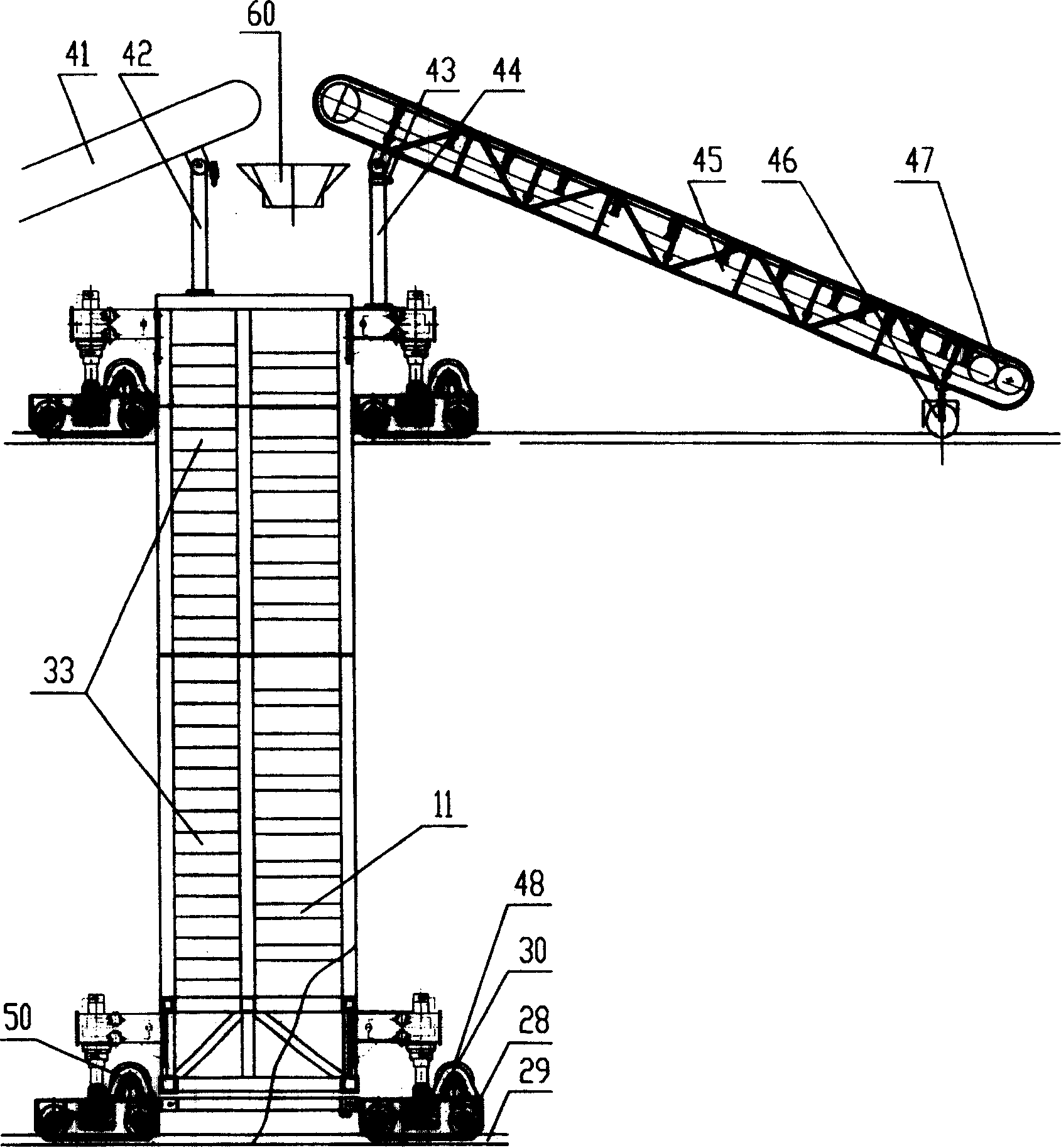

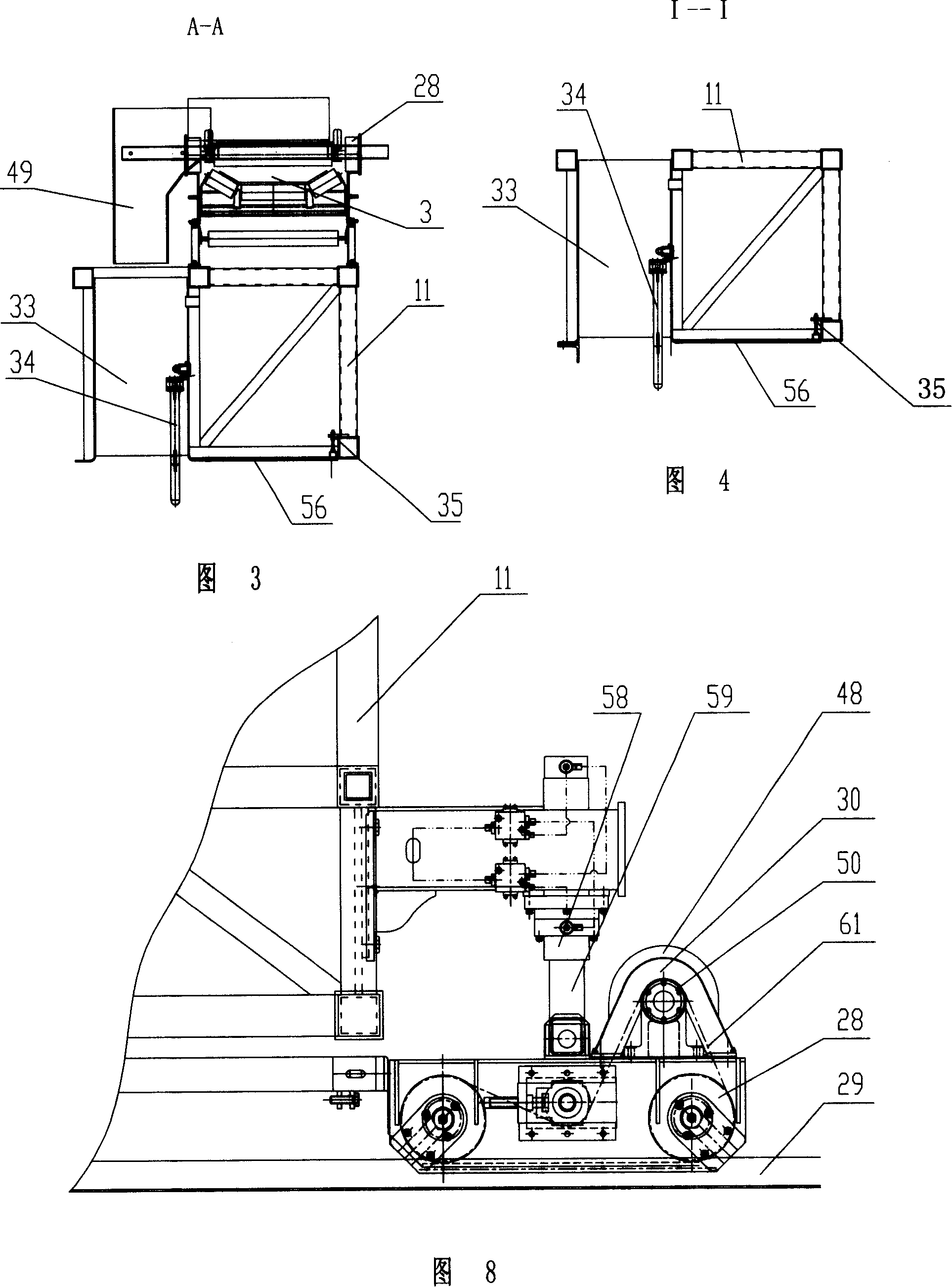

[0022] In order to clearly illustrate the technical characteristics of this solution, the following describes this solution through a specific implementation and in conjunction with the accompanying drawings.

[0023] The present invention is a long-slope vibration sliding mold forming machine, as shown in Figure 1, figure 2 , Figure 4, it includes a cloth device with a walking mechanism, the cloth device includes a frame 11 corresponding to the slope, a cloth conveyor belt 3 is installed on the frame 11, and a movable cloth trolley is set on the cloth conveyor belt 3 13. The distributing trolley 13 is connected to the hoist 57 through a wire rope, and has a control device for the hoist 57. The hoist can specifically adopt a frequency conversion, braking, cycloid or star gear reduction device, all rotating parts are arranged coaxially, and the assembly method is conventional technology . A silo 33 is provided on one side of the cloth conveyor belt 3, an electric vibrating rod 34 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com