Soybean milk machine capable of automatically selecting pulping program according to water level

An automatic selection, soymilk machine technology, applied in dairy products, food preparation, beverage preparation devices, etc., can solve the problems of unsatisfactory pulping effect, and the pulping procedure cannot be changed automatically, and achieves simple structure and good pulping effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

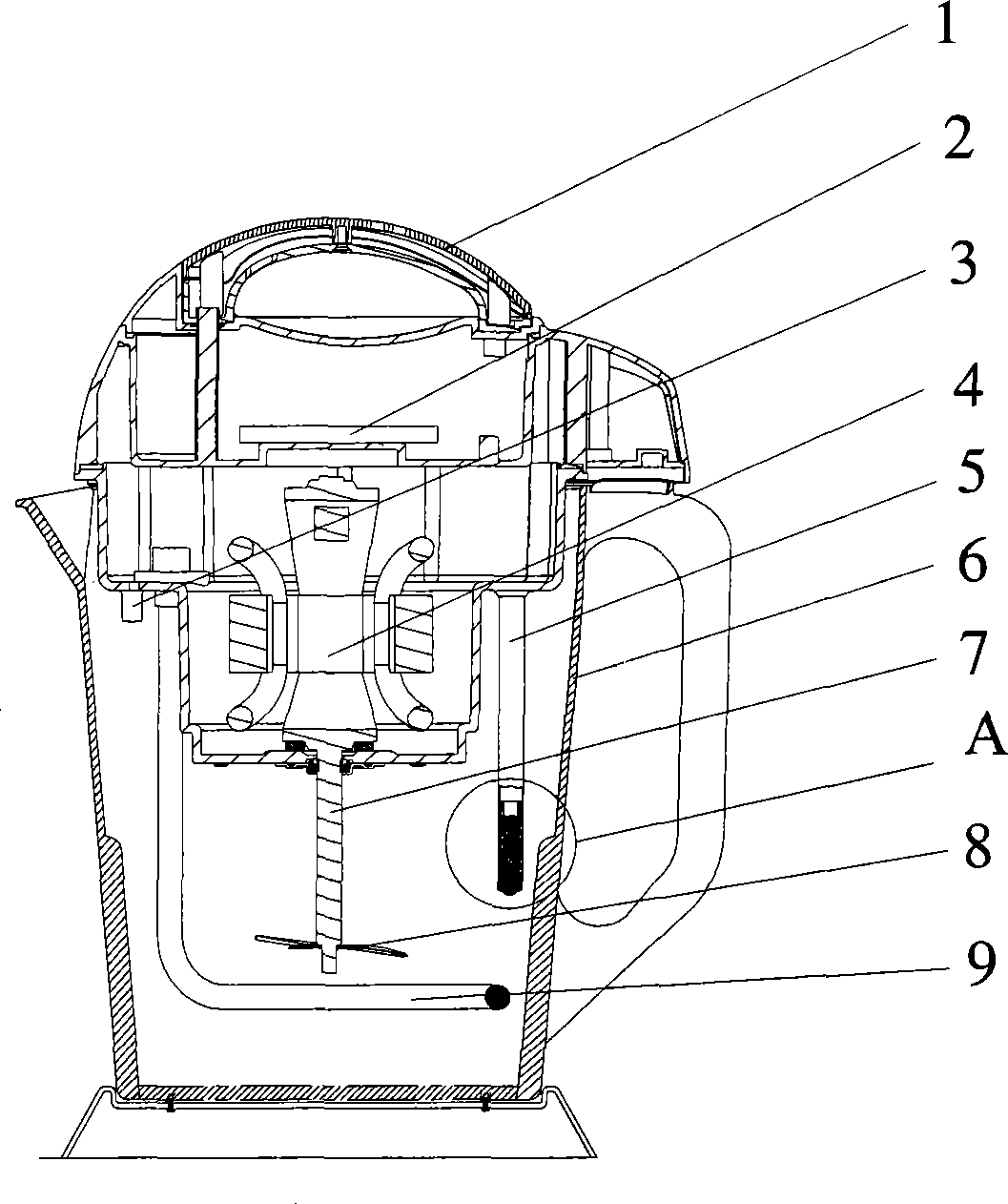

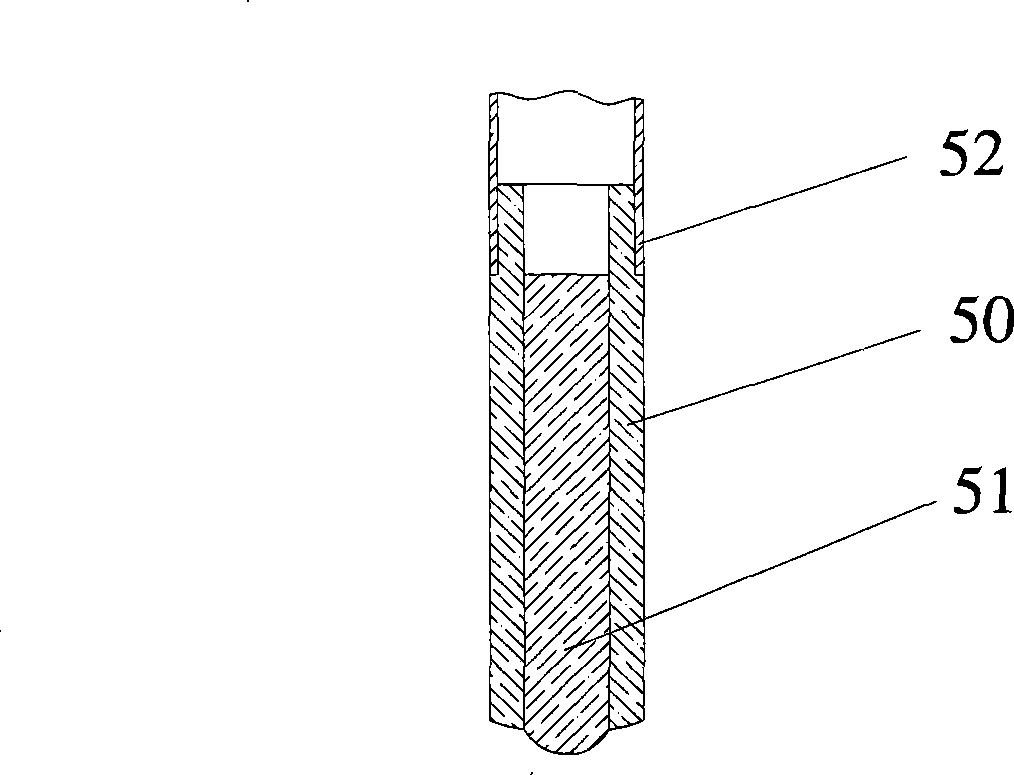

[0023] Such as figure 1 As shown, the present invention includes a machine head 1 and a pulping container 6, the machine head 1 is fastened on the pulping container 6, wherein the machine head 1 is provided with a control circuit 2, a motor 4, a heating device 9, an overflow prevention device 3, The rotating shaft 7 of the crushing device connecting the motor 4 and the crushing device 8, the water level detection device is electrically connected to the control circuit 2, and the control circuit 2 pre-stores different pulping procedures for beating according to the detection results of the water level detection points, that is, the water level is different. , the corresponding pulping procedures are also different. The different pulping procedures are mainly the number of times of beating, the time of each beating and the time interval between two adjacent beatings, the heating times of the heating device 9, the time of each heating, etc. Different; the water level detection de...

