Oxygen alkaline pulping cooking device

A kind of cooking equipment and pulping technology, which is applied in the direction of pulping with inorganic alkali, etc., can solve the problem that grass plant fiber cannot be effectively used, black liquor extraction and black liquor evaporation efficiency are reduced, black liquor recovery cannot be effectively solved, etc. problem, to achieve the effect of reducing scaling, easy to bleach, and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

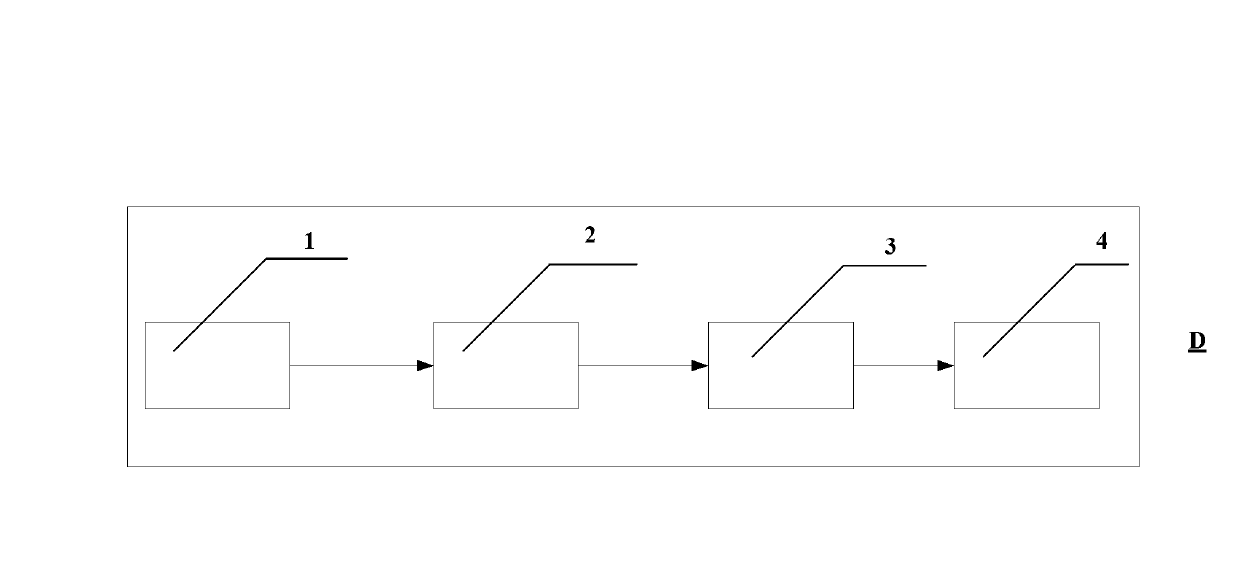

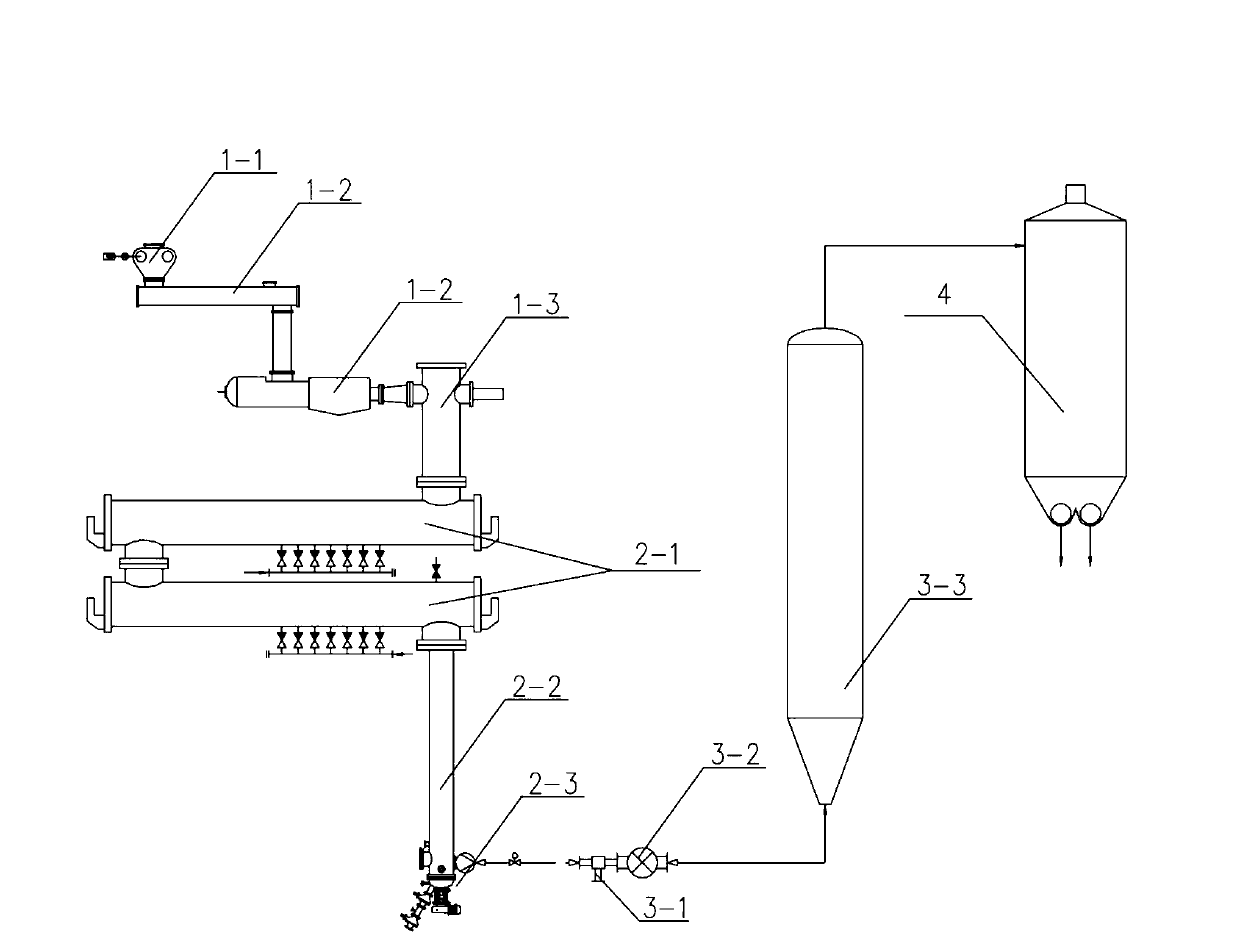

[0048] according to figure 1 The shown oxygen-alkali pulping cooking equipment D according to an embodiment of the present invention includes: a feeding device 1, a pre-cooking device 2, a cooking device 3 and a material spraying device 4, wherein the feeding device 1 and the pre-cooking device The first end of the device 2 is connected, and is used to transport the pulping raw material to the pre-cooking device 2 for pre-cooking; the second end of the pre-cooking device 2 is connected to the first end of the cooking device 3, and is used for pre-cooking The finished pulping raw materials are transported to the cooking device 3 for cooking; the second end of the cooking device 3 is connected to the material spraying device 4 for transporting the cooked slurry to the material spraying device 4 for spraying. according to figure 2 The shown oxygen-alkali pulping and cooking equipment D for grass slices according to an embodiment of the present invention, wherein the feeding dev...

