Preparation method of PEG-CuMo2S3 nano material and nano material

A technology of peg-cumo2s3 and nanomaterials, applied in nanotechnology, nanotechnology, nanomedicine, etc., can solve the problems of complicated preparation methods, affecting the health of patients, easy to block blood vessels, etc. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

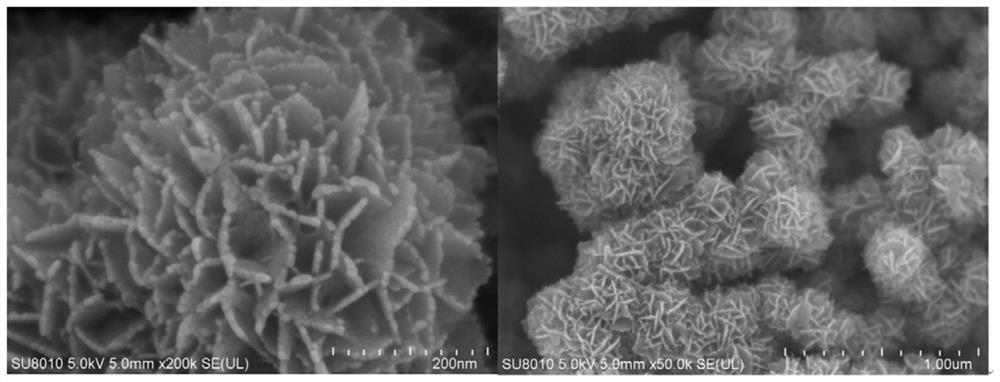

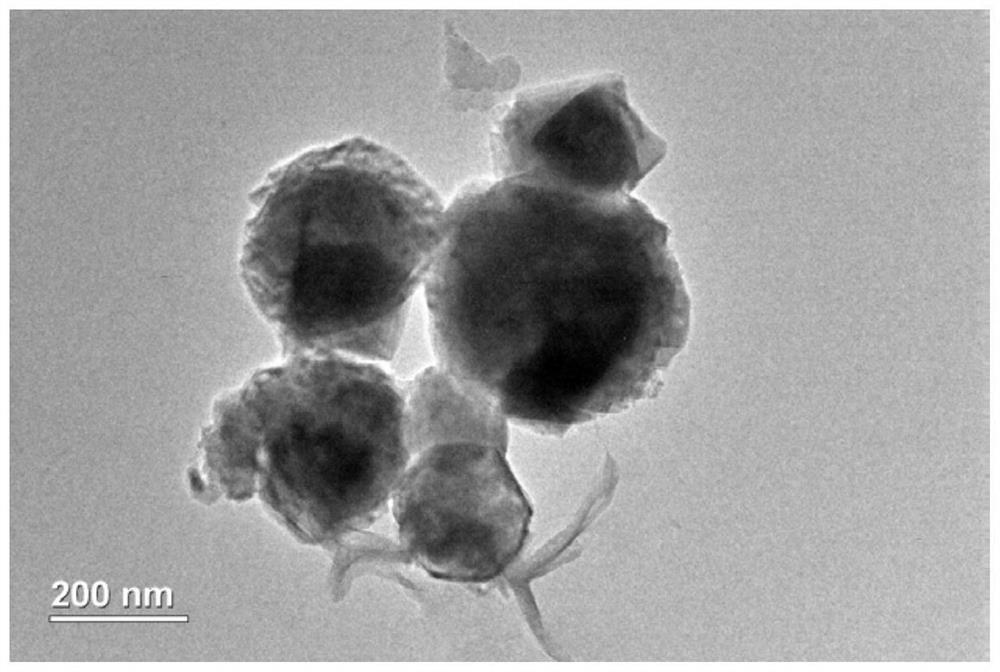

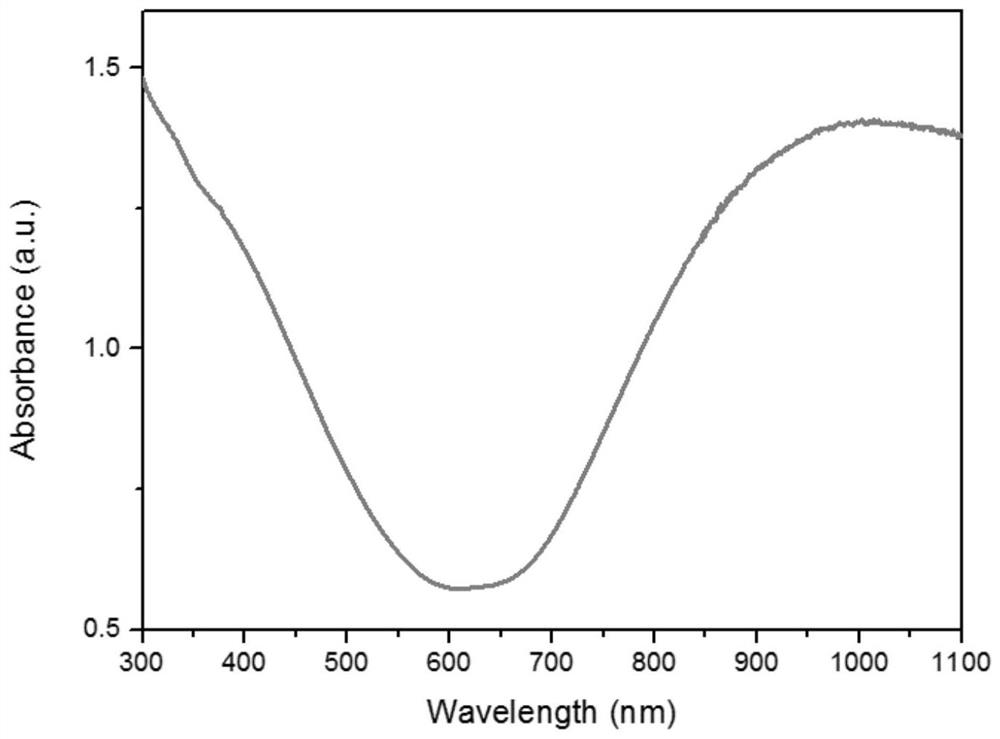

[0027] A PEG-CuMo 2 S 3 The preparation method of nanomaterials, copper acetate 0.5g, thioacetamide 0.2g, sodium molybdate 1g, PEG-400 30mL, deionized water 30mL mixed for hydrothermal reaction, solid product is separated from the reaction solution and washed, Dry to obtain the PEG-CuMo 2 S 3 nanomaterials.

[0028] Further, the heating temperature is 200° C., and the reaction time is 24 hours.

[0029] Further, the method of separating the solid product is centrifugation, and the centrifugation speed is 10000r / min.

[0030] Further, the solvent for cleaning the solid product is ethanol.

[0031] Further, the drying temperature for drying the solid product is 80°C.

[0032] A PEG-CuMo 2 S 3 Nanomaterials are prepared from the following raw materials: 0.5g copper acetate, 0.2g thioacetamide, 1g sodium molybdate, 30mL PEG-400, and 30mL deionized water. PEG-CuMo 2 S 3 The nanomaterial is composed of the above-mentioned PEG-CuMo 2 S 3 The preparation method of the nan...

Embodiment 2

[0035] A PEG-CuMo 2 S 3 The preparation method of nanomaterials, copper acetate 0.1g, thioacetamide 0.1g, sodium molybdate 0.5g, PEG-400 10mL, deionized water 10mL are mixed for hydrothermal reaction, and the solid product is separated from the reaction solution and washed , dry to obtain the PEG-CuMo 2 S 3 nanomaterials.

