Slope hydraulic self-propelled concealed-rail drag mold

A self-propelled, hydraulic technology, applied in the direction of coastline protection, etc., can solve the problems of unsatisfactory project quality and progress, unable to reduce construction unit cost, poor adaptability of slope length and slope ratio, etc., to save construction period and improve the surface quality of formwork Good, the effect of leveling the slope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

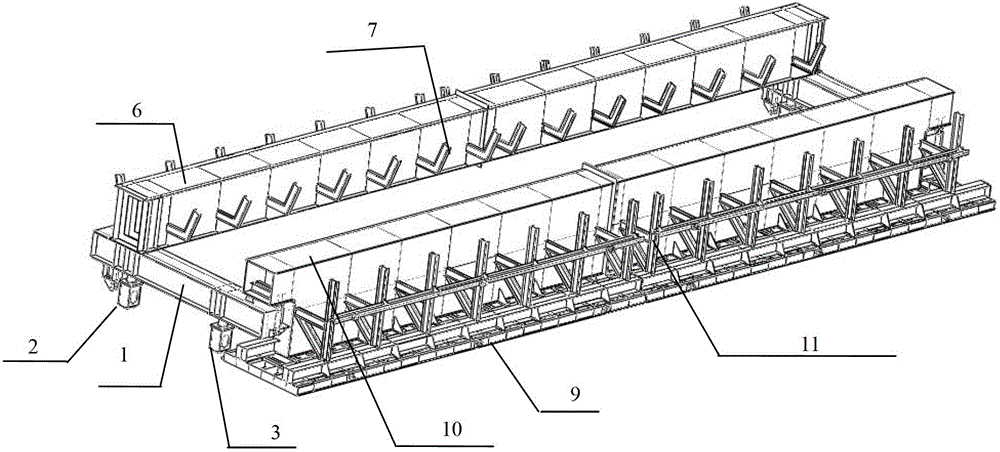

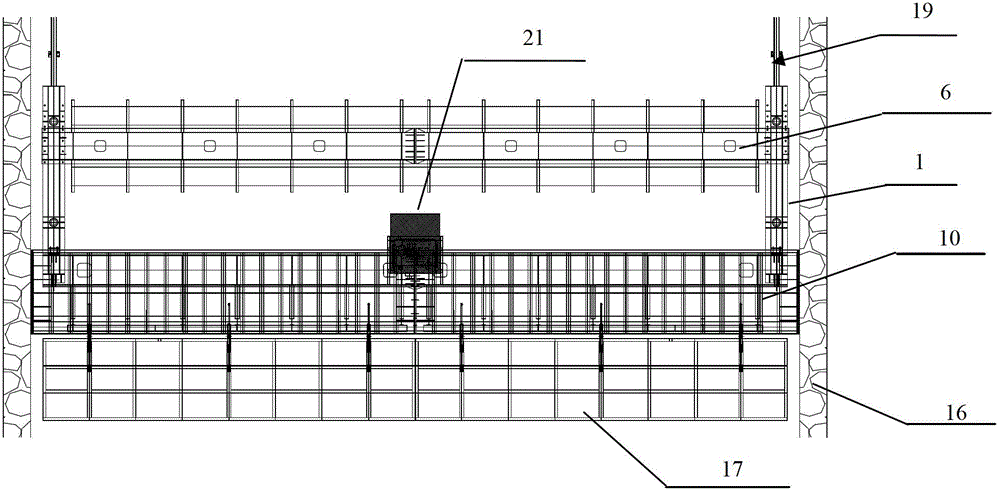

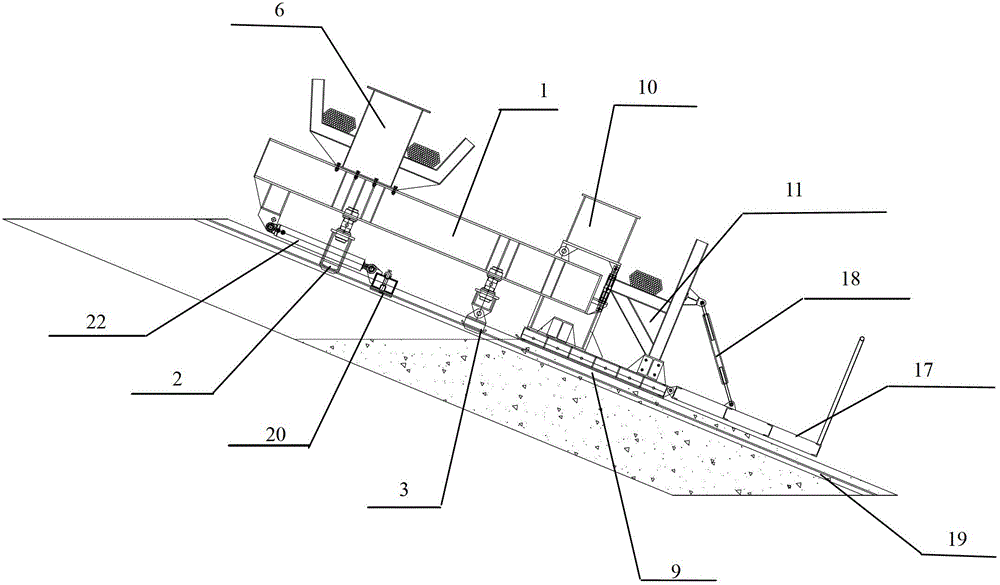

[0040] control Figure 1-Figure 19 , the present invention provides a kind of slope hydraulic self-propelled concealed rail dragging form, which is composed of a traveling beam, a balance beam 6, a formwork system, a working platform 17 and a hydraulic system; the traveling beam is a load-bearing beam 10 The fulcrums on both sides of the balance beam 6 are the running joists of the formwork system when the formwork is moved; Seat 2, rear sliding seat 3, adjusting screw 4, and oil cylinder seat 5 are set under the beam 1. According to the force characteristics and structural requirements, the front sliding seat 2 and the beam 1 are rigidly connected. The rail surface is an arc surface, and the rear slide Seat 3 and beam 1 are hinged, and the rail surface is flat to increase the contact area with the rail. This structure can meet the needs of different rail inclinations and height adjustment of the slide seat. An adjustment screw 4 is provided between the front slide 2, the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com