Embodiment 2

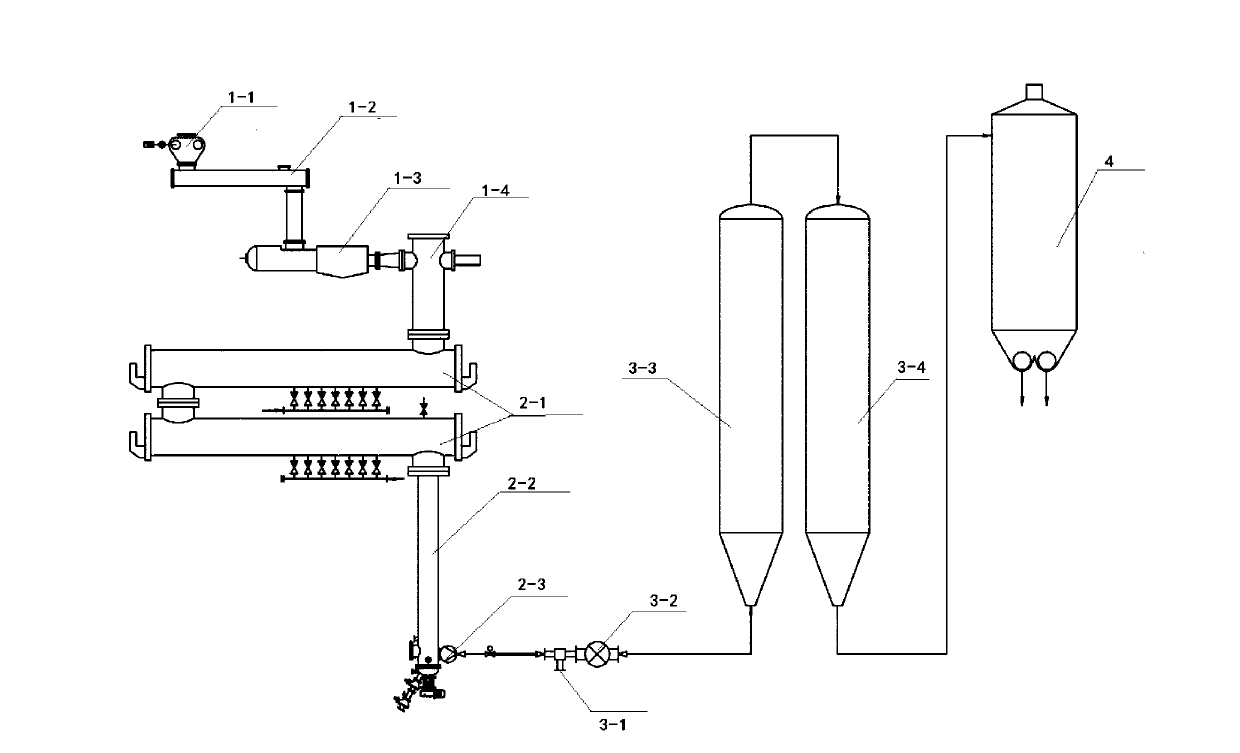

[0052] according to figure 1 The shown oxygen-alkali pulping cooking equipment D according to an embodiment of the present invention includes: a feeding device 1, a pre-cooking device 2, a cooking device 3 and a material spraying device 4, wherein the feeding device 1 and the pre-cooking device The first end of the device 2 is connected, and is used to transport the pulping raw material to the pre-cooking device 2 for pre-cooking; the second end of the pre-cooking device 2 is connected to the first end of the cooking device 3, and is used for pre-cooking The finished pulping raw materials are transported to the cooking device 3 for cooking; the second end of the cooking device 3 is connected to the material spraying device 4 for transporting the cooked slurry to the material spraying device 4 for spraying. according to image 3 The shown oxygen-alkali pulping and cooking equipment for grass slices according to an embodiment of the present invention, wherein the feeding device...

Embodiment 3

[0056] according to figure 1 The shown oxygen-alkali pulping cooking equipment D according to an embodiment of the present invention includes: a feeding device 1, a pre-cooking device 2, a cooking device 3 and a material spraying device 4, wherein the feeding device 1 and the pre-cooking device The first end of the device 2 is connected, and is used to transport the pulping raw material to the pre-cooking device 2 for pre-cooking; the second end of the pre-cooking device 2 is connected to the first end of the cooking device 3, and is used for pre-cooking The finished pulping raw materials are transported to the cooking device 3 for cooking; the second end of the cooking device 3 is connected to the material spraying device 4 for transporting the cooked slurry to the material spraying device 4 for spraying. according to Figure 4 The shown wood chip oxygen-alkali pulping and cooking equipment D according to an embodiment of the present invention, wherein the feeding device 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com