Friction material composition, and friction material and friction member using said friction material composition

A friction material and composition technology, which is applied to friction linings, gear shifting mechanisms, chemical instruments and methods, etc., can solve the problems of reduced thermal conductivity, increased brake vibration, and inability to diffuse heat at the friction interface, and achieves less brake vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

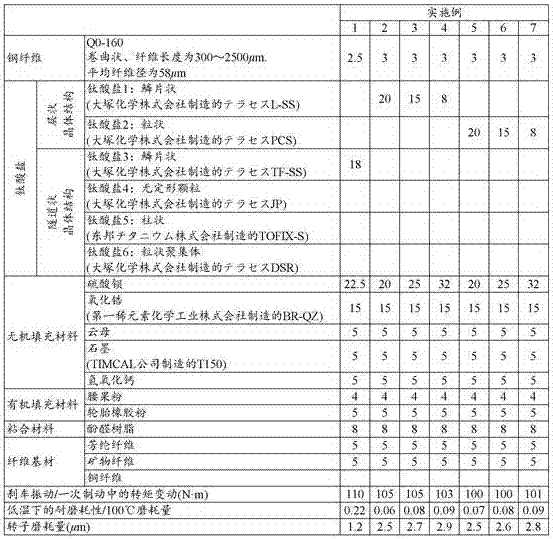

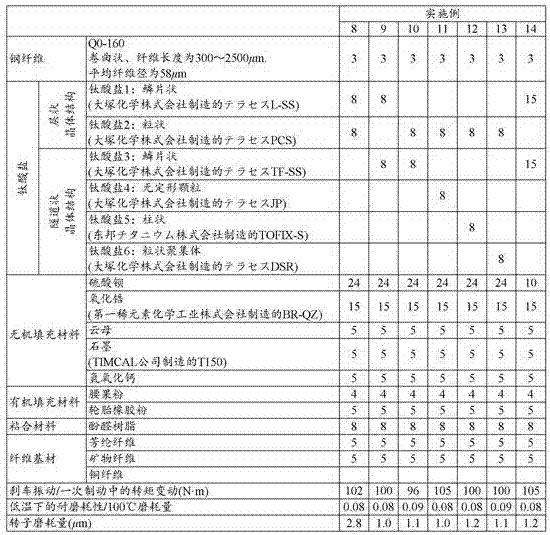

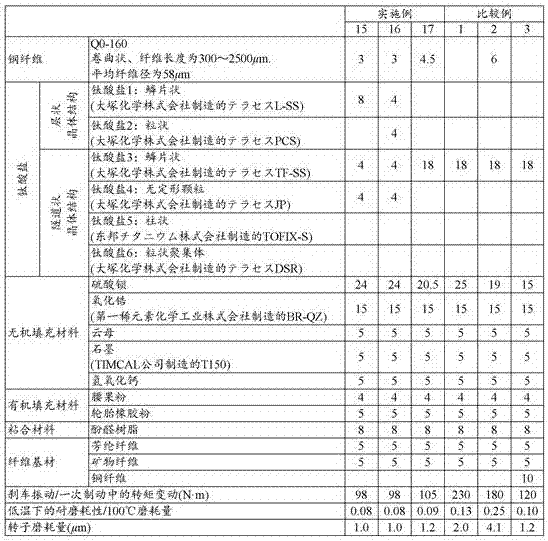

Embodiment 1~17 and comparative example 1~3

[0066] (Manufacturing of disc brake pads)

[0067] The materials were blended according to the blending ratios shown in Tables 1-3, and the friction material compositions of Examples 1-17 and Comparative Examples 1-3 were obtained. The blending ratios in the table are % by mass. The steel fibers used in Examples and Comparative Examples used "Q0-160" (curled, fiber length 300-2500) manufactured by SINOMA Corporation. mu m, the average fiber diameter is 58 mu m). In addition, the fiber length was measured by measuring the fiber length of 100 fibers using the microscope manufactured by Keyence Corporation. The average fiber diameter measured the fiber diameters of 50 fibers using a microscope manufactured by Keyence Co., Ltd., and made the average value the average fiber diameter.

[0068] The friction material composition was mixed using a Ladyge mixer (manufactured by Mazubo Corporation, trade name: Ladyge mixer M20), and the resulting mixture was preformed with a press mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com