Charcoal load nanometer zero-valent iron activated sodium persulfate system and preparation and application thereof

A nano-zero-valent iron and sodium persulfate technology, which is applied in chemical instruments and methods, pathogenic microorganism wastewater treatment, special compound water treatment, etc., can solve the problems of difficult recycling and reuse, low efficiency of sodium persulfate, etc., and achieve enhanced The effect of reusability, high utilization rate, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

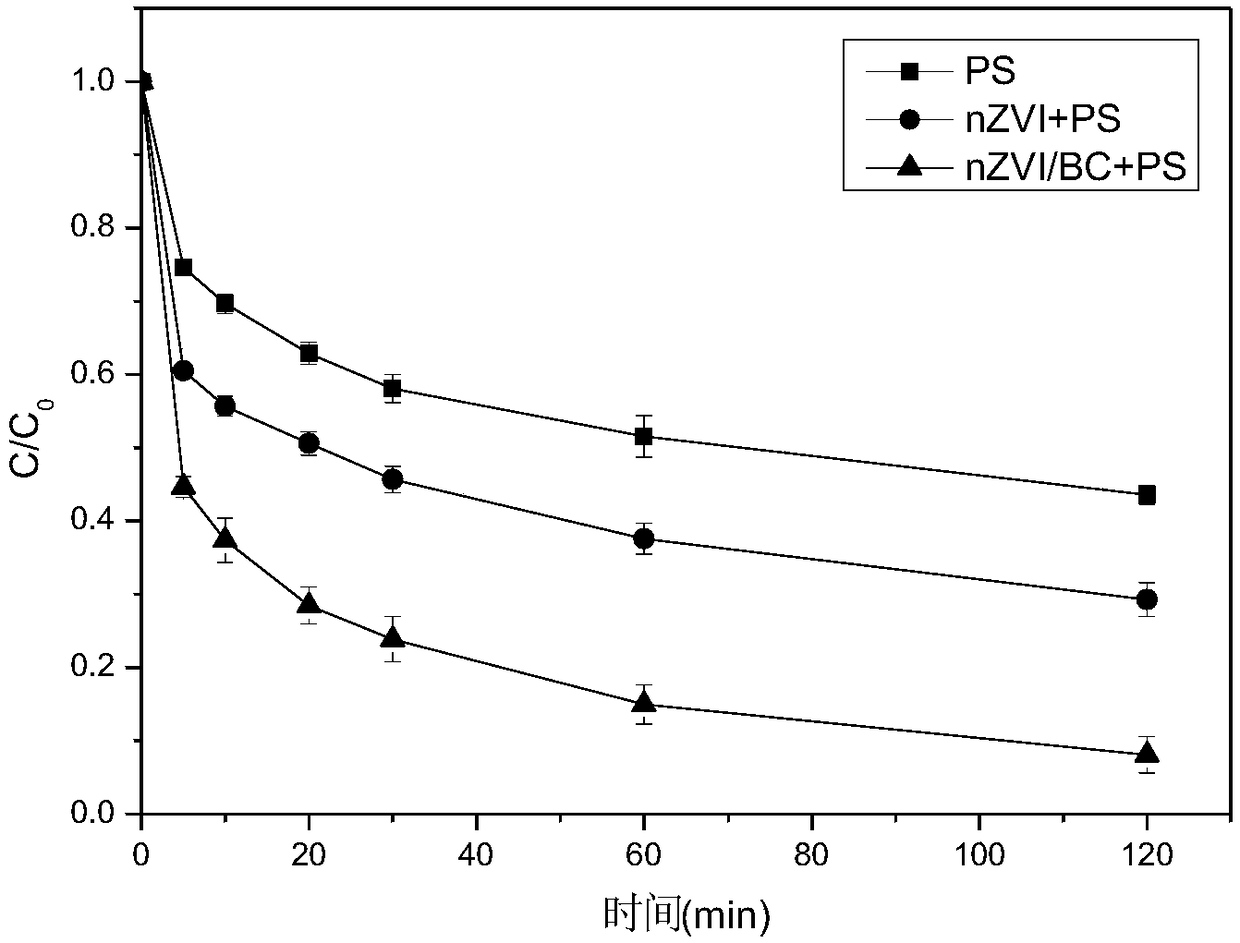

[0036]The method for preparing biochar-supported nanometer zero-valent iron activating and activating sodium persulfate oxidation system (nZVI / BC-PS) according to the present invention comprises the steps of adding sodium borohydride dropwise under the protection of nitrogen by using a liquid phase reduction method Reducing ferrous sulfate into nano-zero-valent iron, in the high-speed agitated nano-zero-valent iron biochar mixed liquid, tiny nano-zero-valent iron particles continue to adhere to the shape and structure of the biochar. The obtained biochar-loaded nano-zero-valent iron activation material is evenly dispersed in the organic-contaminated solution, and sodium persulfate solution is added to the solution to form the nZVI / BC-PS oxidation system, and the nano-zero-valent iron adhered to the biochar It can effectively activate sodium persulfate to produce strong oxidizing sulfate radicals and hydroxyl radicals. The nZVI / BC-PS oxidation system can remove various refracto...