Embodiment 2

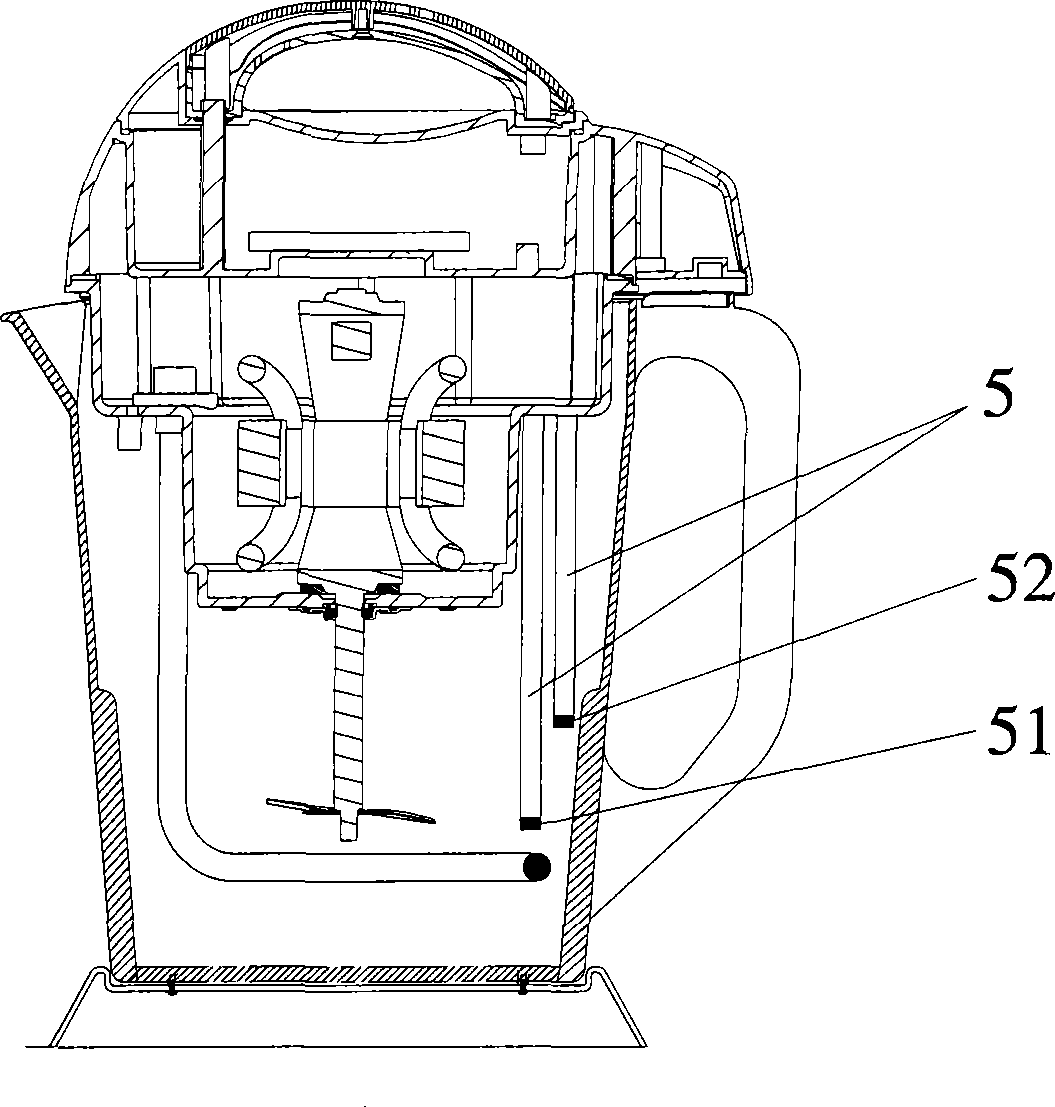

[0026] Such as image 3 As shown, this embodiment is generally the same as Embodiment 1, the difference is that the water level detection device 5 in this embodiment is two water level probes of different lengths installed on the machine head 1, and two water level detection points 51 and 52 are respectively located on different water level probes, forming detection points with different heights and low positions.

Embodiment 3

[0028] Such as Figure 4 As shown, this embodiment is generally the same as Embodiment 1, except that the water level detection device in this embodiment is the rotating shaft 7 of the crushing device, and the water level detection points 51, 52 are located at different positions on the rotating shaft 7 of the crushing device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com