Soybean milk making method of soybean milk making machine with ordering function

A soymilk machine and pulping technology, applied in dairy products, beverage preparation devices, milk substitutes, etc., can solve the problems of complex operation and high noise, and achieve good pulping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

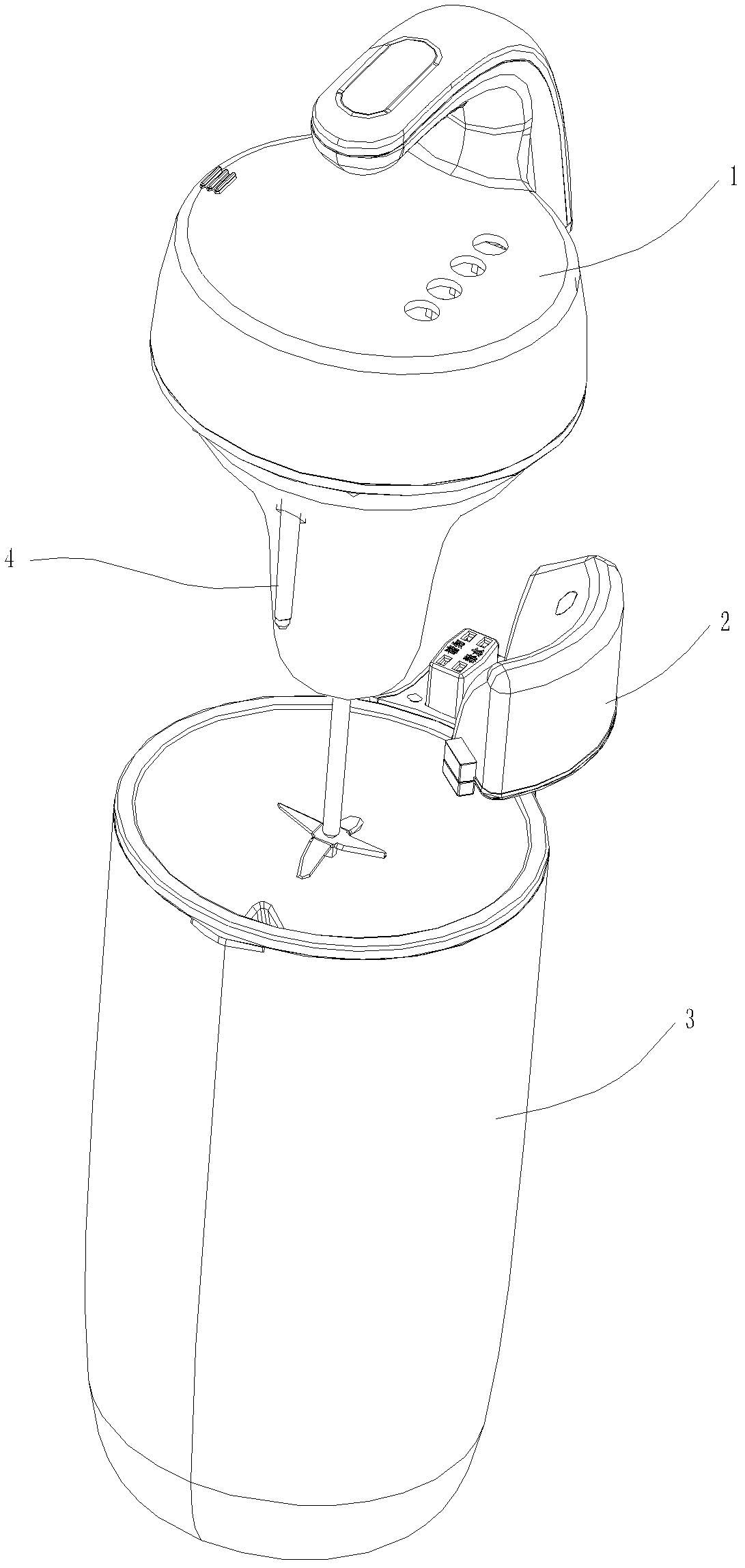

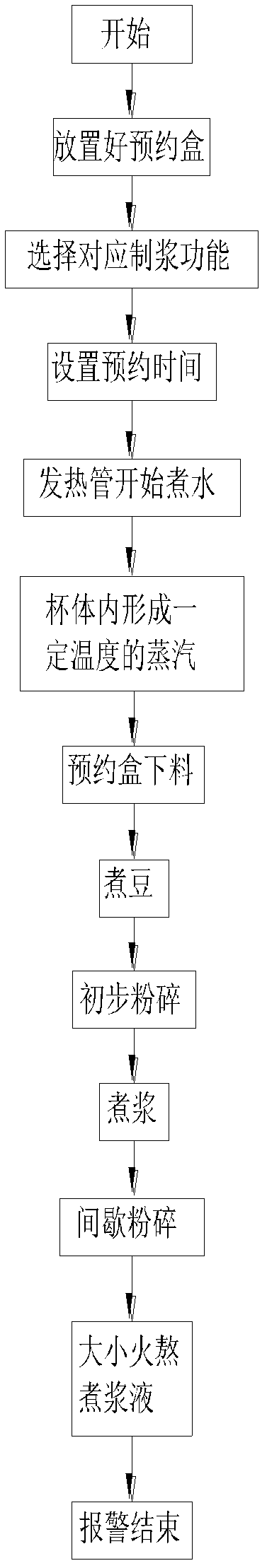

[0030] refer to Figure 1-3 , a pulping method of a soybean milk machine with reservation function, the steps are as follows:

[0031] (1) The pulping process starts;

[0032] (2) Place the appointment box;

[0033] (3) Select the corresponding pulping function;

[0034] (4) Set the appointment time;

[0035] (5) When the appointment time is up, the heating tube of the soybean milk machine starts to boil water;

[0036] (6) Steam at a certain temperature is formed in the cup of the soybean milk machine, and the reservation box is opened for feeding;

[0037] (7) The soymilk machine enters the bean cooking program;

[0038] (8) The motor of the soya-bean milk machine is started, and the cutter initially pulverizes the material;

[0039] (9) Soymilk machine enters the cooking process;

[0040] (10) The motor of the soymilk machine operates intermittently, and the knives intermittently crush materials;

[0041] (11) The soya-bean milk machine enters the high and low heat ...

