Anti-overflow control method of soybean milk machine

A control method and technology for a soymilk machine, which are applied in beverage preparation devices, household appliances, applications, etc., can solve problems such as affecting the portability of users, reducing the effective utilization rate of the cup body, and incapable of fully mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

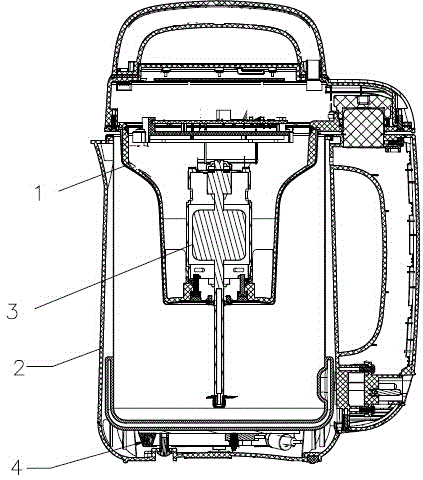

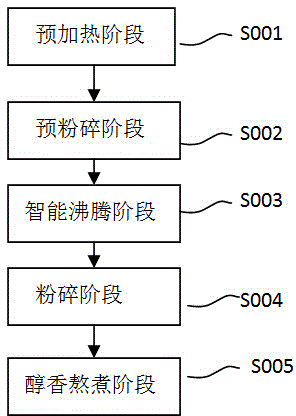

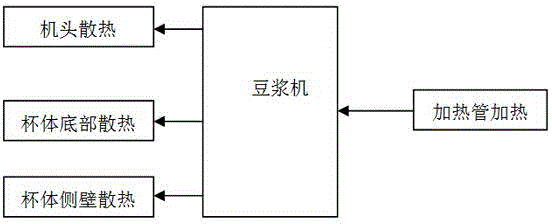

[0023] An overflow control method for a soymilk maker of the present invention, the soymilk maker includes a cup body, a motor for pulverizing and stirring materials in the cup body, a heating device for heating the slurry in the cup body, and a cup for detecting The temperature sensor of the slurry temperature in the body, the temperature sensor, the heating device and the motor are respectively electrically connected to the main control chip, wherein the overflow temperature T is preset in the main control chip, and the main control chip detects the temperature and the overflow temperature according to the temperature sensor. The temperature T adjusts the working state and real-time working power of the motor and heating device. When the main control chip detects that the temperature of the slurry reaches the overflow temperature, the main control chip controls the heating device to stop heating and controls the motor to stir the slurry. Therefore, through the fine control of...

Embodiment 2

[0040] The difference between this embodiment and the above-mentioned embodiment 1 is that, during the boiling stage and the boiling stage, the motor works during the operation of the heating device.

[0041] The main factor leading to the generation of slurry foam in the cup is that after the slurry reaches the overflow temperature, although the heating device stops heating, due to the influence of the residual heat of the heating device, the residual heat of the heating device accumulates inside the slurry at this time, causing the slurry to be in a boiling state. When the slurry boils, A large amount of water vapor generated by the boiling of water is mixed into the slurry to cause foaming. Therefore, during the boiling stage and the boiling stage, when the heating device is working, the motor works. When the motor is working, its rotational speed is N, where 500r / min≤N≤1500r / min.

[0042] It is known that the density of water is ρ, the density of water vapor is ρ1, the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com