Overheating protecting method of food processing machine

A food processing machine, overheating protection technology, applied in home appliances, applications, kitchen appliances, etc., can solve the problems of inability to meet national standards, high cost, safety hazards of self-resetting thermostats, etc., to reduce safety hazards and production. cost, the effect of reducing misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

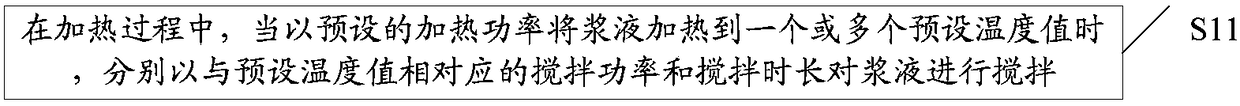

[0040] A method for overheating protection of a food processor, the food processor comprising: a crushing cup and a motor, the crushing cup is provided with a heating device, and a thermal fuse protector connected in series with the heating device is respectively provided at both ends of the heating device, such as figure 1 As shown, the method may include S11:

[0041] S11. During the heating process, when the slurry is heated to one or more preset temperature values with the preset heating power, the slurry is stirred with the stirring power and stirring time corresponding to the preset temperature values respectively.

[0042] In the embodiment of the present invention, the food processor may include: a crushing cup and a motor, the crushing cup is provided with a heating device, the crushing cup is provided with a crushing blade, the crushing blade is fixedly connected to the motor through the motor shaft, so that the motor can Drive the crushing blade to rotate to cru...

Embodiment 2

[0048] This embodiment provides a specific embodiment on the stirring method in the heating process on the basis of the first embodiment.

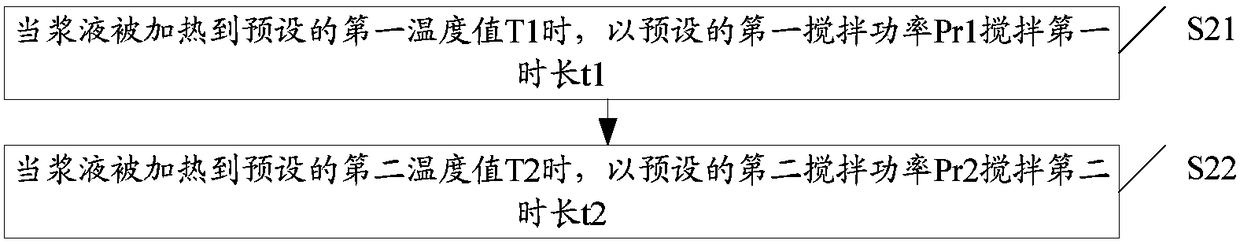

[0049] Optionally, as in figure 2 As shown, when the slurry is heated to one or more preset temperature values with the preset heating power, stirring the slurry with the stirring power and stirring time corresponding to the preset temperature value may include steps S21-S22:

[0050] S21. When the slurry is heated to a preset first temperature value T1, stir with a preset first stirring power Pr1 for a first time period t1;

[0051] S22. When the slurry is heated to the preset second temperature value T2, stir with the preset second stirring power Pr2 for a second time period t2;

[0052] Wherein, the second temperature value T2 is greater than the first temperature value T1.

[0053] In the embodiment of the present invention, a temperature sensor for detecting the temperature of the slurry may be installed on the crushing cup for r...

Embodiment 3

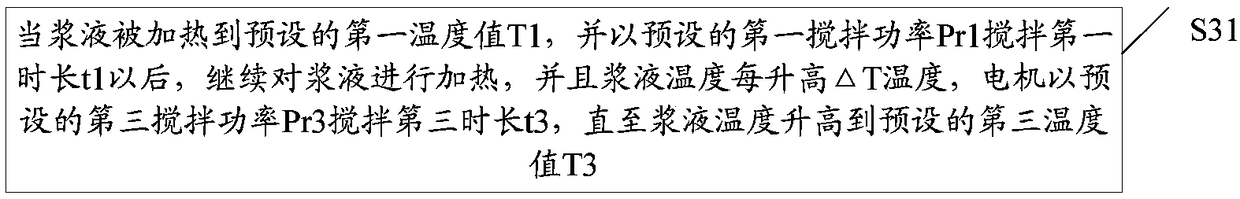

[0056] In this embodiment, on the basis of the second embodiment, the pulping parameters T1, T2, Pr1, Pr2, t1, and t2 of the above-mentioned embodiment are further limited.

[0057] Optionally, the first temperature value T1 satisfies: T1≤60°C; the second temperature value T2 satisfies: T2≥70°C.

[0058] In the embodiment of the present invention, under normal circumstances, rice materials are relatively easy to stick to the bottom. When the heating device is heated, the bottom temperature will be relatively high, and the actual water temperature cannot be effectively circulated due to the bottom sticking. Experiments show that when the bottom sticks, The actual water temperature is difficult to reach above 60°C, so it is recommended to stir with the motor before 60°C. In addition, when the bean slurry is generally heated to about 80°C, the protein nutrition is released most fully during the crushing and pulping process, so the heating temperature before crushing can be preset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com