Soybean peptide nutrient solution and preparation method thereof

A soybean polypeptide and nutrient solution technology is applied in food preparation, food ultrasonic treatment, food ingredients as taste improvers, etc. The effect of reducing the production of bitter peptides and enhancing the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

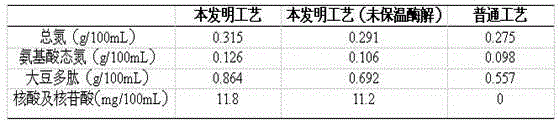

Image

Examples

Embodiment 1

[0021] (1) Cultivation of Aspergillus oryzae spore suspension: Inoculate the Aspergillus oryzae spore suspension in a liquid medium with a nitrogen source of 5% soybean flour and a carbon source of 1.5% glucose. , the medium needs to be sterilized at 115°C for 15 minutes, the initial pH is 6.0, and the inoculum size of spores is 2×10 5 g / mL.

[0022] (2) Preparation of enzymolysis solution: After the Aspergillus oryzae culture was completed, the mycelium was filtered out, and the culture solution was incubated at 35° C. for 3 hours to obtain an enzymolysis solution.

[0023] (3) Prepare mycelia broken self-solution: the filtered Aspergillus oryzae mycelium is ultrasonically broken, the ratio of mycelium weight to water volume (W / V) is 1:3, the ultrasonic break time is 5s each time, the interval is 5s, and the cycle After 30 times, the hyphae were broken and left to stand at 35°C for 8 hours to obtain a broken self-solution.

[0024] (4) The enzymatic solution and crushed sel...

Embodiment 2

[0029] (1) Aspergillus oryzae spore suspension culture: Inoculate the Aspergillus oryzae spore suspension in a liquid medium whose nitrogen source is 10% soybean flour and carbon source is 2% glucose. The culture temperature is 32°C, the speed is 180r / min, and the time is 60h , the medium needs to be sterilized at 115°C for 15 minutes, the initial pH is 6.5, and the inoculum size of spores is 5×10 5 g / mL.

[0030] (2) Preparation of enzymolysis solution: After the Aspergillus oryzae culture was completed, the mycelium was filtered out, and the culture solution was incubated at 40° C. for 5 hours to obtain an enzymolysis solution.

[0031] (3) Prepare mycelia broken self-solution: The filtered Aspergillus oryzae mycelium is ultrasonically broken, the ratio of mycelium weight to water volume (W / V) is 1:5, the time of ultrasonic breaking is 6s each time, the interval is 6s, and the cycle is repeated. 45 times, the hyphae were broken and left at 30°C for 12 hours to obtain a brok...

Embodiment 3

[0037] (1) Aspergillus oryzae spore suspension culture: Inoculate the Aspergillus oryzae spore suspension in a liquid medium whose nitrogen source is 3% soybean flour and carbon source is 0.5% glucose. The culture temperature is 30°C, the speed is 200r / min, and the time is 55h , the medium needs to be sterilized at 115°C for 15 minutes, the initial pH is 6.5, and the inoculum size of spores is 1×10 5 g / mL.

[0038] (2) Preparation of enzymolysis solution: After the Aspergillus oryzae culture was completed, the mycelium was filtered out, and the culture solution was incubated at 30° C. for 2 hours to obtain an enzymolysis solution.

[0039](3) Preparation of mycelia broken self-solution: the filtered Aspergillus oryzae mycelium was subjected to ultrasonic crushing, the ratio of mycelial weight to water volume (W / V) was 1:1, the ultrasonic crushing conditions were 10s each time, the interval was 10s, and the cycle was 60 The second time, after the mycelium was broken, it was le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com