Manufacture of smc insulation end cover for wind power generator

A technology for wind turbines and insulating ends, which is applied in the field of manufacturing SMC insulating end caps for wind turbines. It can solve the problems of low axial mechanical strength, damage to the insulating layer, and high radial mechanical strength, and achieve the effect of maintainability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

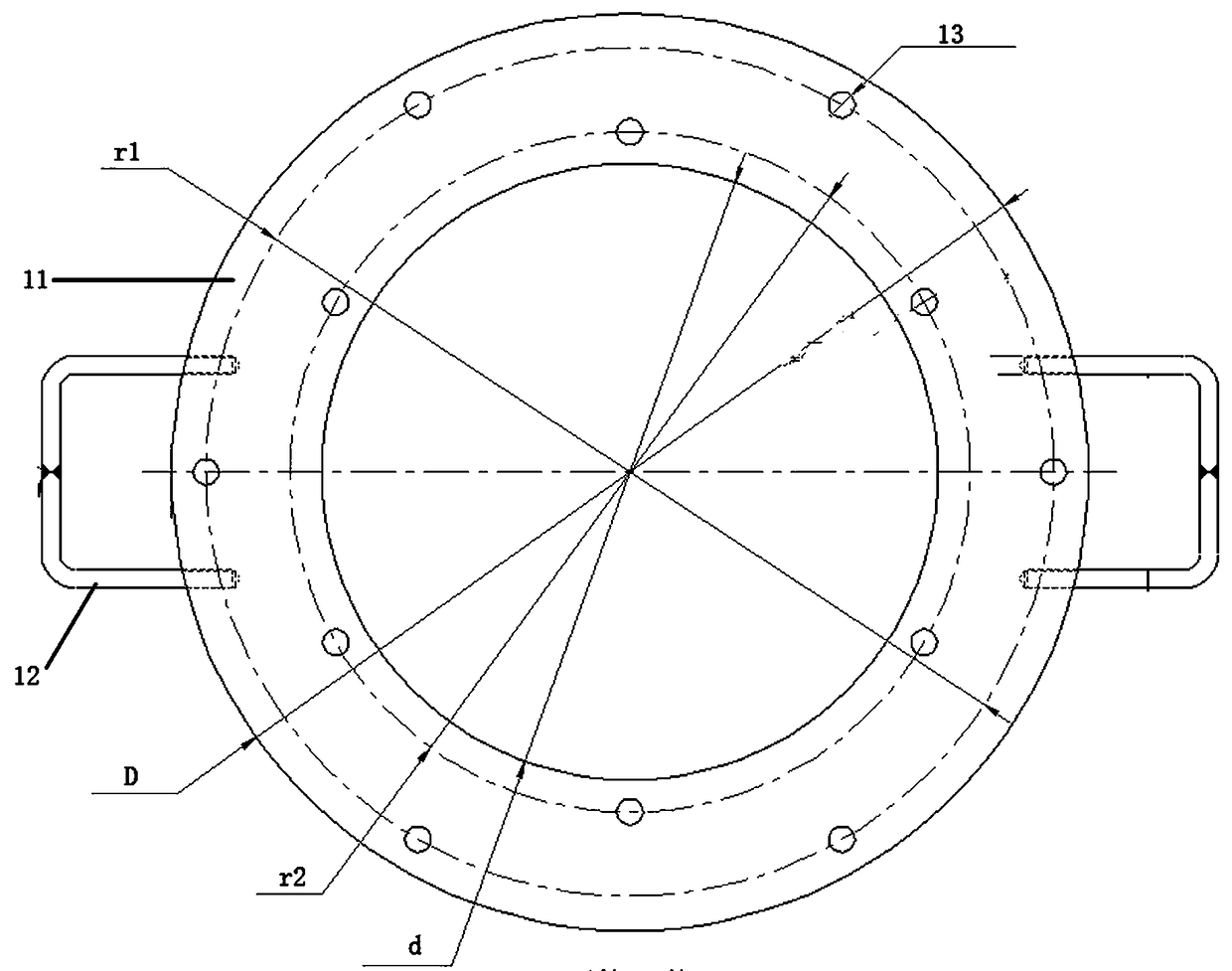

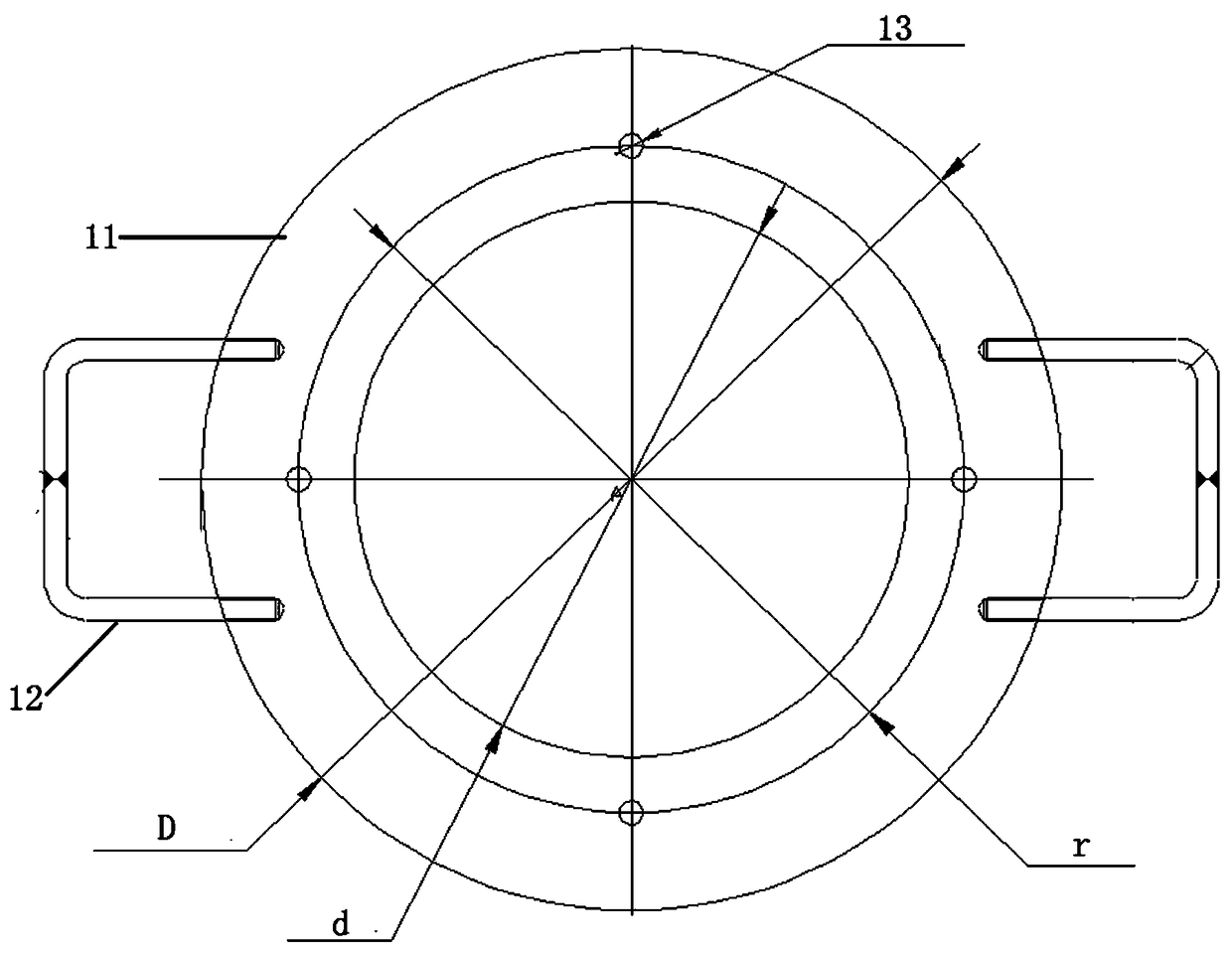