Embodiment 2

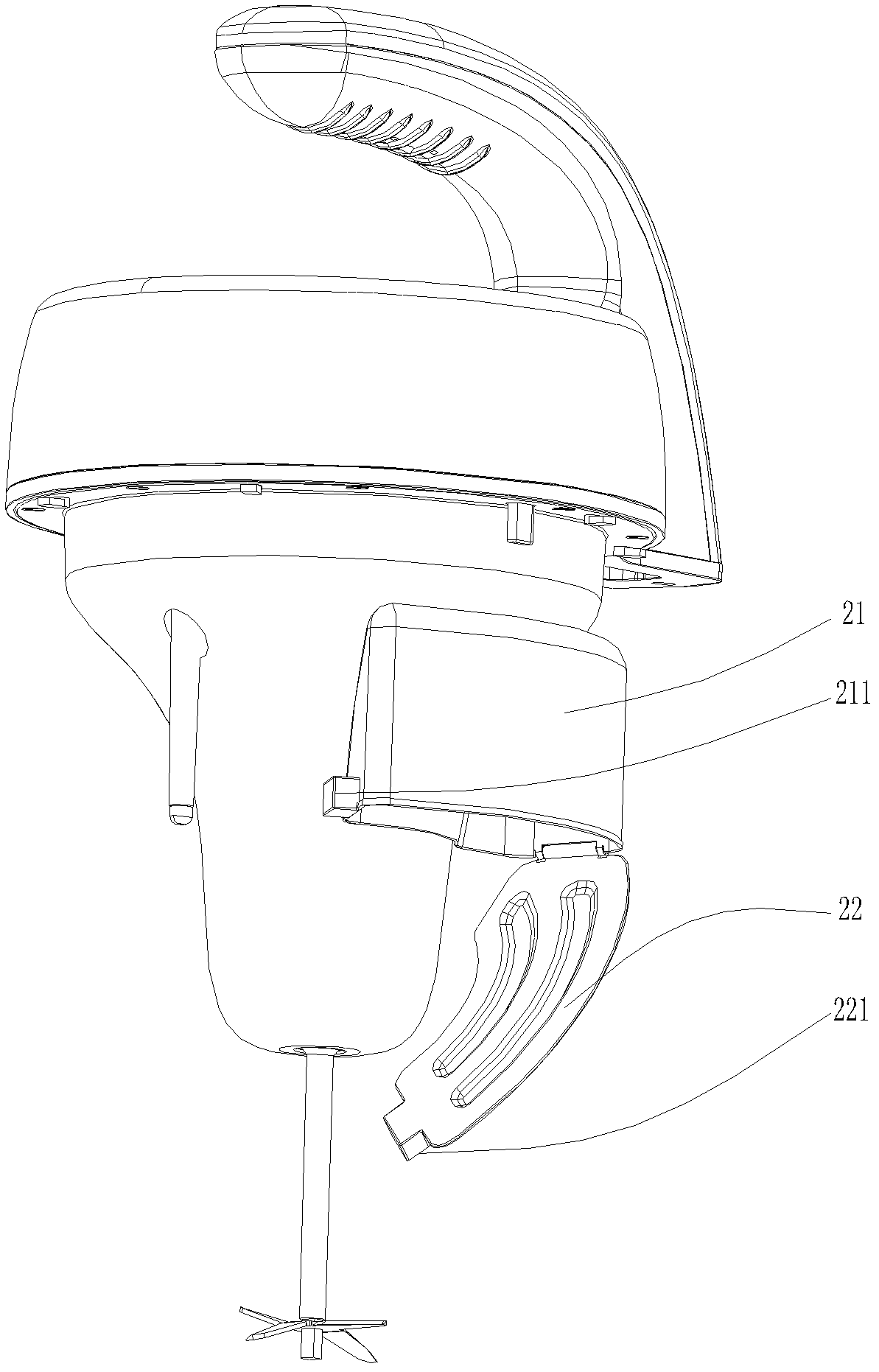

[0047] refer to Figure 4 , Figure 5 The difference between this embodiment and the first embodiment is that a detection step is added between step (9) and step (10). The detection step is to detect whether the liquid surface touches the anti-overflow electrode 4 of the soybean milk machine. If the soymilk machine detects that the liquid level does not touch the anti-overflow electrode 4, it enters step (5); when the soymilk machine detects that the liquid level touches the anti-overflow electrode 4, the soymilk machine performs the intermittent cooking procedure, and then enters step (10).

[0048] The setting time of the pulp cooking program in step (9) is greater than 1.2 times of the maximum time that the slurry can touch the anti-overflow electrode. This ensures sufficient time for the slurry to hit the anti-spill electrode.

[0049] Adding a self-test program can ensure that the materials in the reservation box are successfully unloaded. When the set time of the cook...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com