Solar cell piece group and preparation method thereof

A technology of solar cells and cells, which is applied in the field of solar cells and can solve problems such as infirmity and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

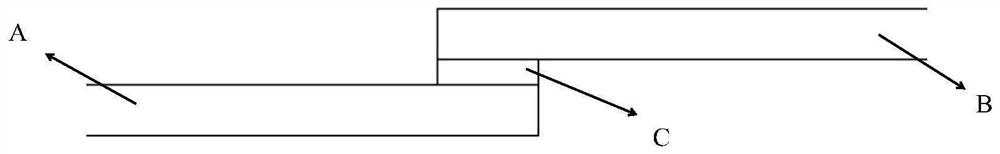

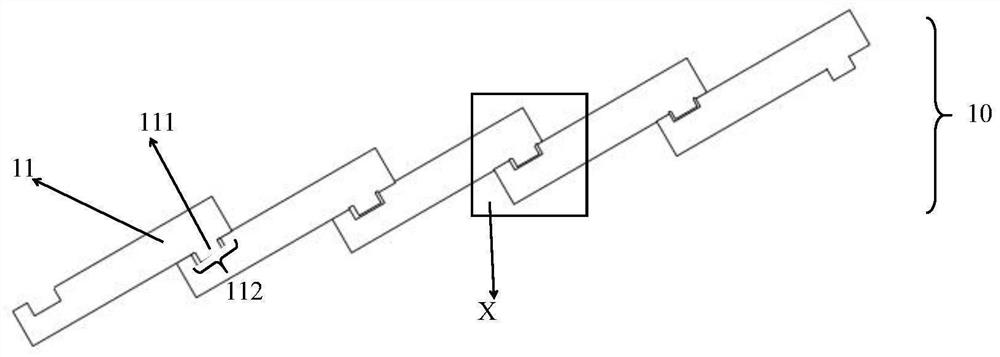

[0073] refer to figure 2 , shows a solar battery sheet group 10, the solar battery sheet group includes: including at least two solar battery sheets 11;

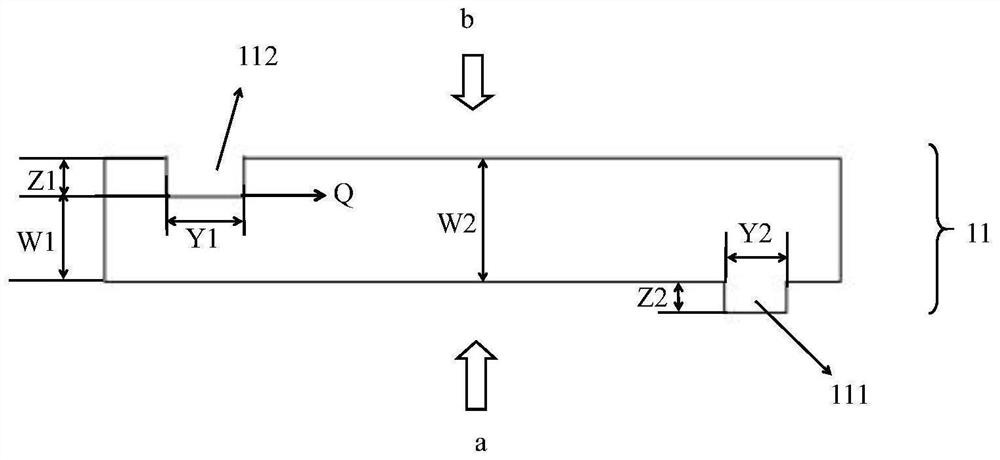

[0074] In the embodiment of the present invention, refer to image 3 , the battery sheet 11 has a lower surface a and an upper surface b, and includes a convex structure 111 and a concave structure 112;

[0075] The raised structure 111 is an outwardly raised raised structure formed on the lower surface a of the battery sheet 11;

[0076] The recessed structure 112 is an inwardly recessed recessed structure formed on the upper surface b of the battery sheet 11;

[0077] refer to image 3 , the lowest point Q of the concave structure 112 is lower than the plane where the upper surface b is located;

[0078] The protruding structure 111 and the concave structure 112 are respectively arranged at two ends of the battery sheet 11 .

[0079] Wherein, the concave structure and the convex structure can be arranged at both ends...

Embodiment 2

[0125] refer to Figure 5 , which shows a flow chart of the steps of a method for preparing a solar cell group provided by an embodiment of the present invention; the preparation method specifically includes the following steps:

[0126] Step 201, providing a cleaned silicon wafer.

[0127] In the embodiment of the present invention, the size of the silicon wafer is selected according to the number and size of the required solar cells of the solar cell group, and then the silicon wafer is ultrasonically cleaned with deionized water to make the surface of the silicon wafer dust-free.

[0128] Step 202, etching the lower surface of the silicon wafer to prepare a plurality of raised structures, wherein each raised structure is arranged side by side.

[0129] In the embodiment of the present invention, refer to Image 6 , showing the lower surface of the wafer, refer to Figure 8 , is the front view of the wafer. It can be seen that a plurality of raised structures prepared on...

Embodiment 3

[0163] refer to Figure 10 , which shows a flow chart of the steps of a method for preparing a solar cell group provided by an embodiment of the present invention; the preparation method specifically includes the following steps:

[0164] Step 301, providing a cleaned silicon wafer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com