Embodiment 1

[0040] A preparation method for activated sodium persulfate system loaded with nanometer zero-valent iron on biochar, comprising the following steps:

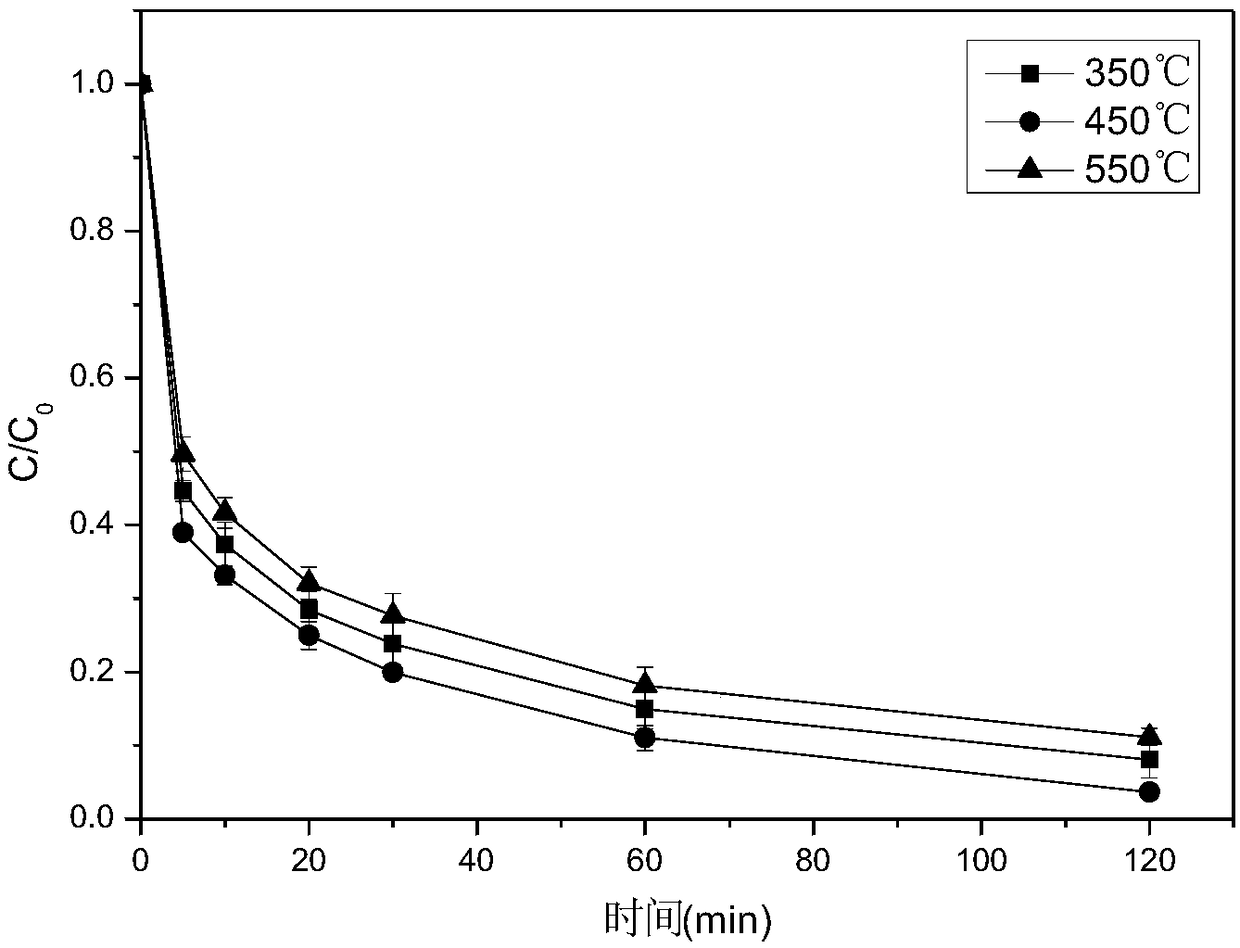

[0041] (1) Cut the peanut shells into pieces and burn them in an anaerobic muffle furnace at 350°C for 2 hours. After pyrolysis and cooling, they are ground and pulverized to make powdery biochar Ⅰ;

[0042] (2) Acidify the biochar with high-grade hydrochloric acid with a mass concentration of 10% for 12 hours, remove the ash, wash it with deionized water three times, and dry it in an oven at 60°C to obtain powdered biochar II;

