Material detecting method for food processor

A technology for food processing machines and material detection, which is used in volume measuring instruments/methods, engine lubrication, measuring capacity, etc. Processing effect, to achieve reasonable matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

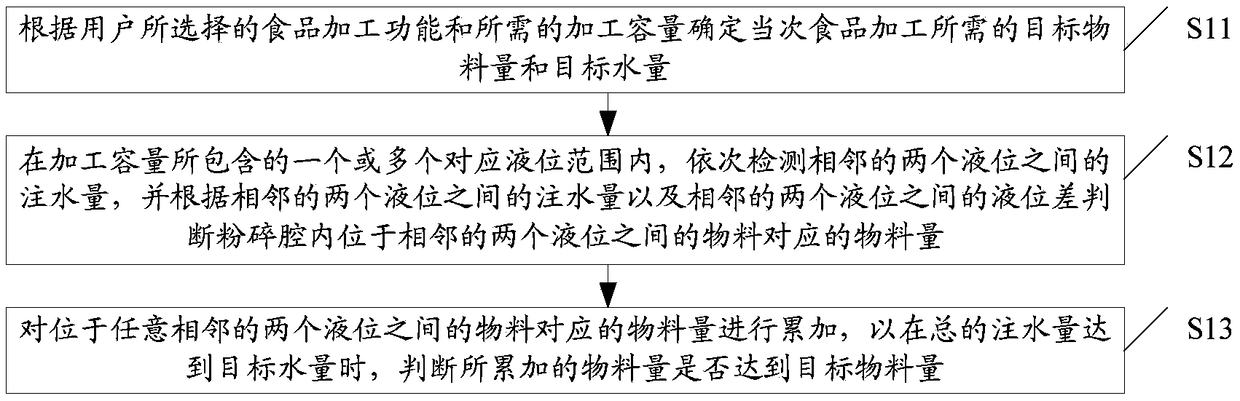

[0046]A material detection method for a food processing machine. The food processing machine may include: a water tank and a crushing chamber. The food processing machine may also include: a water inlet control device for controlling the amount of water injected by the water tank into the crushing chamber; There are multiple liquid level detection devices respectively used to detect different liquid levels; the food processing machine also includes an operation panel, and the operation panel is provided with selection keys for food processing functions and selection keys for processing capacity; figure 1 As shown, the method may include steps S11-S13:

[0047] S11. Determine the target amount of material and target water required for the current food processing according to the food processing function selected by the user and the required processing capacity;

[0048] S12. Within the range of one or more corresponding liquid levels included in the processing capacity, sequent...

Embodiment 2

[0066] This embodiment scheme further optimizes the food processing technology on the basis of embodiment one.

[0067] Optionally, the method may also include:

[0068] When water is injected to each liquid level, the material is stirred at a preset low speed so that the material is evenly spread on the bottom of the crushing chamber.

[0069] In the embodiment of the present invention, the materials may pile up when put in, so more liquid level detection devices are needed to detect them, and the liquid is circulated through the agitation of the motor, so that the materials can be evenly spread on the bottom of the crushing chamber , so as to judge the amount of material faster.

[0070] Optionally, the preset low rotational speed may include: 1500rpm-6000rpm.

[0071] In the embodiment of the present invention, the following embodiment plan can be used during specific implementation: start the slurry stirring program, keep the rotation speed between 1500rpm-6000rpm, stir ...

Embodiment 3

[0074] This embodiment plan further limits the processing technology of the food processor on the basis of any of the above embodiments.

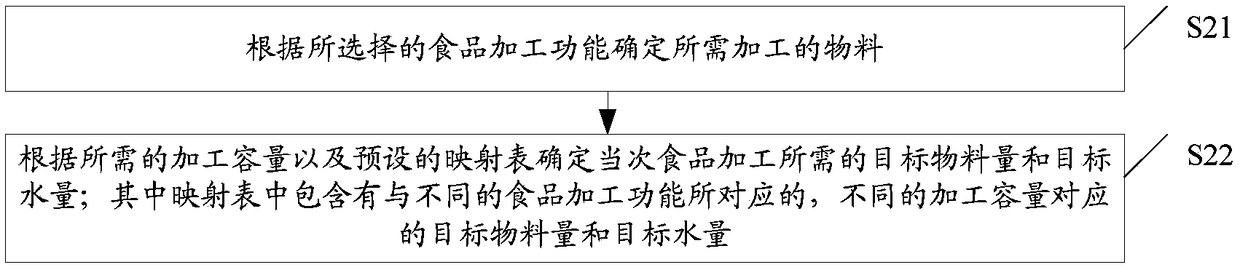

[0075] Optionally, food processing functions may include multiple types, and different food processing functions correspond to one or more food processing techniques.

[0076] In the embodiment of the present invention, different food processing functions may correspond to different food processing techniques, and the same food processing function may also correspond to different food processing techniques. For the same food processing function, when the processing capacity deviation is large, different processing techniques can be set for different processing capacities.

[0077]In the embodiment of the present invention, ordinary food processing machines usually only have function selection, no processing capacity selection, and after entering the food processing function, no matter how much material is added and the water level is high o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com