[0036] Further, the heating temperature is 240° C., and the reaction time is 6 hours.

[0037] Further, the method of separating the solid product is centrifugation, and the centrifugation speed is 8000r / min.

[0038] Further, the solvent for cleaning the solid product is 75% ethanol.

[0039] Further, the drying temperature for drying the solid product is 60°C.

[0040] A PEG-CuMo 2 S 3 The nanomaterials are prepared from the following raw materials: 0.1 g of copper acetate, 0.1 g of thioacetamide, 0.5 g of sodium molybdate, 10 mL of PEG-400, and 10 mL of deionized water. PEG-CuMo 2 S 3 The nanomaterial is composed of the above-mentioned PEG-CuM...

Embodiment 3

[0042] A PEG-CuMo 2 S 3 The preparation method of nanomaterials, copper acetate 0.72g, thioacetamide 0.5g, sodium molybdate 2g, PEG-400 50mL, and deionized water 50mL are mixed for hydrothermal reaction, and the solid product is separated from the reaction solution and washed, Dry to obtain the PEG-CuMo 2 S 3 nanomaterials.

[0043] Further, the heating temperature is 150° C., and the reaction time is 48 hours.

[0044] Further, the method of separating the solid product is centrifugation, and the centrifugation speed is 12000r / min.

[0045] Further, the solvent for washing the solid product is deionized water.

[0046] Further, the drying temperature for drying the solid product is 80°C.

[0047] A PEG-CuMo 2 S 3 Nanomaterials are prepared from the following raw materials: 0.72g of copper acetate, 0.5g of thioacetamide, 2g of sodium molybdate, 50mL of PEG-400, and 50mL of deionized water. PEG-CuMo 2 S 3 The nanomaterial is composed of the above-mentioned PEG-CuMo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com