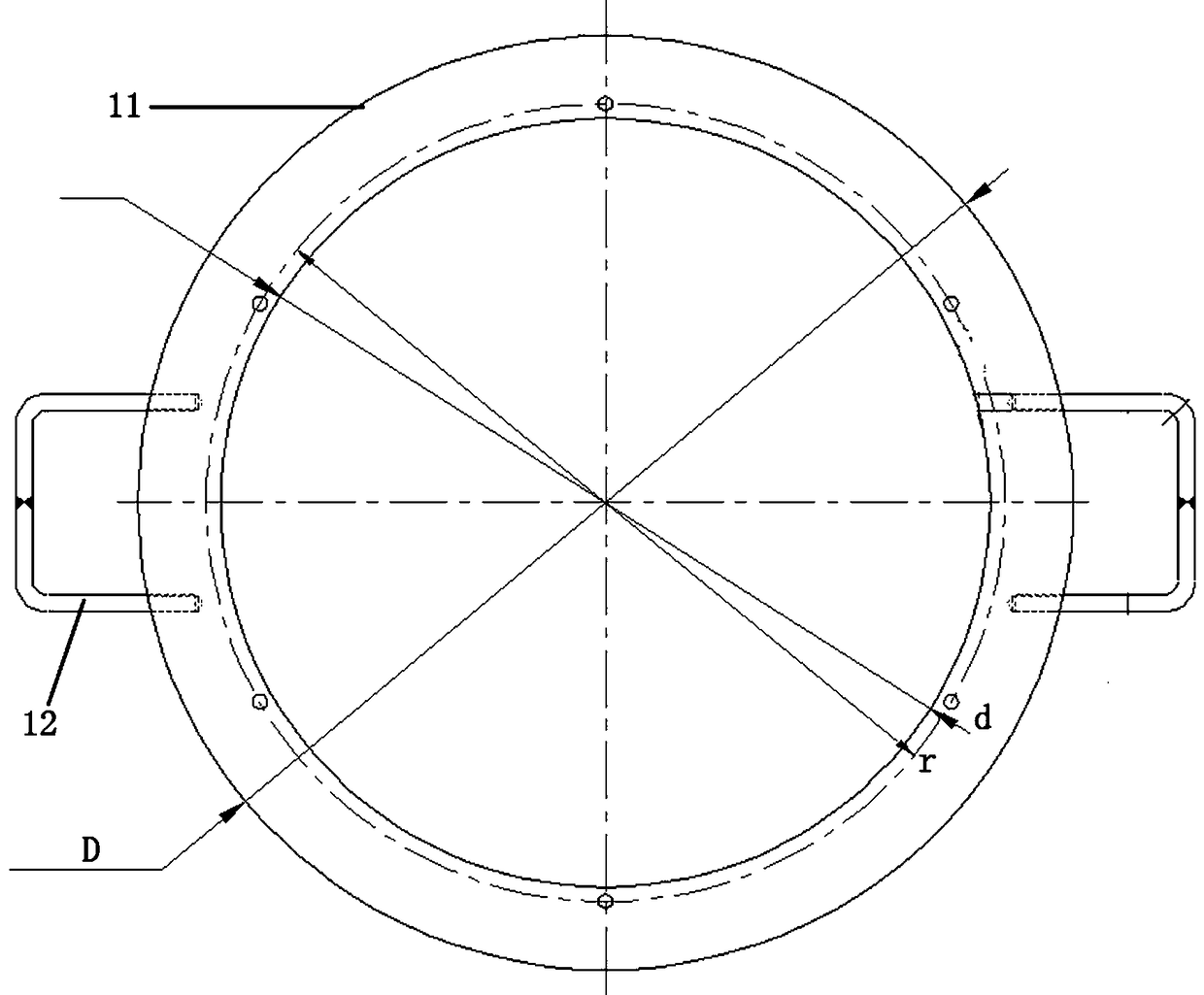

[0049]The crimping tooling includes a disc-shaped tooling main body 11 with a central hole; a pair of U-shaped handles 12 are symmetrically fixed on the outer side of the tooling main body 11 with the center of the tooling main body 11 as the center; the U-shaped The opening of the handle 12 is set towards the main body 11 of the tool; the plane where the pair of U-shaped handles 12 is located is parallel to the surface of the main body 11 of the tool; the main body 11 of the tool is provided with a plurality of pin holes 13 at equal intervals around its center.

[0050] The outer diameter D of the tooling main body 11 is 600mm, and the pin shaft holes 13 on the tooling main body 11 are two groups of inner and outer and both are six; the diameter r1 of the circle where the center of the outer pin shaft hole is located is 555mm; The diameter r2 of the circle is 445mm; the inner diameter d of the center hole of the tooling body 11 is 403mm; the arrangement of the outer pin hole a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com