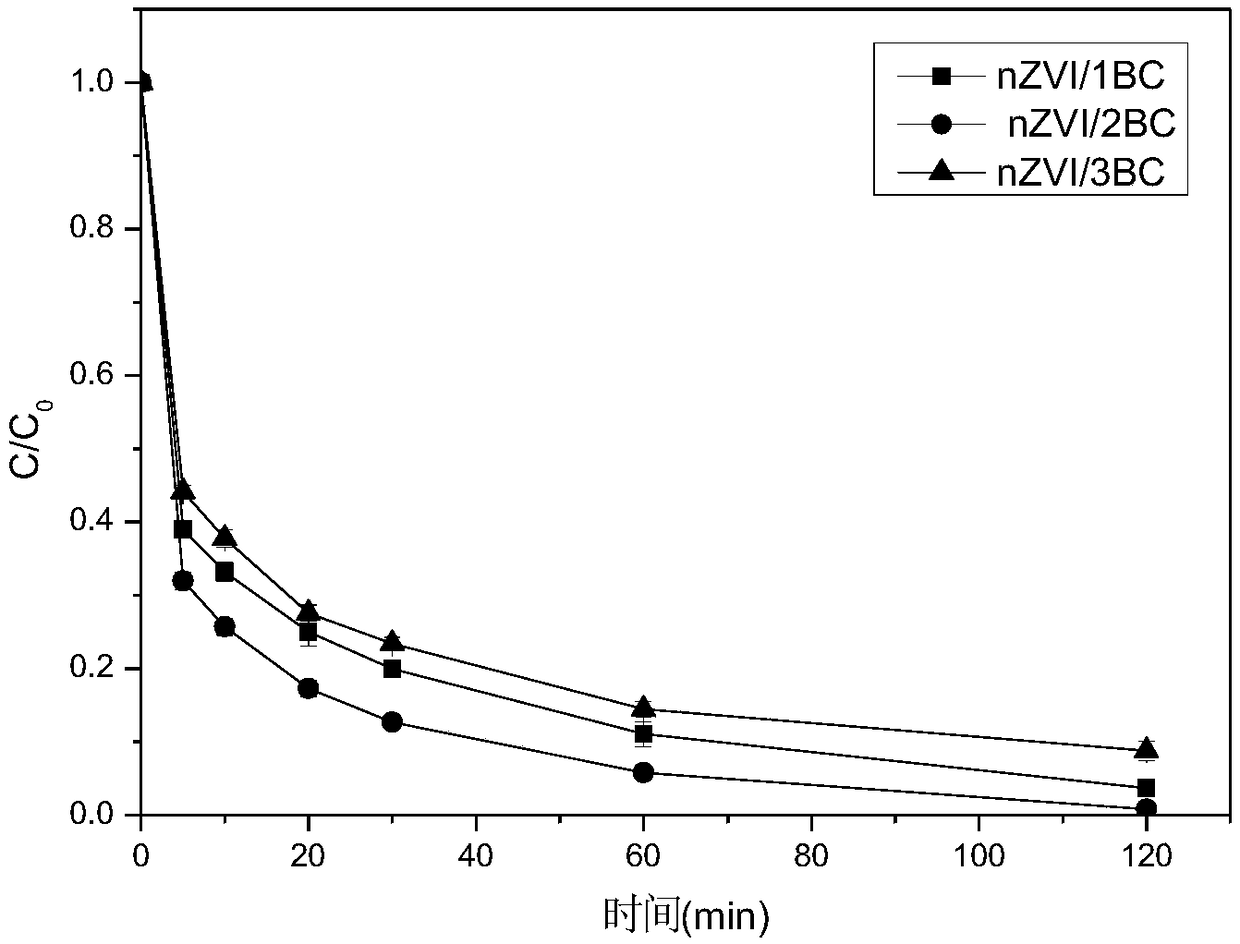

[0043] (3) Weigh 3.0g FeSO 4 ·7H 2 O was dissolved in 20 mL of deionized water stripped with nitrogen, then poured into a reaction vessel containing 1.0 g of powdered biochar II, stirred continuously under nitrogen atmosphere at a stirring rate of 150 r / min, and after mixing evenly, 60 mL of water ethanol, keep V 无水乙醇 :V 水 = 3:1, then add 50mL 20mg / L NaBH dropwise at a rate of 1-2 drops per second ...

Embodiment 2

[0048] A preparation method for activated sodium persulfate system loaded with nanometer zero-valent iron on biochar, comprising the following steps:

[0049] (1) Cut the peanut shells into pieces and burn them in an anaerobic muffle furnace at 450°C for 2 hours. After pyrolysis and cooling, they are ground and pulverized to make powdery biochar;

[0050] (2) Acidify the biochar with high-grade hydrochloric acid with a mass concentration of 10% for 12 hours, remove the ash, wash it with deionized water for 3 times, and dry it in an oven at 60°C for later use;

[0051] (3) Weigh 3.0g FeSO 4 ·7H 2 O was dissolved in 20 mL of deionized water stripped with nitrogen, then poured into a reaction vessel containing 1.0 g of powdered biochar II, stirred continuously under nitrogen atmosphere at a stirring rate of 150 r / min, and after mixing evenly, 60 mL of water ethanol, keep V 无水乙醇 :V 水 = 3:1, then add 50mL 20mg / L NaBH dropwise at a rate of 1-2 drops per second using a separatory...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com